The structure and manufacturing process of the electronic product casing panel

A technology of electronic products and manufacturing process, which is applied in the direction of casing/cabinet/drawer parts, metal casing, etc., which can solve the problems that the radiation protection of the casing cannot be achieved, the strength of the casing panel is reduced, and the radiation protection performance is not good. , to achieve the effect of simple processing, convenient structure processing and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

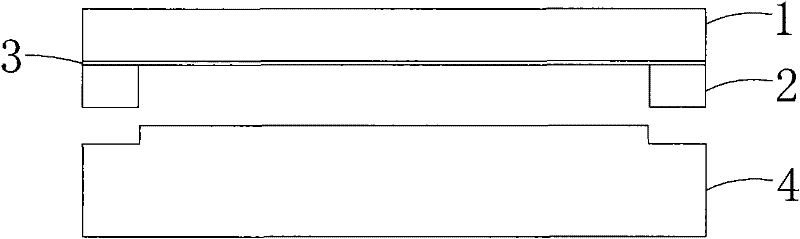

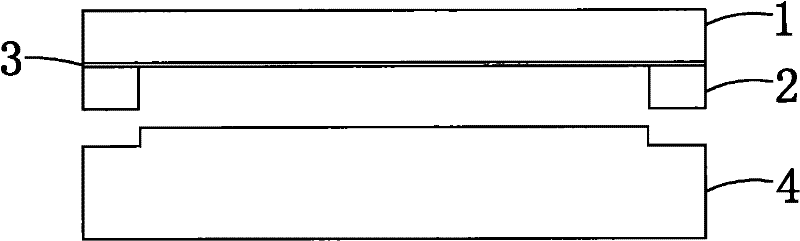

[0020] Embodiment: A structure of an electronic product 4 casing panel and a manufacturing method thereof:

[0021] A. Carry out hardening treatment (such as anodizing) to the outer surface of the metal panel 1 first. The metal panel is an aluminum plate, a magnesium plate, an alloy plate or a stainless steel plate, etc., and the thickness of the metal panel is 0.15-10 mm.

[0022] B. After the outer surface of the metal panel is hardened, the metal panel is punched to form the metal panel into the desired shape and size.

[0023] C. Roughen the inner surface of the metal panel to form a roughened surface.

[0024] D. After roughening, clean the metal panel to remove dust particles and residual oil after roughening.

[0025] E. The metal panel and the hot melt adhesive film 3 are heated to a set temperature and maintained at the set temperature for a set time under a set pressure condition, and then cooled to finally complete the roughened surface of the metal panel and The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com