heating appliances

A technology for heating appliances and heating parts, which is applied in the direction of heating appliances for therapeutic treatment, cooling appliances for therapeutic treatment, contraceptives, etc., and can solve the problems of inability to provide heating effects, insufficient heat production by chemical heaters, and exothermic compositions. Difficulty in contact with air and other issues to achieve a stable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0111] (4) Preparation of heat generating part

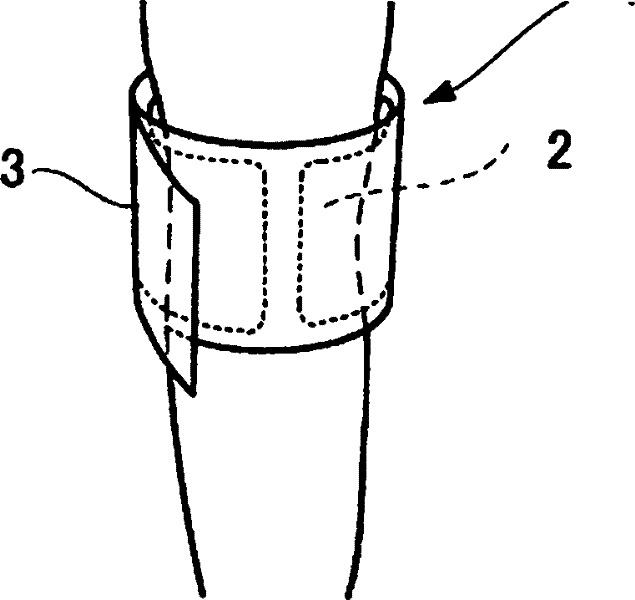

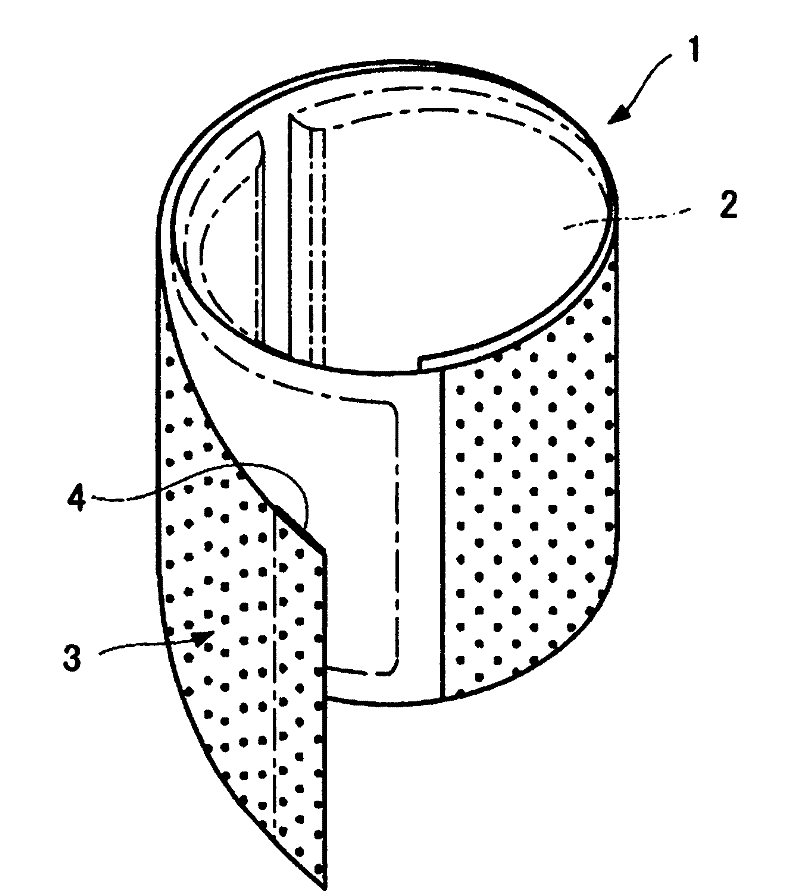

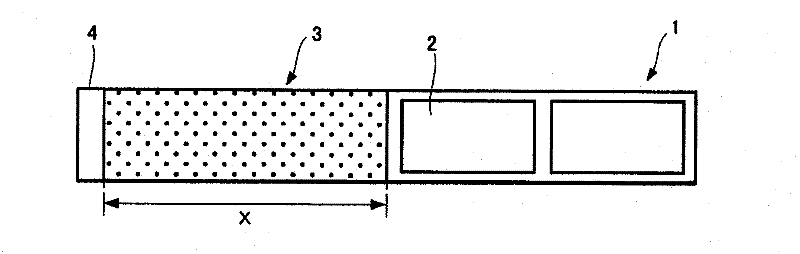

[0112] The heat generating portion described above is obtained by bonding the first and second sheets in such a manner that the heat releasing composition is enclosed in one or more parts. When the first and second sheets respectively use laminates, the first and second sheets are bonded to each other such that the non-woven fabric forming each laminate faces outward (that is, the side that is in contact with the closed exothermic composition) on the contrary). At this time, all parts of the heat generating portion except the respective parts were bonded so that the respective parts enclosed with the exothermic composition were formed. For example, in image 3 , the first and second sheets are bonded to each other in the region of the heat generating portion 1 other than the member 2 .

[0113] Examples of usable bonding methods include, but are not limited to, the aforementioned methods of thermal bonding and bonding of resi...

Embodiment

[0132] The present invention will be described in more detail below with reference to the following Examples and Comparative Examples; however, the present invention is not limited to these Examples.

[0133] Examples and Comparative Examples

[0134] Manufacturing has image 3 A heating appliance of the structure shown.

[0135]

[0136] 1) Exothermic composition

[0137] The exothermic composition was prepared by mixing iron powder with a particle size of 50 μm, activated carbon with a particle size of 200 μm, salt with a particle size of 380 μm, water, vermiculite with a particle size of 100 μm, and acrylic acid polymer with a particle size of 380 μm. The amounts of iron powder, activated carbon, sodium chloride, water, vermiculite and sodium polyacrylate in the exothermic composition were 55%, 13%, 1%, 26%, 3% and 2% by mass, respectively.

[0138] The exothermic composition was prepared according to the method described above.

[0139] 2) First sheet

[0140] First...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com