Purple berry beverage and preparation method thereof

A technology for berries and beverages, applied in the field of purple berry beverages and their preparation, can solve the problems of seasonal harvest restrictions, difficulty in long-term storage, and inability for consumers to eat all year round, and achieve convenient operation, broad market application prospects, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

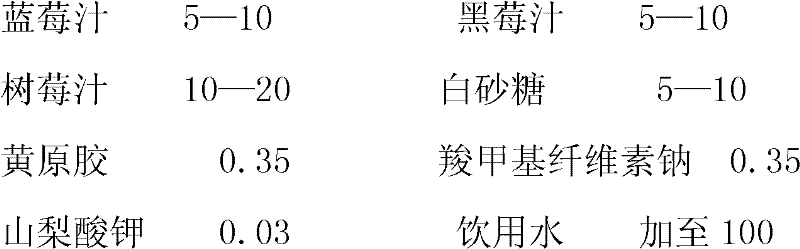

[0022] The purple berry beverage provided by the present embodiment is made up of the following components in weight percentage:

[0023]

[0024]

[0025] The purple berry beverage preparation method provided by the present embodiment comprises the following steps carried out in order:

[0026] 1) Wash blueberries, blackberries and raspberries respectively to make blueberry juice, blackberry juice and raspberry juice, then weigh 5 kg of blueberry juice, 5 kg of blackberry juice and 10 kg of raspberry juice and dilute with appropriate amount of water, then use 120 mesh sieve for later use;

[0027] 2) Dissolve 5 kg of white granulated sugar with an appropriate amount of water, then filter through a 120-mesh sieve for later use;

[0028] 3) Add 0.35 kg of xanthan gum and 0.35 kg of sodium carboxymethylcellulose into an appropriate amount of warm water at 40-60°C, then vigorously stir to dissolve them, and then use a colloid mill to refine the pulp;

[0029] 4) The above...

Embodiment 2

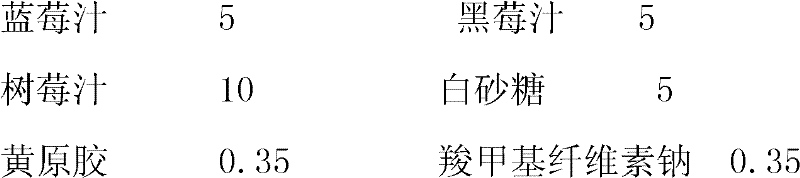

[0032] The purple berry beverage provided by the present embodiment is made up of the following components in weight percentage:

[0033]

[0034] The purple berry beverage preparation method provided by the present embodiment comprises the following steps carried out in order:

[0035] 1) Wash blueberries, blackberries and raspberries respectively to make blueberry juice, blackberry juice and raspberry juice, then weigh 10 kg of blueberry juice, 10 kg of blackberry juice and 20 kg of raspberry juice and dilute with appropriate amount of water, then use 120 mesh sieve for later use;

[0036] 2) Dissolve 10 kg of white granulated sugar with an appropriate amount of water, then filter through a 120-mesh sieve for later use;

[0037] 3) Add 0.35 kg of xanthan gum and 0.35 kg of sodium carboxymethylcellulose into an appropriate amount of warm water at 40-60°C, then vigorously stir to dissolve them, and then use a colloid mill to refine the pulp;

[0038] 4) The above-mentione...

Embodiment 3

[0041] The purple berry beverage provided by the present embodiment is made up of the following components in weight percentage:

[0042]

[0043] The purple berry beverage preparation method provided by the present embodiment comprises the following steps carried out in order:

[0044] 1) Wash blueberries, blackberries and raspberries respectively to make blueberry juice, blackberry juice and raspberry juice, then weigh 8 kg of blueberry juice, 8 kg of blackberry juice and 15 kg of raspberry juice and dilute with appropriate amount of water, then use 120 mesh sieve for later use;

[0045] 2) Dissolve 8 kg of white granulated sugar with an appropriate amount of water, then filter through a 120-mesh sieve for later use;

[0046] 3) Add 0.35 kg of xanthan gum and 0.35 kg of sodium carboxymethyl cellulose into an appropriate amount of warm water at 40-60°C, then vigorously stir to dissolve them, and then use a colloid mill to refine the pulp;

[0047] 4) The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com