A tamping coke oven riser layout structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

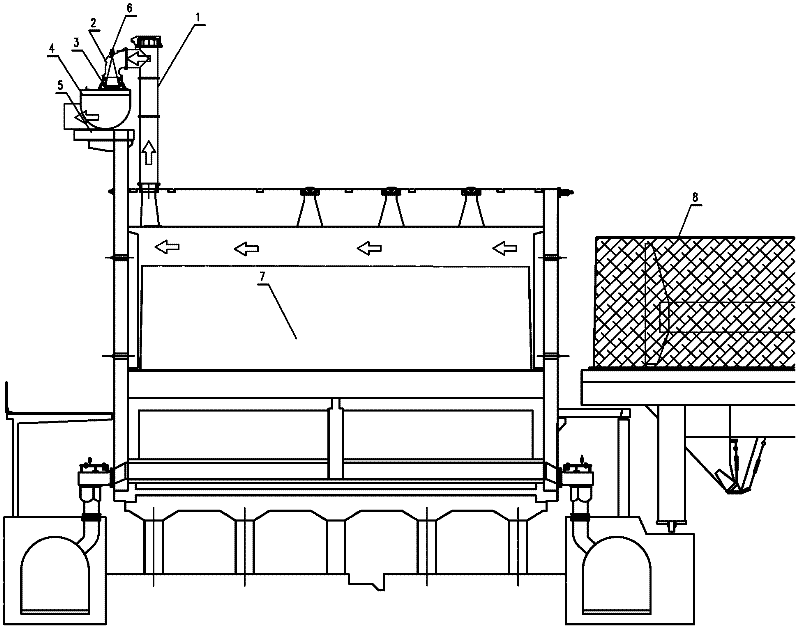

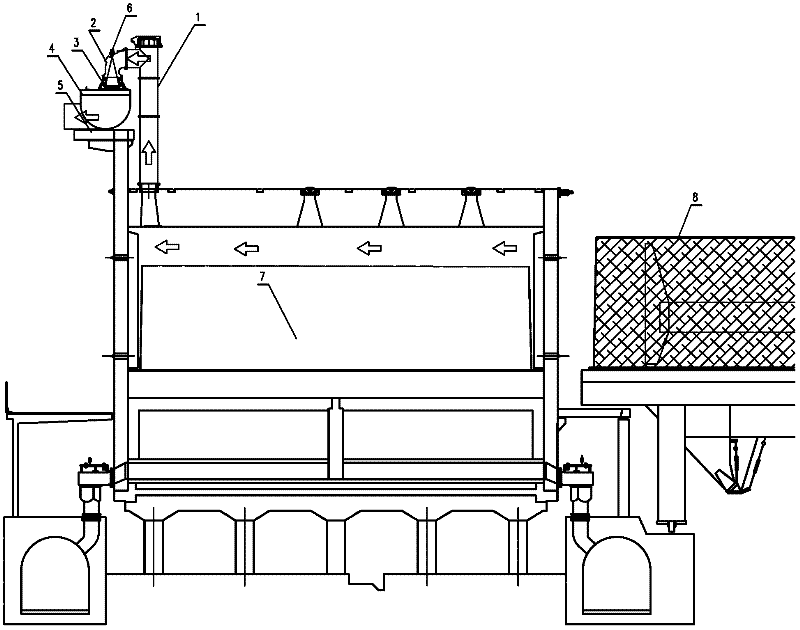

[0010] The arrangement structure of the rising pipe of the tamping coke oven of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings.

[0011] See figure 1 , tamping coke oven rising pipe layout structure, rising pipe 1 is arranged on the coke side of the top of the coke oven, rising pipe 1 is connected with bridge pipe 2, valve body 3 and gas collecting pipe 4 arranged on the coke side in turn, and bridge pipe 2 is A high-pressure ammonia water injection device 6 is installed, and the gas collecting pipe 4 is installed on the gas collecting pipe bracket 5; the tamping coal charging machine 8 is installed on the side of the coke oven machine.

[0012] When the tamping coal charging machine 8 is charging coal, coal cakes will produce a large amount of flue gas in the process of entering the coke oven carbonization chamber 7. Through the coke-side ascending pipe 1, bridge pipe 2, and valve body 3, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com