Horizontal liquid fermentation tank

A liquid fermentation, horizontal technology, applied in the field of fermentation tanks, can solve the problems of inability to grow and metabolize production bacteria, limited application scope, and inability to apply, and achieves good gas-liquid mixing effect, improves fermentation efficiency, and saves electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

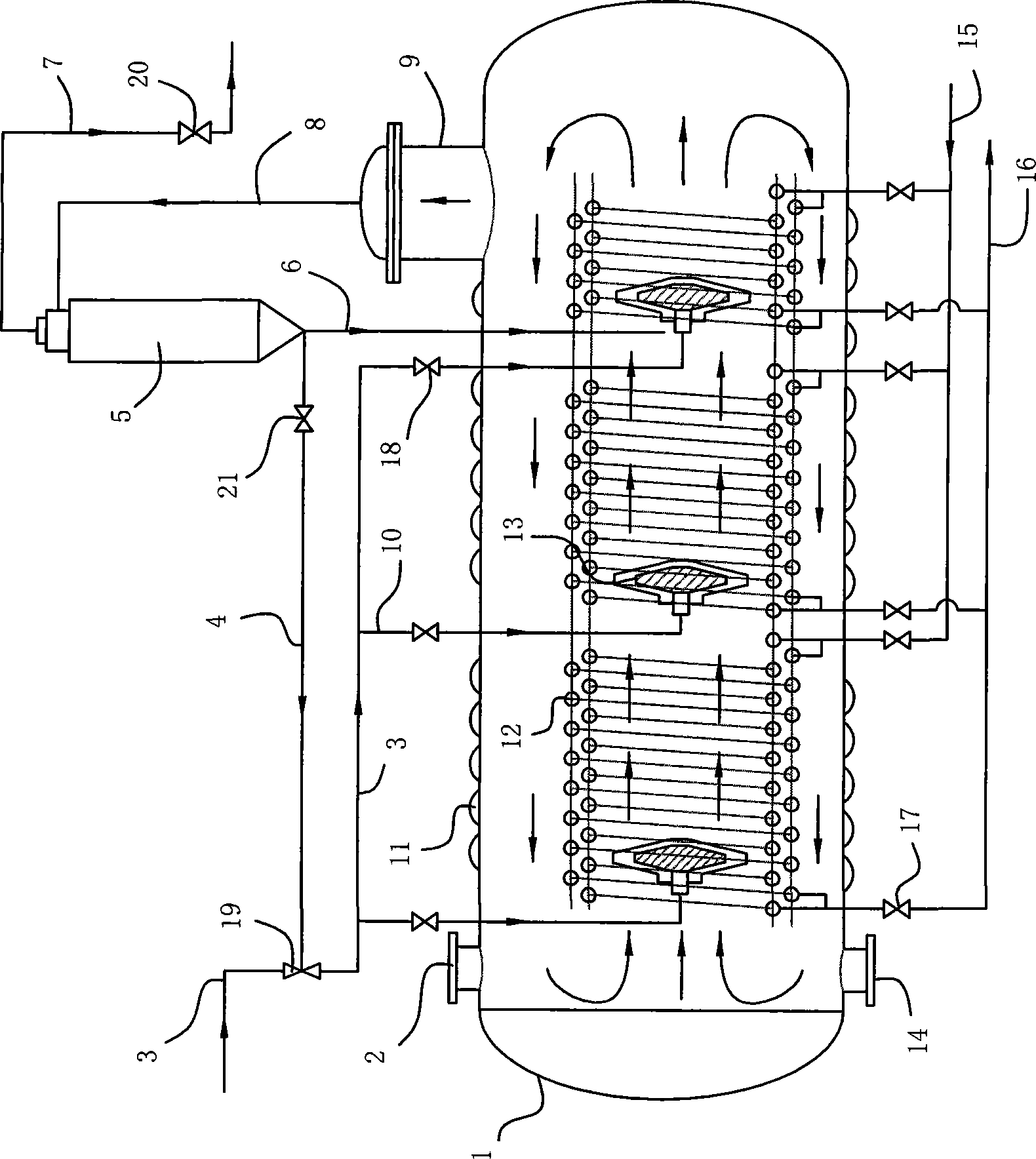

[0018] Such as figure 1 As shown, a horizontal liquid fermentation tank includes a tank body 1, a cooling system, an air intake system, an exhaust system, and an air return system. The top of the front end of the tank is provided with a feed liquid inlet 2, and the top of the rear end is provided with a gas outlet The gas cap 9, the bottom of the front end of the tank body 1 is provided with a feed liquid outlet 14, and the tank body 1 is also provided with various necessary pipeline connections. For the convenience of discharging, the fermenter can be slightly inclined to the outlet 14 when it is installed, which is also conducive to Fermentation gas gathers toward gas cap 9. The cooling system includes an external cooling device formed by a thin layer annular belt attached to the outer surface of the fermenter, a cooling device arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com