Optimized Design of Low Pressure Oil Circuit Diesel Filter System

A diesel filter, optimized design technology, applied in the direction of charging system, mechanical equipment, machine/engine, etc., can solve the problems of complex structure, increase the manufacturing cost of the engine, over-temperature damage of the starter motor, etc., to simplify the external structure, The effect of meeting functional requirements and preventing internal circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

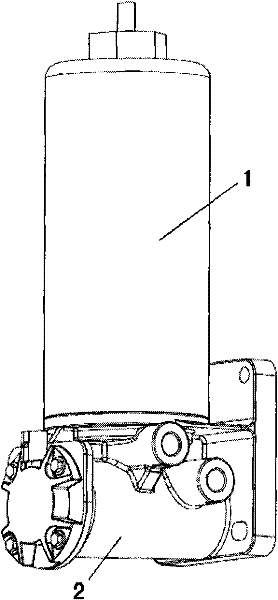

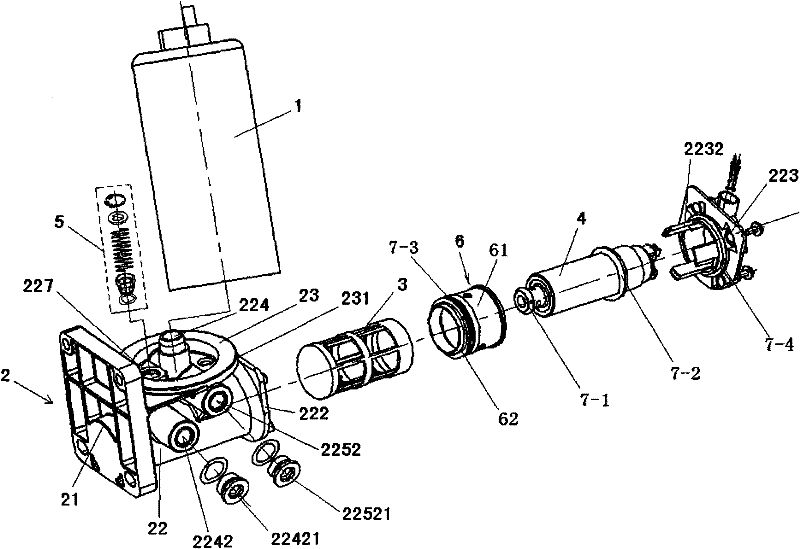

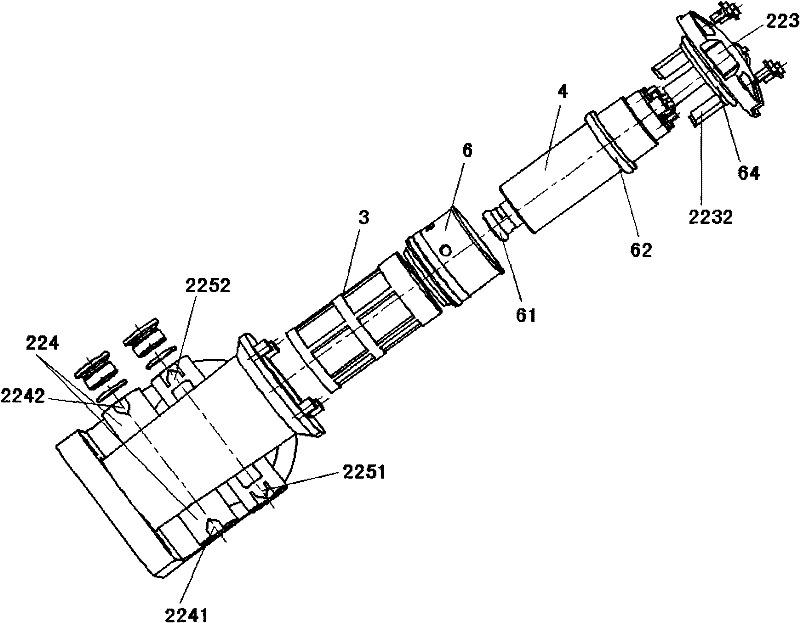

[0023] see Figure 1 ~ Figure 4 . The low-pressure oil circuit diesel oil filter system optimized in the present invention includes a filter 1, and also includes a low-pressure oil circuit automatic emptying device connected with the filter as a whole; the low-pressure oil circuit automatic emptying device includes a filter Device base 2, strainer 3, priming pump 4, and one-way valve assembly 5. In this embodiment, the filter base 2 includes a connection seat 21, a mounting portion 22 disposed on the base, and a connecting piece 23 disposed on the mounting portion; the interior of the mounting portion 22 is set as a cavity 221, One end opening 222, the opening is provided with an end cover 223; the side wall of the installation part is provided with at least one pair of oil inlet and oil outlet, the left and right sides of the side wall of the installation part described in this embodiment Each is respectively provided with two oil inlets 2241, 2242 and two oil outlets 2251,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com