System and method capable of controlling viscosity of electric spindle lubricating fluid

A technology of electric spindle and lubricating fluid, which is applied in the direction of control/adjustment system, viscosity control, non-electric variable control, etc. It can solve the problems of excessive spindle precision error, worn spindle life, and the viscosity of lubricating fluid that cannot be controlled artificially. The effect of strong ability, improving operation stability and expanding the scope of applicable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

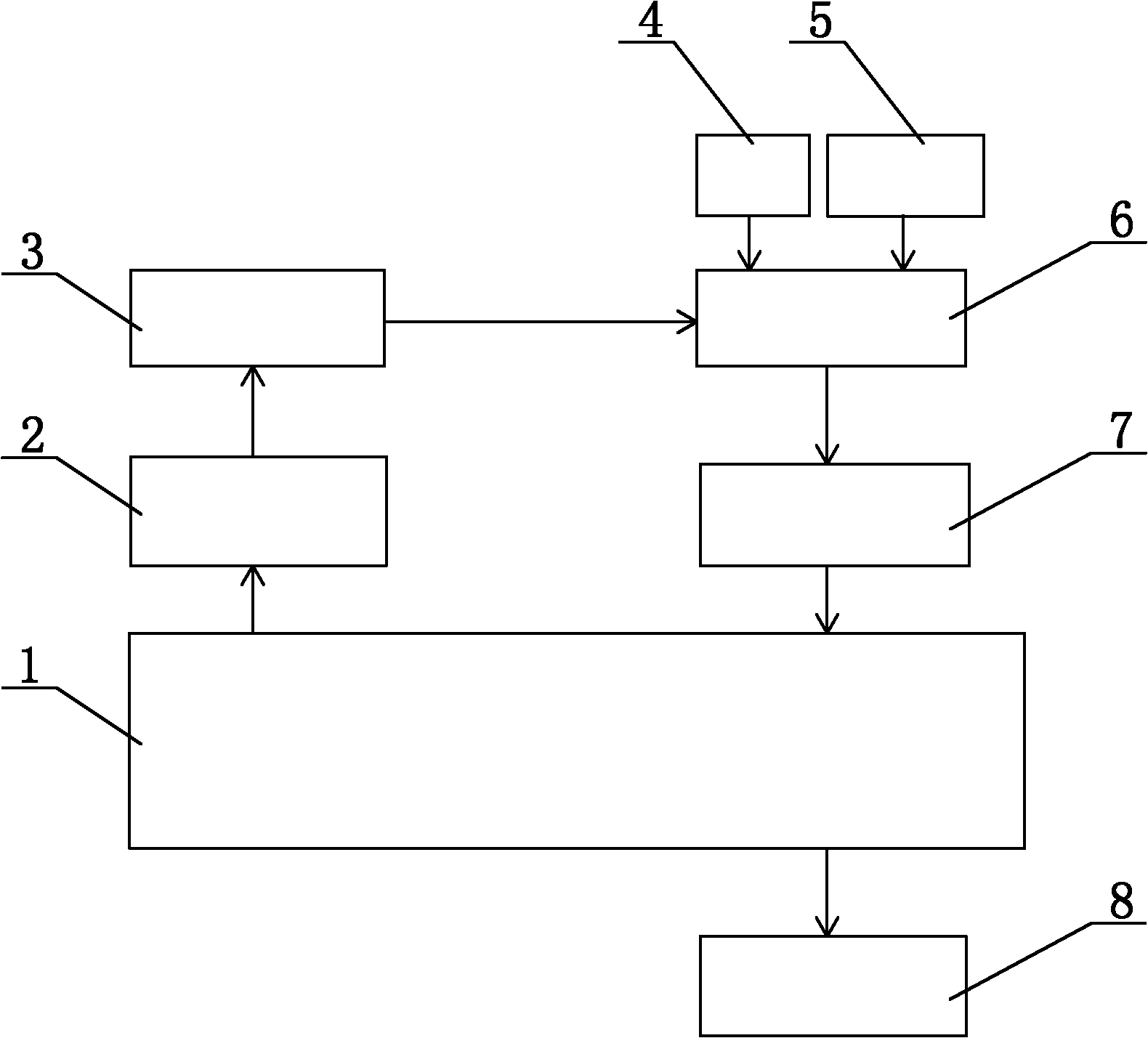

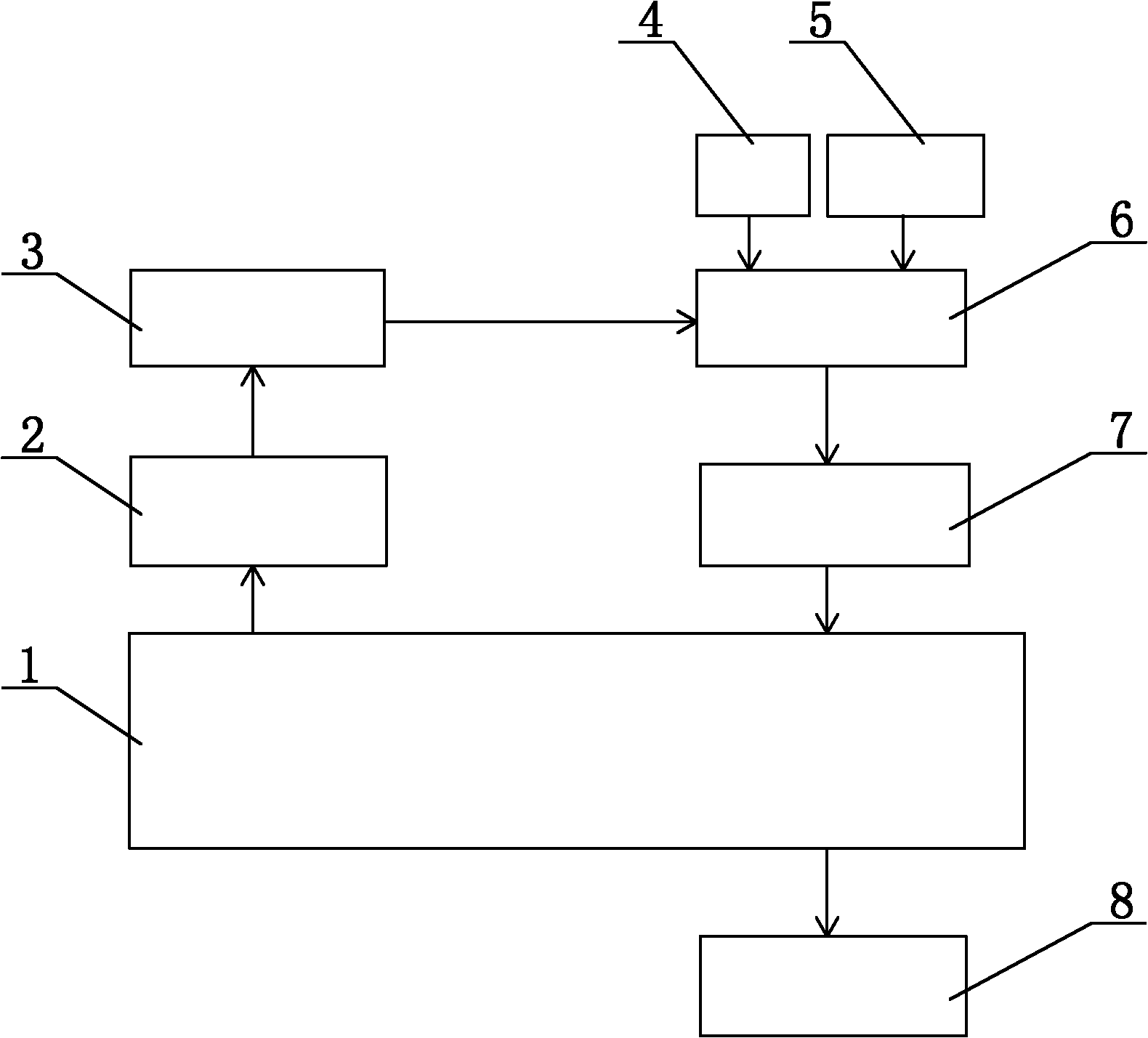

[0041] As shown in the drawings, the present invention discloses a system capable of controlling the viscosity of the electric spindle lubricating fluid, including an electric spindle 1, a monitoring module 2, a control module 3, a base fluid tank 4, a tackifier tank 5, and a liquid distribution module 6 , a liquid supply module 7 and a liquid return module 8 .

[0042] The monitoring module 2 is composed of various sensors, including a spindle load sensor, a speed sensor, a temperature sensor, a displacement sensor, etc., and each sensor monitors the spindle running indicators such as the load, speed, oil film thickness, oil film temperature, and axis trajectory of the electric spindle 1, and The monitoring signal is obtained, and then the monitoring signal is sent to the control module 3 .

[0043] Among them, the load sensor is used to monitor the load on the main shaft, and strain gauges, pressure sensors, etc. can be selected. The speed sensor is used to monitor the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com