Ultra-light and flexible solar cell array and its manufacturing method

A solar cell array and solar cell technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of inapplicability of flexible surfaces, limited use range, energy consumption of consumables, etc., reaching a broad ground application market, The effect of light weight and increased structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

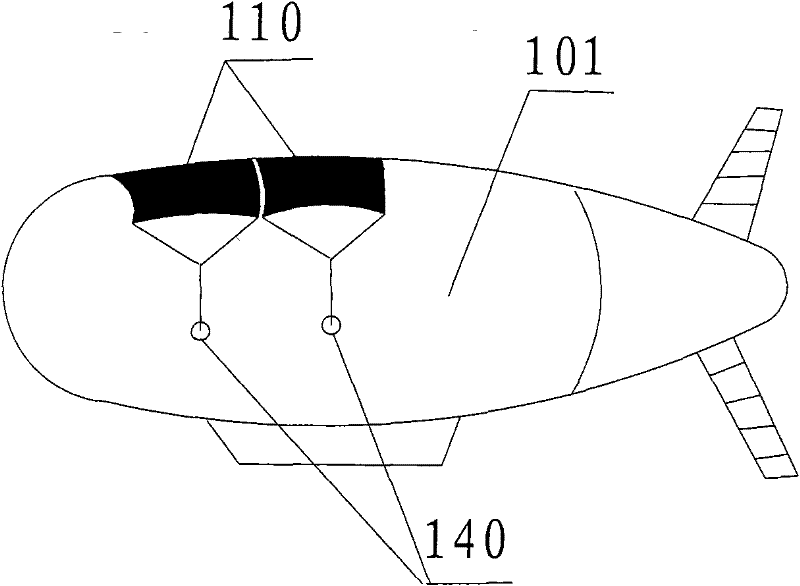

[0028] figure 1 The structure of the battery array made of ultra-light and flexible solar battery array in the present invention is given. The flexible solar battery array module 110 is assembled on the stratospheric boat skin 101 through the hanging rope 140 to form the battery array, so as to make full use of the abundant solar energy and convert it converted into current.

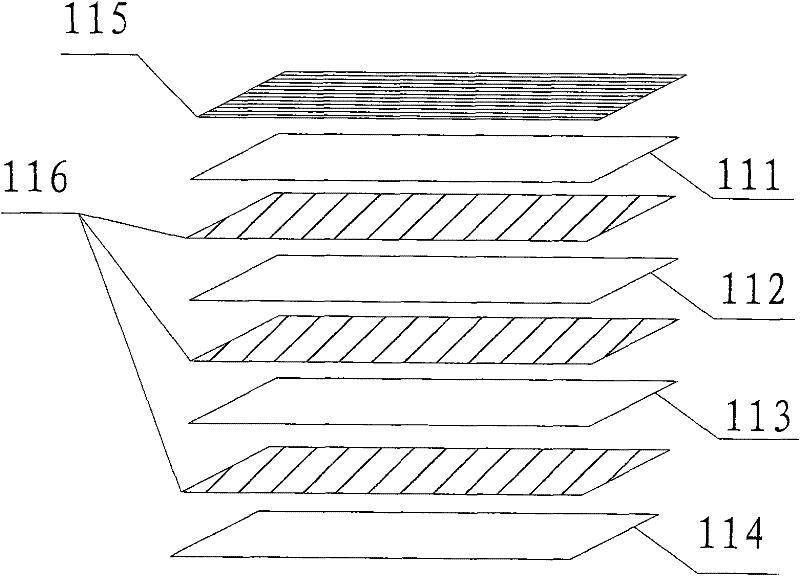

[0029] figure 2 The ultra-light and flexible solar cell module structure is given. The flexible thin-film solar cell 111 and the substrate layer 112 are combined through the adhesive layer 116, which plays the role of cell positioning and back insulation; the substrate layer 112 and the reinforcement layer 113 are bonded through the adhesive The combination of the bonding layer 116 plays the role of strengthening the strength of the battery assembly and the connection strength between the battery modules; the reinforcing layer 113 and the heat insulation layer 114 are combined through the bonding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com