Electric vehicle automatic variable speed motor

An automatic variable speed, electric vehicle technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems that affect the best performance of electric vehicle motor power, electric vehicle powerlessness, power reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

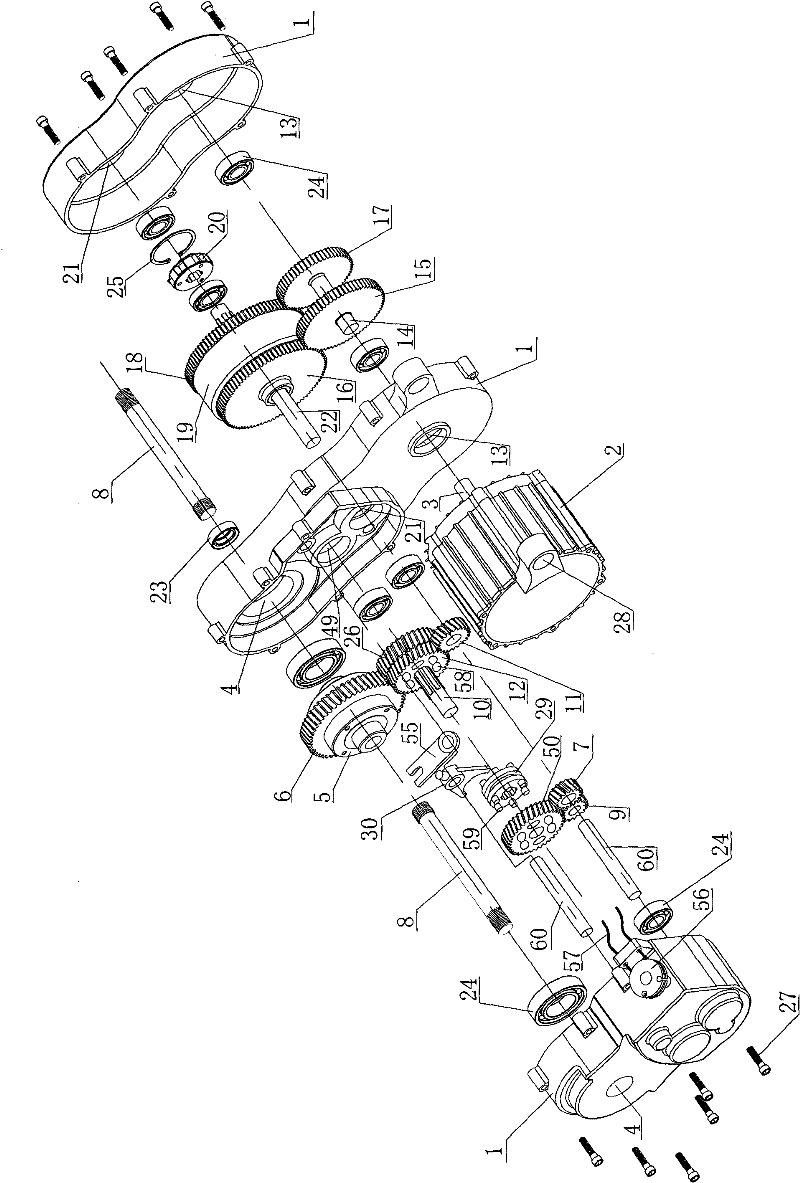

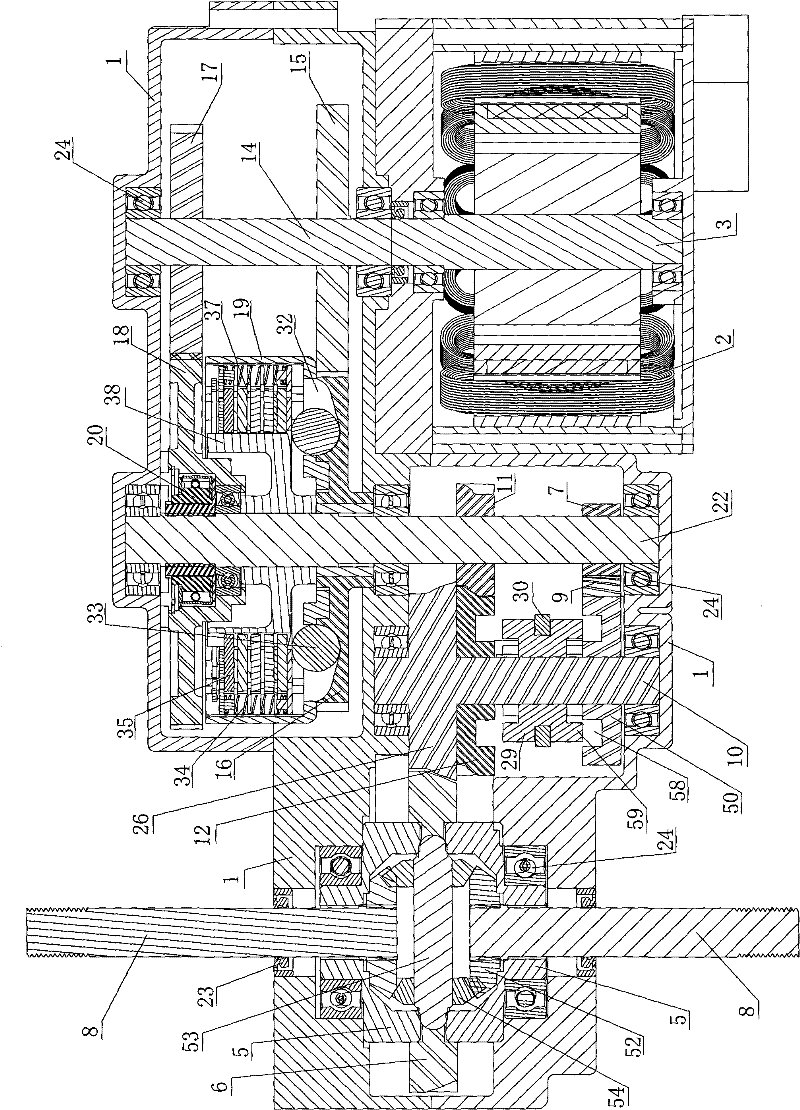

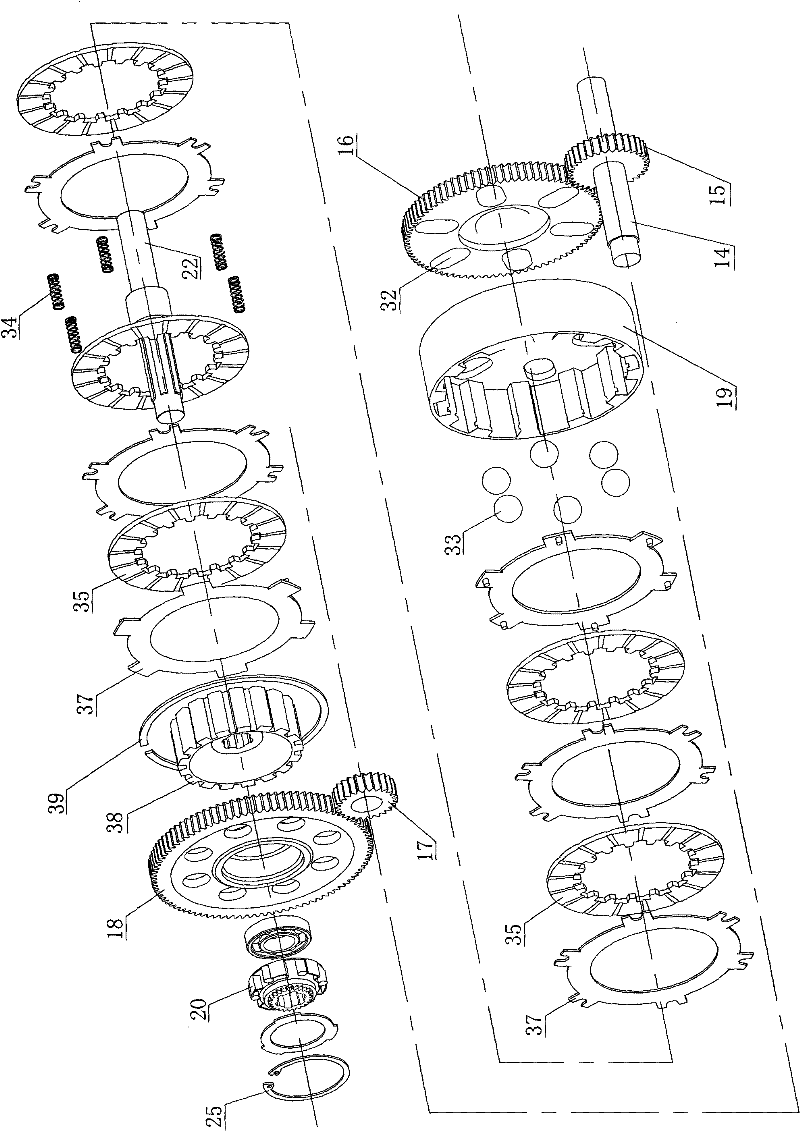

[0028] Such as Figure 1 to Figure 9 with Figure 14 , Figure 15 , 16 Shown is the first embodiment of the electric vehicle automatic transmission motor of the present invention, the electric vehicle automatic transmission motor includes a box body 1, the box body 1 is provided with a frame connection hole 28, and the vehicle frame connection hole 28 is used for Fix the whole machine on the frame. The motor 2 is fixed on the side wall of the casing 1 with bolts, and the inner side wall of the casing 1 is respectively provided with an input shaft mounting hole 13, an output shaft mounting hole 21, a wheel shaft hole 4, and an intermediate shaft hole 49. Bearings 24 are respectively provided in the bearing 24, and the inner holes of the bearings 24 are respectively provided with an input shaft 14, an output shaft 22, an intermediate shaft 10, and a differential package 5. The high and low speed driving gears are fixed on the input shaft 14, and are connected with the high an...

Embodiment 2

[0036] Such as Figure 10 , 11 , 12, 13, 14, 15, and 16 are the second embodiment of the automatic variable speed motor of the electric vehicle of the present invention, which is different from Embodiment 1 in that the output shaft 22 and the low-speed driven gear 18 do not have a one-way transmission 20, and a one-way bearing 31 is provided between the input shaft 14 and the low-speed driving gear 17. The automatic shifting motor of the electric vehicle includes a box body 1, and the box body 1 is provided with a vehicle frame connecting hole 28, and the vehicle frame connecting hole 28 is used to fix the whole machine on the vehicle frame. The motor 2 is fixed on the wall of the box body 1 side with bolts 27, and the inner side wall of the box body 1 is respectively provided with an input shaft hole 13, an output shaft mounting hole 21, a wheel shaft mounting hole 4, and an intermediate shaft hole 49. Bearings 24 are respectively arranged in the holes, and the inner holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com