Method and device for the semi-active reduction of pressure oscillations in a hydraulic system

A hydraulic system, semi-active technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system component, rolling mill control device, etc., can solve the deterioration of system performance, the no longer compact power density of the actuator, and the stability of the overall system Sexual deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

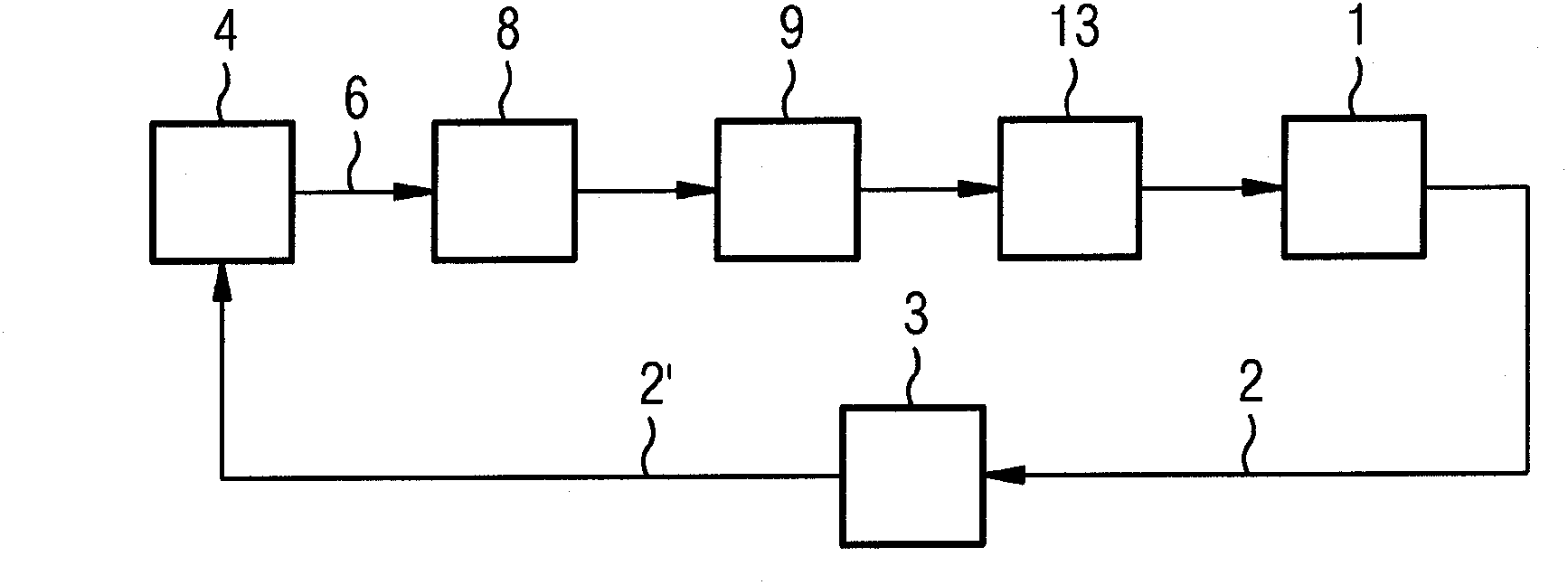

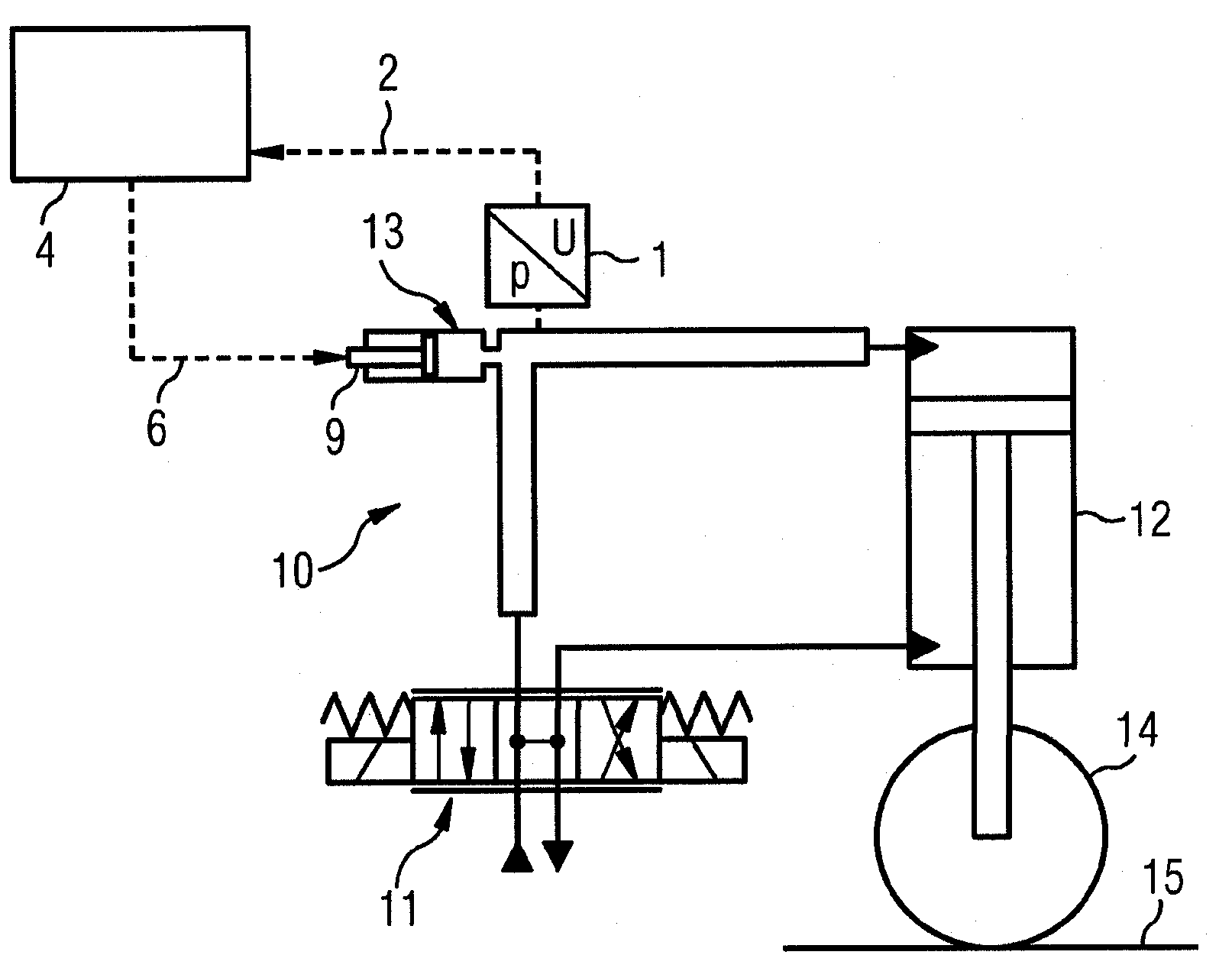

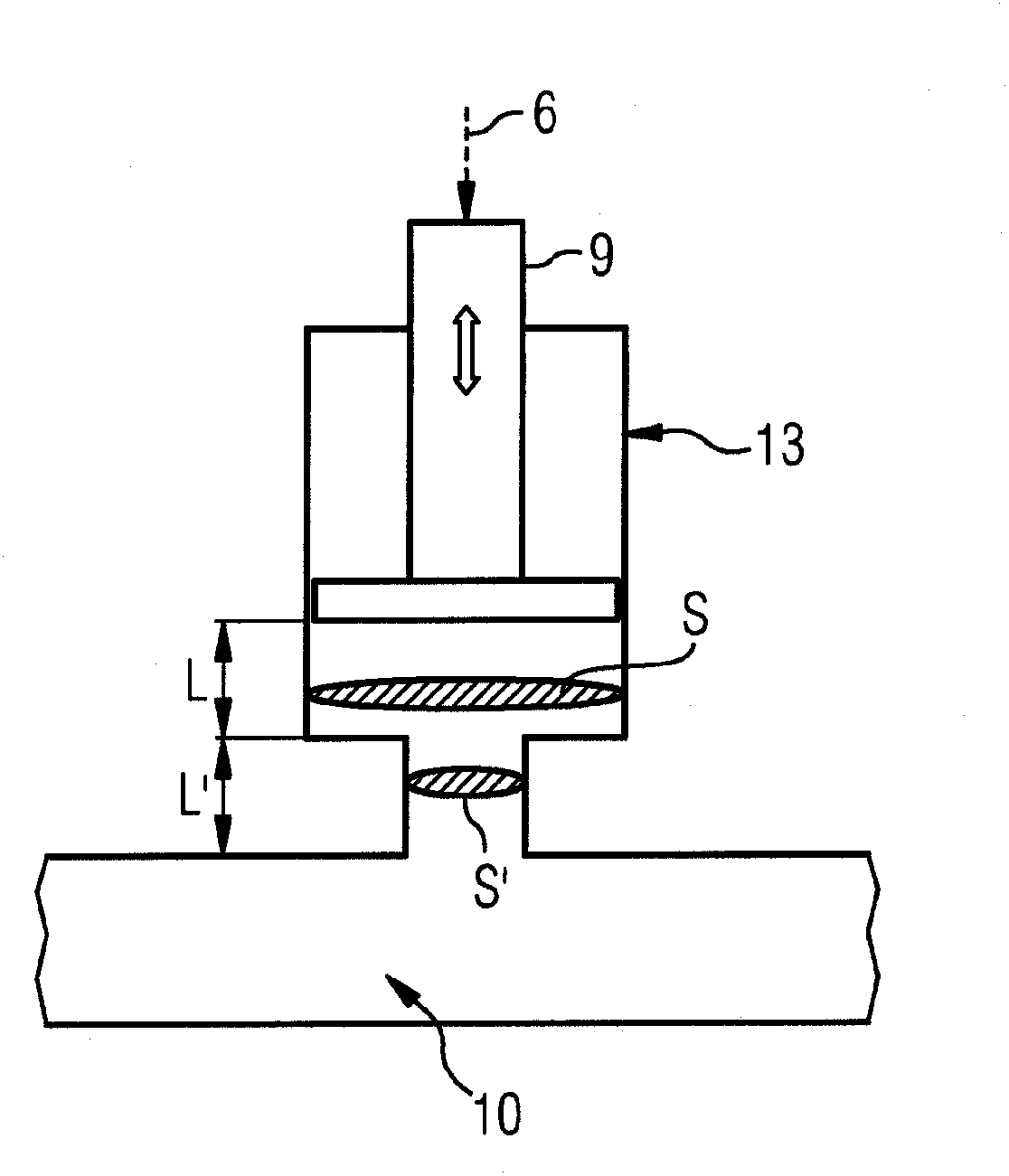

[0026] figure 1 The basic structure of the regulation path for reducing compression oscillations in the hydraulic system of a rolling mill is shown. The pressure signal of the pressure in the hydraulic system is detected by the pressure sensor 1, and the pressure signal 2 is sent to the high-pass filter 3 (for details of the electronic circuit, see, for example, page 35 of The Art of Electronics by P. Horowitz, W. Hill, Cambridge University Press, Second edition, 1989), the high-pass filter determines the AC component 2 ′ of the pressure signal 2 and supplies it to the regulator 4 . The controller 4 calculates a time-varying manipulated variable 6 in real time by means of a control law, taking into account the AC component 2 ′. The manipulated variable signal is then fed to an amplifier 8 , which activates an actuator 9 designed as an electric screw actuator. The resonator volume of the shock absorber 13 designed as a Helmholtz resonator is varied by the actuator 9 , wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com