Photovoltaic cell assembly and method of forming

A photovoltaic cell and module technology, applied in photovoltaic power generation, chemical instruments and methods, electrical components, etc., can solve the problems of prolonged processing time, increased cost, and increased cost of final buyers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

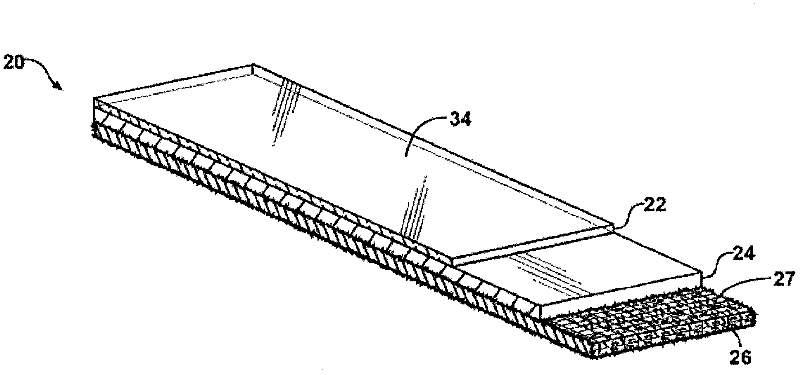

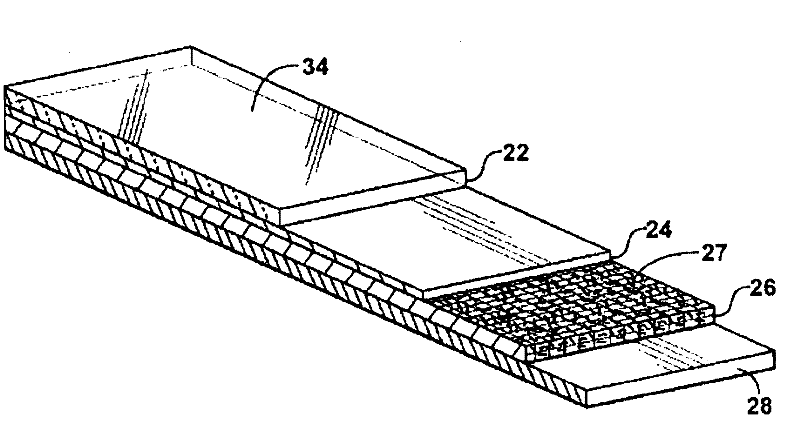

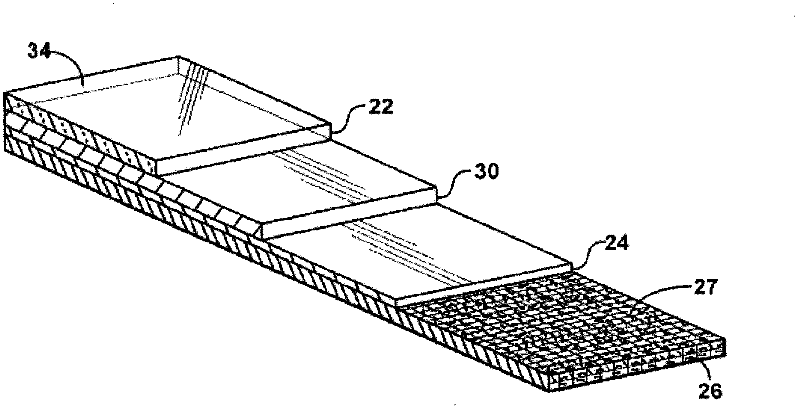

[0201] component formation

[0202] Two assemblies (assemblies A and B) were formed according to the method of the invention. In addition, four comparison assemblies (comparison assemblies A-D) not according to the method of the present invention were also formed. In modules A and B, a plurality of fibers extend laterally through the second layer to the outer edge of the module on both ends of the module.

[0203] More precisely, component A includes:

[0204]A first outermost layer (glass) of 156mmx156mmx3.2mm having a light transmittance of at least 70% as determined using the UV / Vis spectrophotometric method of ASTM E424-71;

[0205] A 156mmx156mmx200μm photovoltaic cell on the first outermost layer;

[0206] A is not uniformly distributed over and through the photovoltaic cell and includes a 5-mil second 5-mil second as a fabric (non-woven glass cloth) of a plurality of fibers at least partially coated with the first liquid silicone composition. layers; and

[0207] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com