Separator comprising porous coating and electrochemical device comprising same

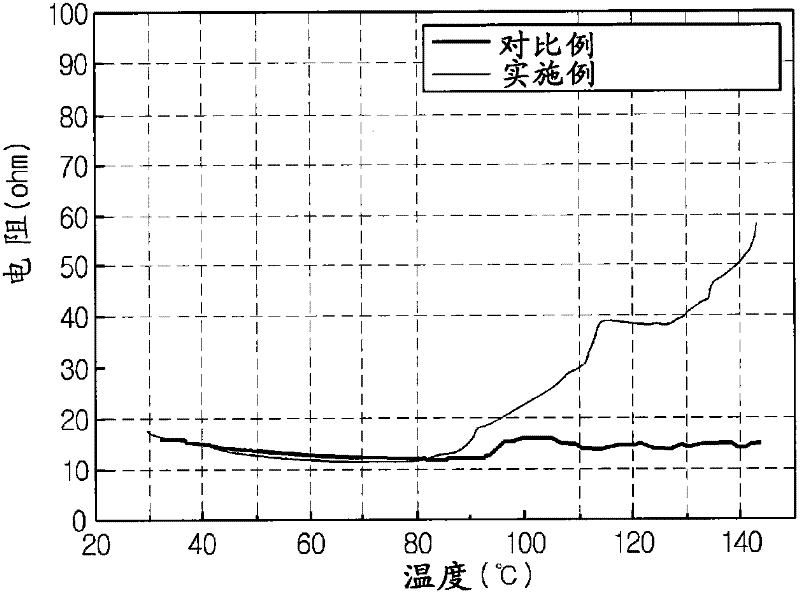

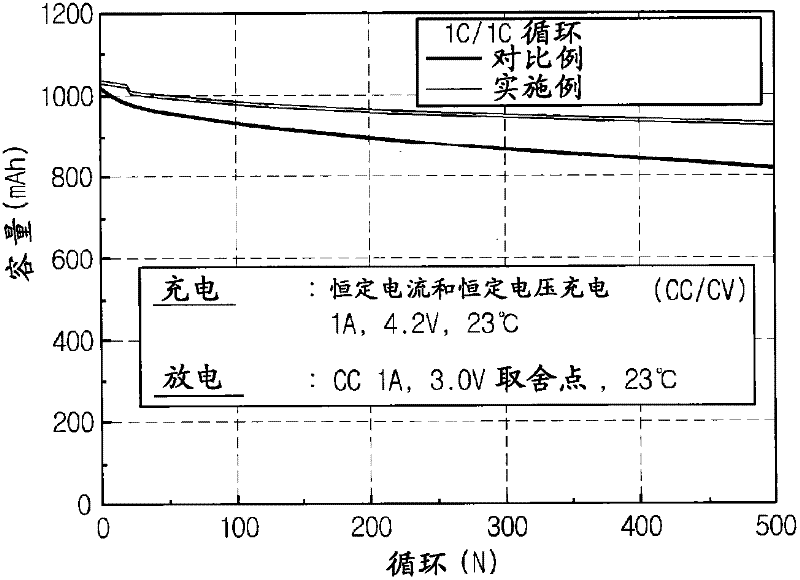

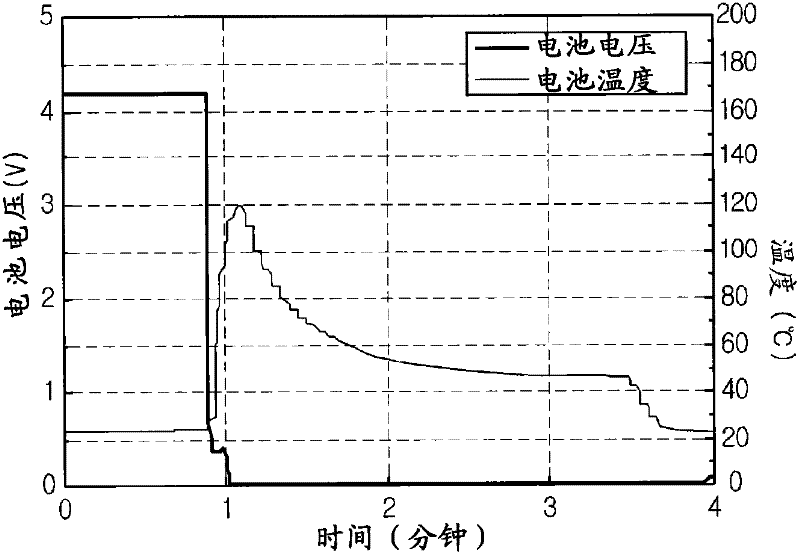

A technology of porous coating and separator, which is applied in the field of separators including porous coatings and electrochemical devices including the separators, can solve the problems of difficulty in manufacturing high-capacity batteries, increase in thickness of separators, etc., and achieves improved stability, inhibition of Short-circuit and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Diaphragm production

[0061] To acetone was added polyvinylidene fluoride-co-chlorotrifluoroethylene (PVdF-CTFE) and cyanoethyl pullulan in a weight ratio of 10:2. The binder polymer solution was prepared by dissolving the mixture at 50° C. for at least about 12 hours.

[0062] In addition, polyethylene and carbon black particles (1:1, w / w) were homogenized to prepare conductive PTC particles having an average particle diameter of 400 nm.

[0063] The conductive PTC particles and BaTiO 3 The powders were mixed in a weight ratio of 1:9 to prepare filler particles. The filler particles are dispersed in the binder polymer solution to prepare a slurry. The weight ratio of the filler particles to the binder polymer solution was adjusted to 90:10. The slurry was dip-coated on a 12 μm thick polyethylene terephthalate nonwoven base cloth to form a porous coating. The nonwoven base fabric is composed of microfibers with an average thickness of about 3 μm and has a pore s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| solubility coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com