Method and equipment for producing longitudinal submerged arc welded pipe

A technology of straight seam submerged arc welding and production methods, which is applied in the field of production methods and production equipment of straight seam submerged arc welded pipes, can solve the problems of high price, increased pipeline investment and maintenance costs, etc., achieve high production efficiency and reduce residual internal stress , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

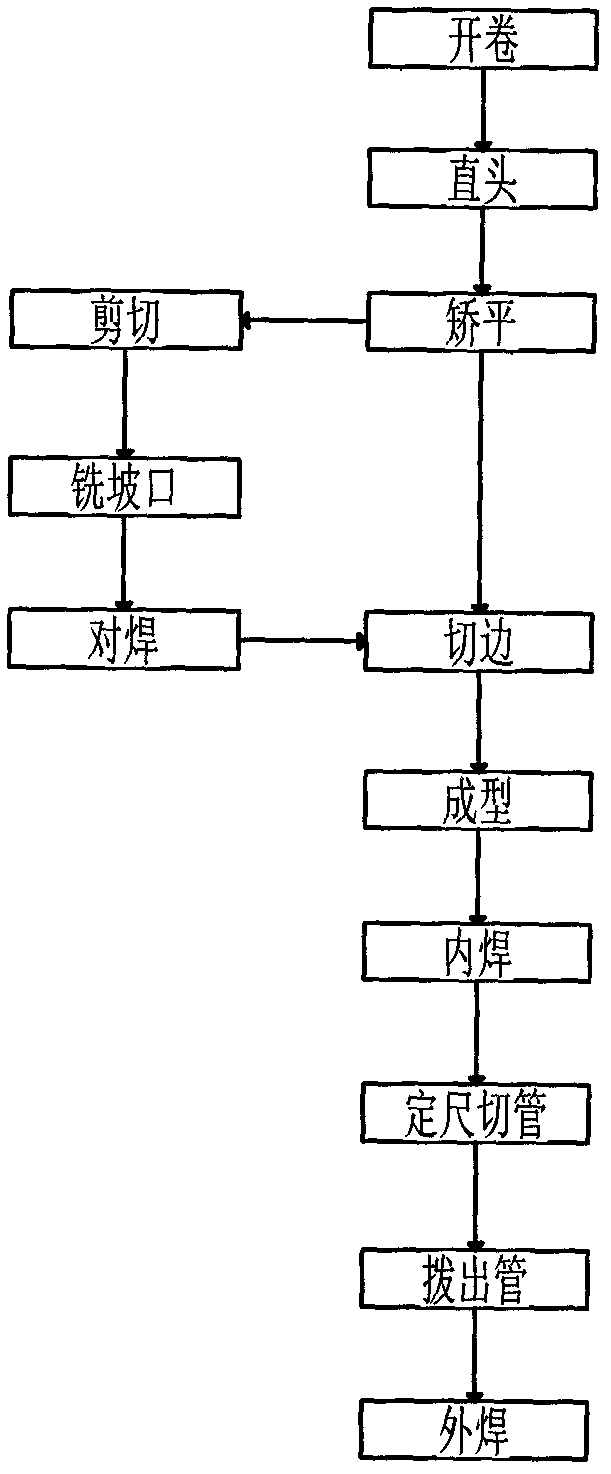

[0032] Such as figure 1 Shown, a kind of production method of straight seam submerged arc welded pipe comprises: steel coil uncoiling, straightening, leveling, trimming, forming, internal welding, cut-to-length pipe, drawing out pipe and external welding. The present invention adopts continuous The feeding method, the continuous feeding process is that the steps of coil uncoiling, straightening and leveling are placed on a trolley that can advance with the speed of the steel coil, and shearing, bevel milling and butt welding are added on the trolley craft.

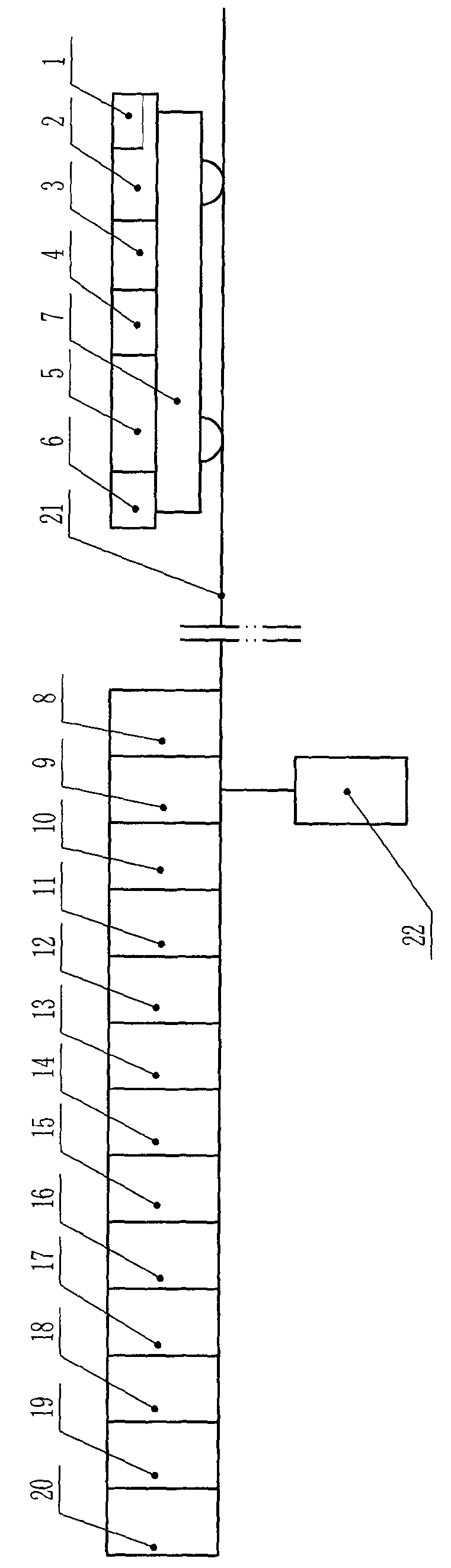

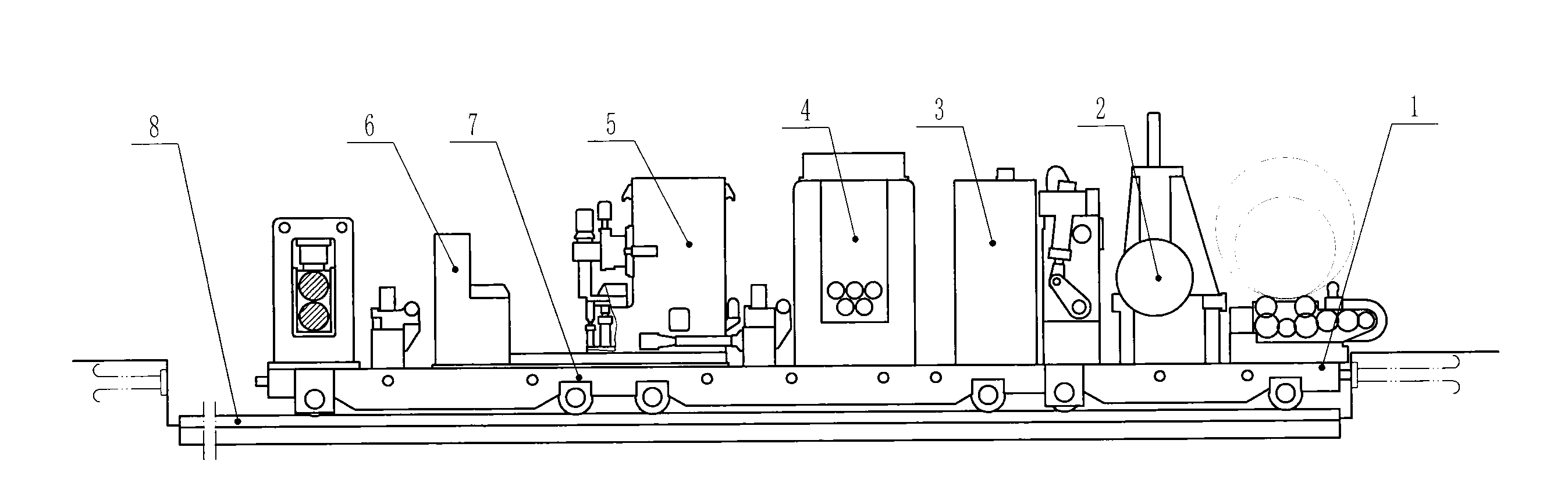

[0033] Such as figure 2 , image 3As shown, a continuous forming longitudinal submerged arc welded pipe production equipment, its structure is: uncoiler 2, head straightening machine 3, leveling roller 4, shear milling groove butt welding machine 5, pinch roller 6 press Installed on the flying welding car 7 in sequence, the flying welding car 7 is installed on the guide rail 21, the coiling car 1 is installed on the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com