A kind of sound-absorbing composite structure material and its preparation method

A composite structure and composite material technology, applied in the field of sound-absorbing materials, can solve problems such as poor sound-absorbing performance, and achieve the effect of broadening the frequency range of sound-absorbing action and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A sound-absorbing composite structural material, the components include: a perforated plate and CPE / SHSF (mass percentage is 4:1); the preparation steps of the above-mentioned sound-absorbing composite structural material are as follows:

[0043] The first step of composite material preparation:

[0044] 1) Raise the temperature of the rollers on the double-roller plastic refining machine to 65°C and keep the matrix stable; add CPE, and mix the CPE into sheets through the surface temperature of the rollers and the shear force formed between the rollers. Viscous fluid state; add SHPF, use a cutter as an auxiliary mixing tool to make the components evenly mixed, the total mixing time is 45 minutes, and peel off from the roller for hot press vulcanization;

[0045] 2) Spread the cooled mixed film evenly in the inner cavity of the mold, clamp the mold with steel plates up and down, and use a layer of high-temperature anti-adhesive film between the steel plate and the mold; ...

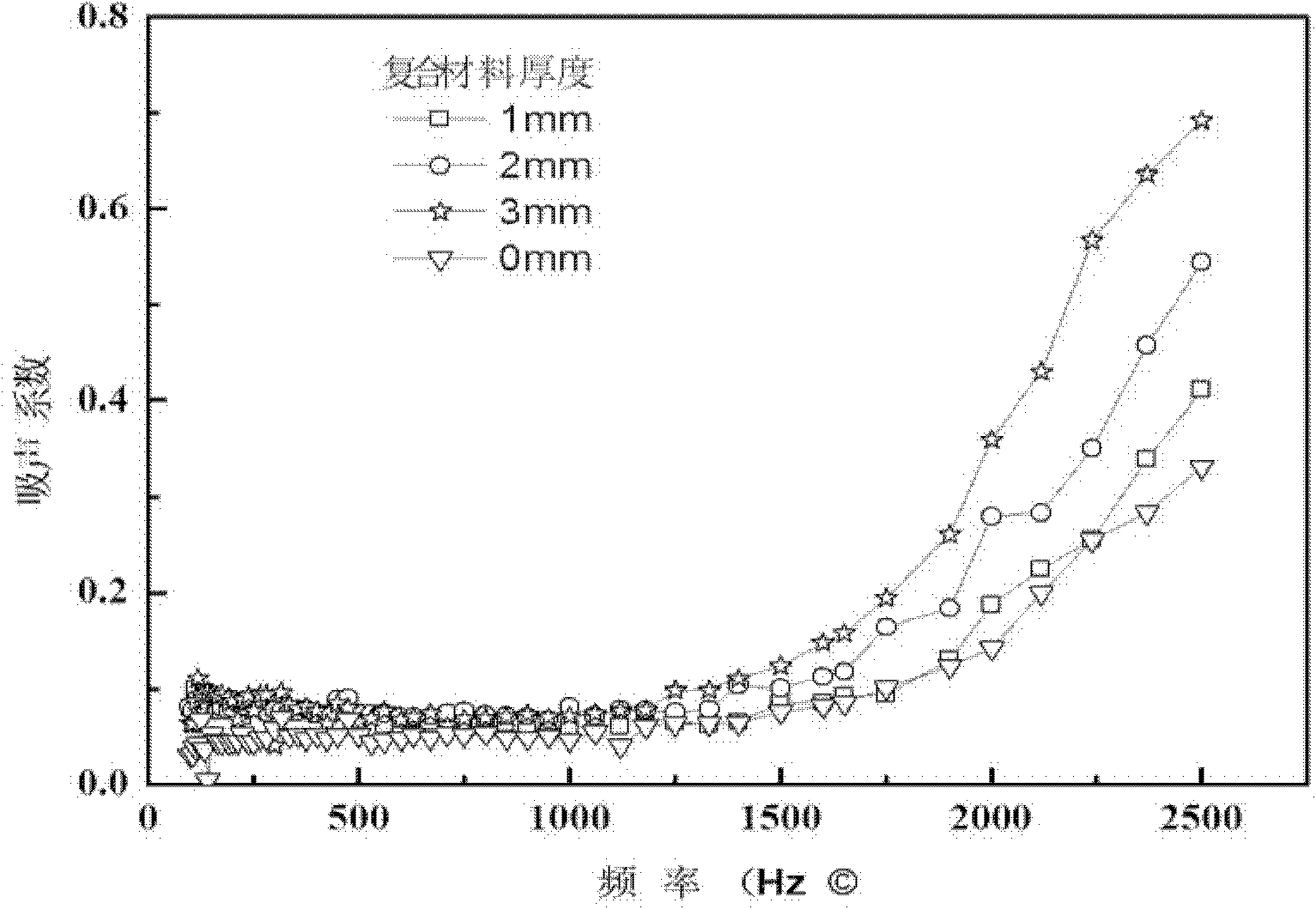

Embodiment 2

[0051] A sound-absorbing composite structural material, the components include: a perforated plate and CPE / SHSF (mass percentage is 4:1);

[0052] The preparation steps of the composite structural material are the same as in Example 1, except that the thickness of the perforated plate is 1.5 mm, the hole diameter is 5 mm, and the porosity is 60%; the test surface is not a perforated plate but a film.

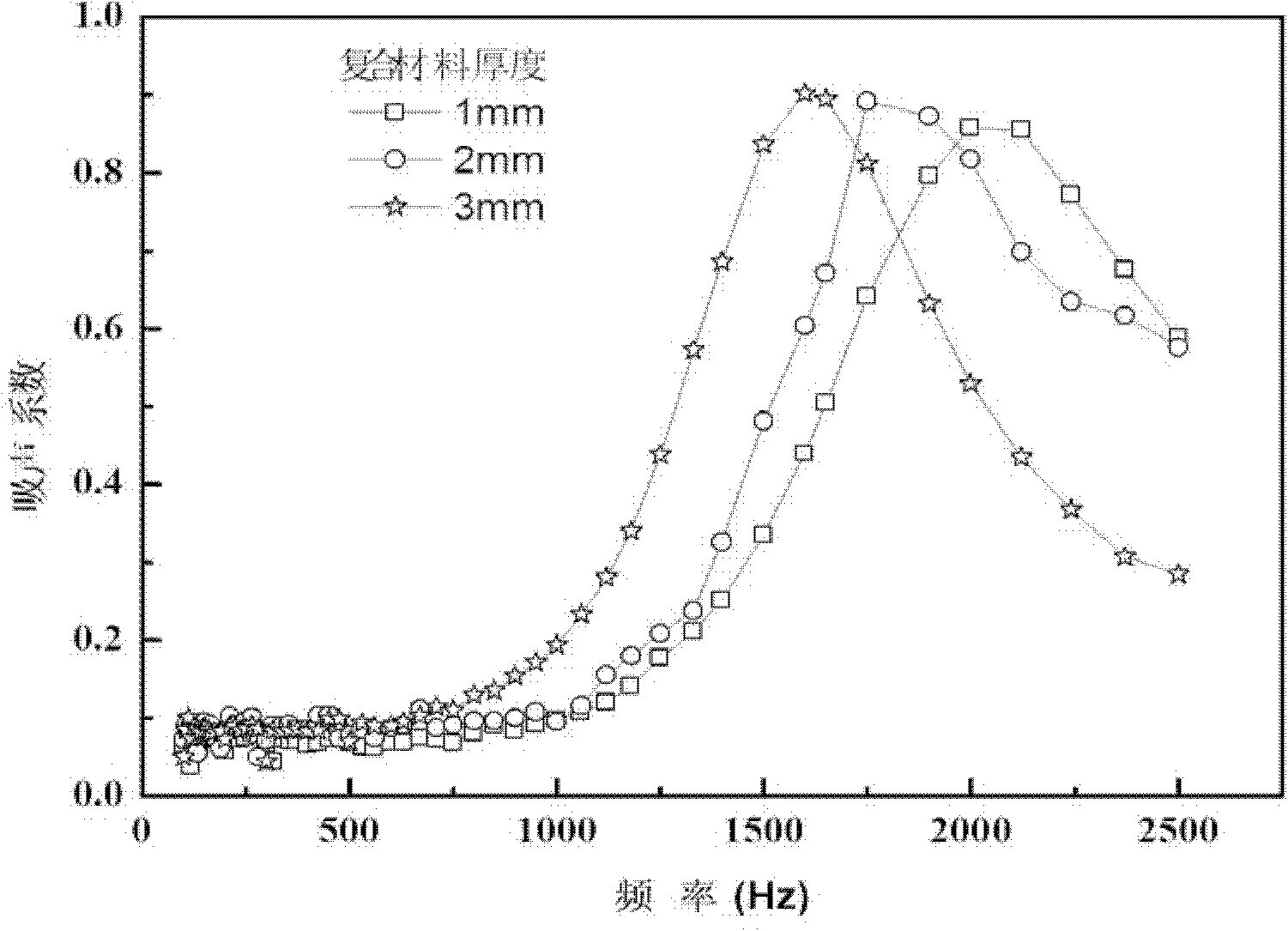

Embodiment 3

[0054] A sound-absorbing composite structural material, the components include: a perforated plate and CPE / SHSF (mass percentage is 4:1);

[0055] The preparation steps of the composite structural material are the same as those in Example 1, except that the process of gluing changes from two layers to four layers. The specific combination is perforated plate (thickness 1.5mm, aperture 5mm porosity 50%) / composite material (thickness 2mm) / perforated plate (thickness 1.5mm, aperture 5mm porosity 40%) / composite material (thickness 1mm); perforated plate ( Thickness 1.5mm, aperture 5mm porosity 50%) / composite material (thickness 1mm) / perforated plate (thickness 1.5mm, aperture 5mm porosity 40%) / composite material (thickness 2mm); perforated plate (thickness 2mm, aperture 5mm porosity rate 60%) / composite material (thickness 3mm) / perforated plate (thickness 1.5mm, aperture 5mm porosity 60%) / composite material (thickness 2mm) in total three different combinations. (The test surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com