Polyurethane-containing low-density high-pressure polyethylene protective film and preparation method thereof

A high-pressure polyethylene, low-density technology, applied in the direction of polyurea/polyurethane adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of increasing cost input and reducing production efficiency, and achieve Inexpensive, good elongation, and good extrudability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

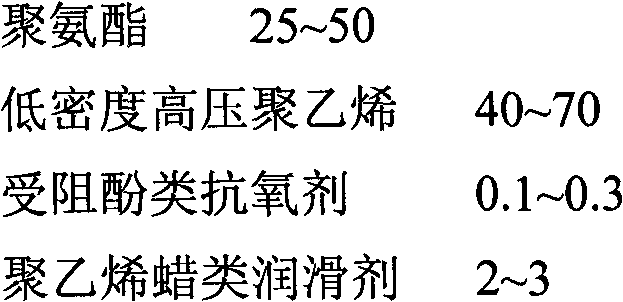

[0025] Embodiment 1: the low-density high-pressure polyethylene protective film containing polyurethane comprises the following components and weight ratio: polyurethane 35, low-density high-pressure polyethylene 47.3, Irganox 1010 0.2, PE-520 wax powder 2.5, polyethylene grafted Malay Anhydride 15.

[0026] The preparation method of protective film, comprises the steps:

[0027] ①Add each component into the mixer and stir, the stirring speed is 110U / min~130U / min, and the stirring time is 4~8 minutes;

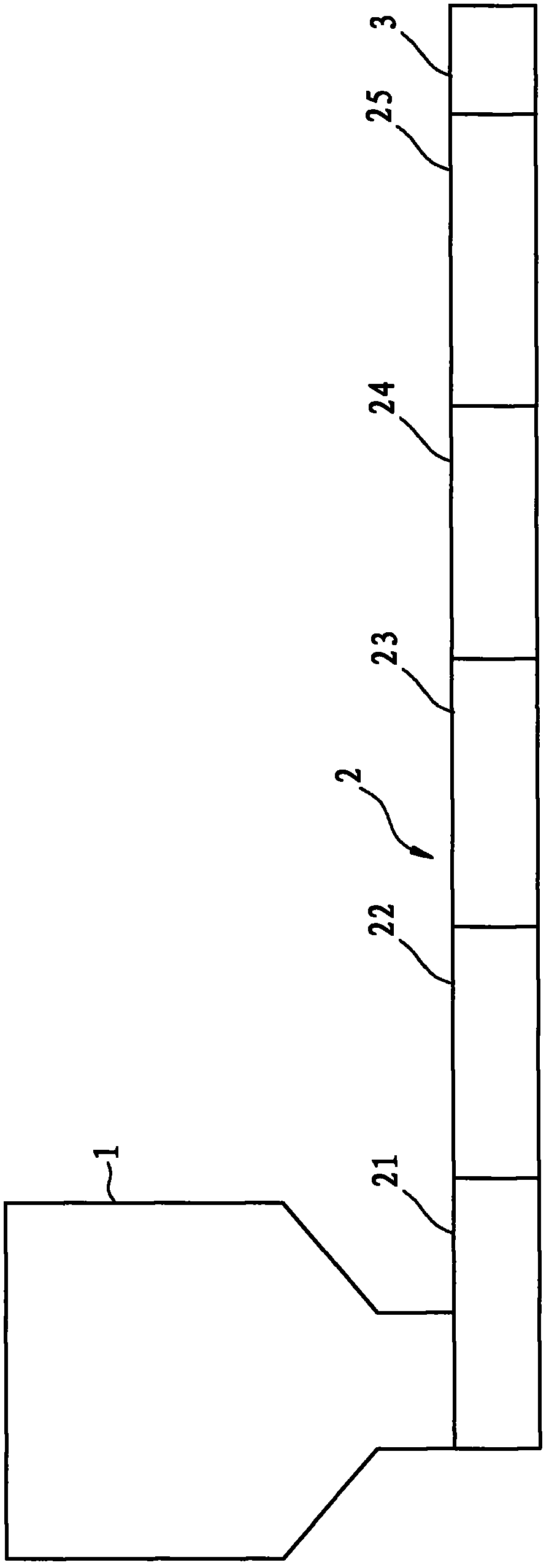

[0028] ② Put the stirred material into the barrel 1 of the twin-screw extruder and extrude it through the extrusion channel 2 and the head 3 in sequence. The extrusion channel of the extruder is divided into five areas, area 1 21, area 2 The temperature control conditions for zone two 22, zone three 23, zone four 24 and zone five 25 are 160°C to 170°C, 170°C to 180°C, 180°C to 190°C, 190°C to 200°C, 195°C to 205°C, and The temperature control condition of extruder head 3 is 1...

Embodiment 2

[0030] Embodiment 2: The low-density high-pressure polyethylene protective film containing polyurethane comprises the following components and weight ratio: polyurethane 25, low-density high-pressure polyethylene 65, antioxidant AT-300 0.1, PE-520 wax powder 3, polyethylene Grafted maleic anhydride 20. The preparation method refers to Example 1.

Embodiment 3

[0031] Example 3: The low-density high-pressure polyethylene protective film containing polyurethane includes the following components and weight ratio: polyurethane 40, low-density high-pressure polyethylene 40, antioxidant 1076 0.3, polyethylene wax CH-2A 2, acrylic acid 10. The preparation method refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com