Standard steel frame formwork system for concrete floor slabs and construction method thereof

A construction method and floor formwork technology, which are applied to the shaping steel frame formwork system of the frame structure concrete floor, and the field of shear walls, can solve the problems of non-compliance with energy saving, environmental protection and low cost, and achieve the safety, reliability and good applicability of the support system. , the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

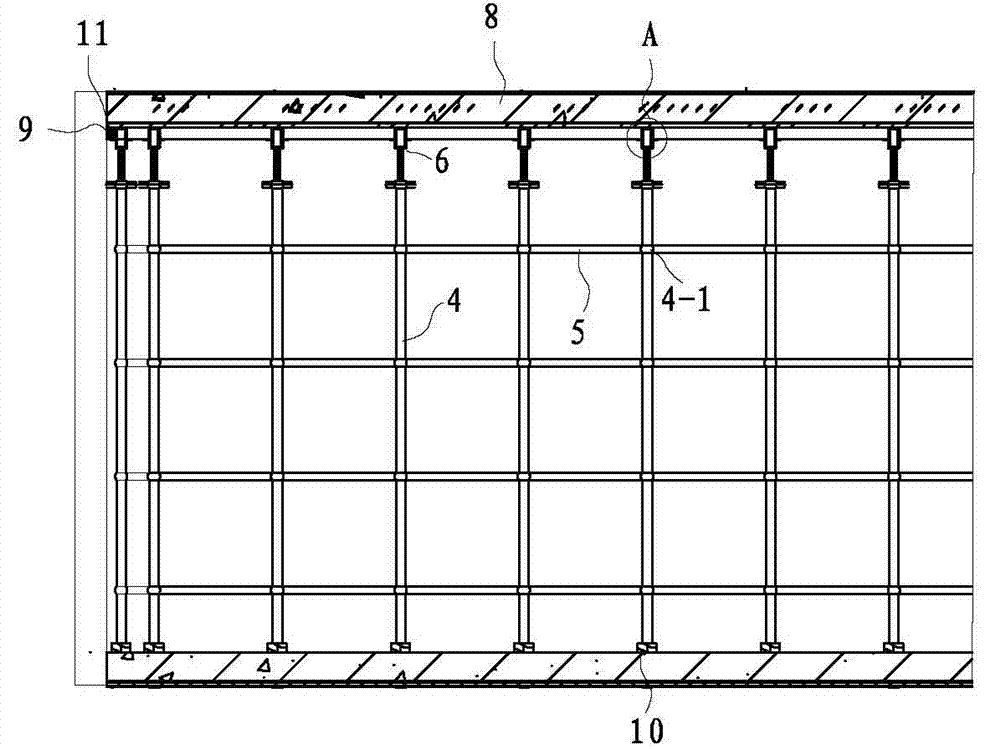

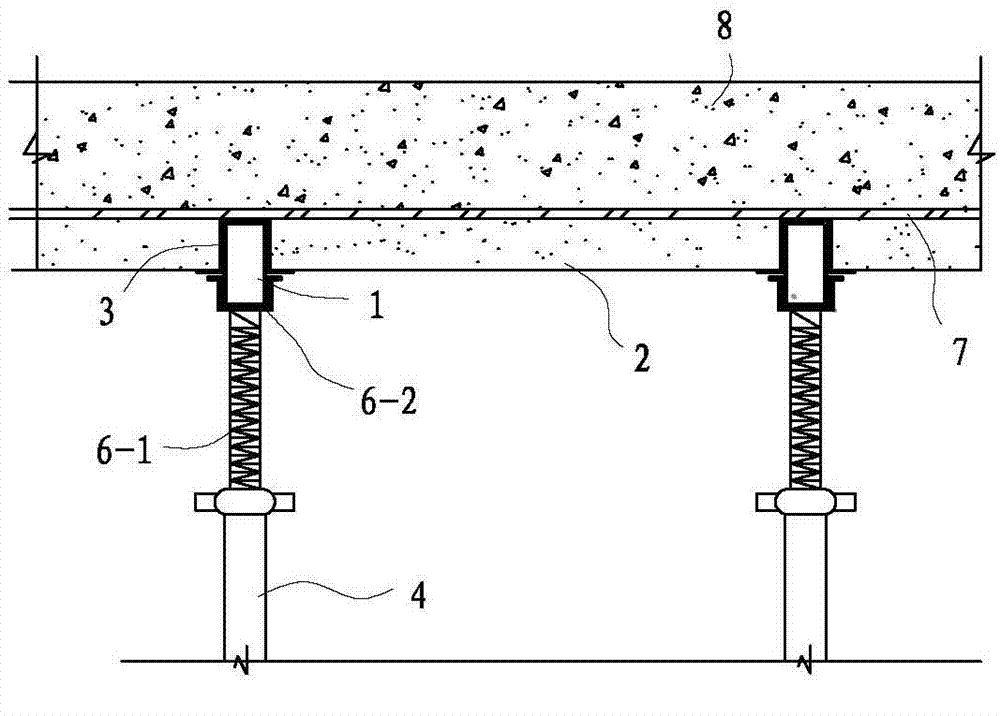

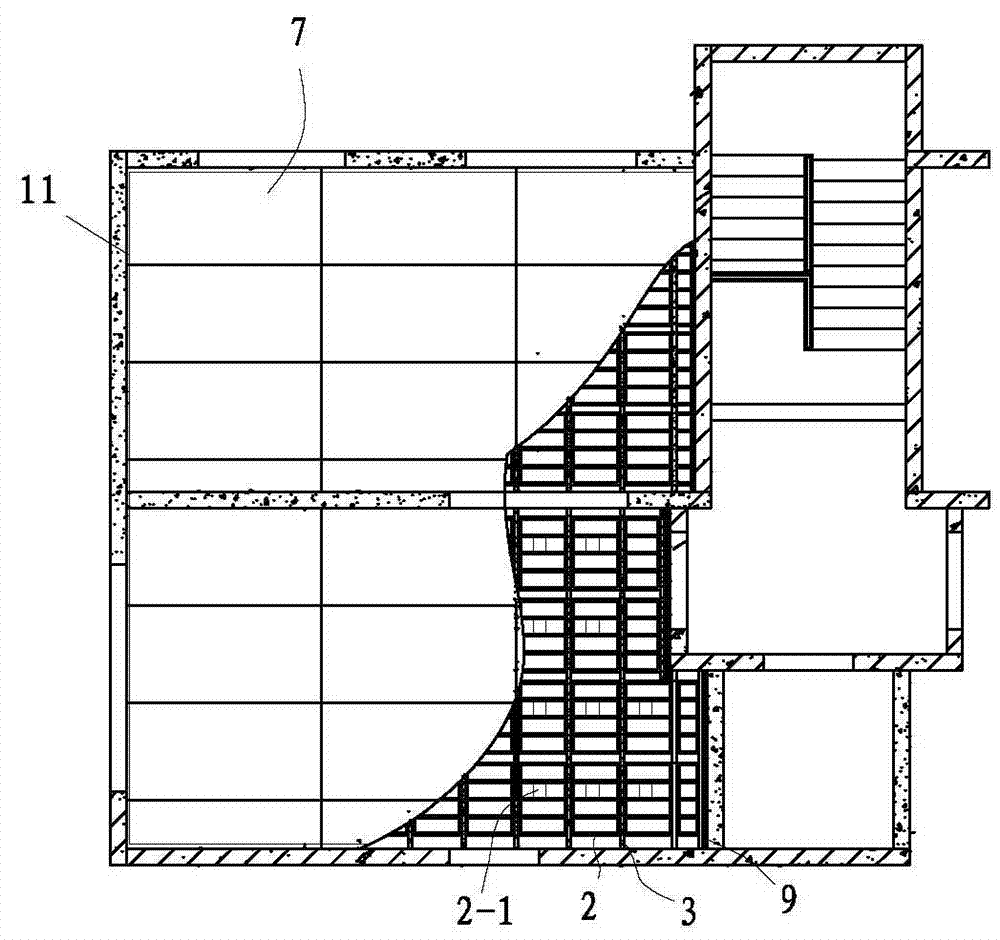

[0051] Concrete floor shaped steel frame formwork system embodiment, see Figure 1 to Figure 8 ,like Figure 1 to Figure 3 As shown, the formwork system includes a square steel beam 1, a steel frame 2 made of shaped square steel, a saddle beam 3, a vertical bar 4, and a cross bar 5 through steel plate molding; the cross bar is connected with the fastener 4-1 Adjacent poles are tied and fixed, U brackets 6 are installed on the poles, square steel beams are installed on the U brackets as the main keel, saddle beams are placed on the main keel, steel frames are placed on the saddle beams as secondary keels, and laid on the steel frame The formwork 7 is poured with a concrete floor 8 on the formwork.

[0052] The distance between the poles and the poles, when the thickness of the floor is 100 mm to 250 mm, the distance between the poles is 950 mm × 650 mm (950 mm × 650 mm is a common name in the industry, the actual length and width of the poles are 950 mm and 650 mm;) ; When th...

Embodiment 2

[0058] An embodiment of the construction method of the concrete floor shaped steel frame formwork system. The construction method is realized on the basis of Embodiment 1, and its technological process is as follows:

[0059] Elevation line of spring slab support formwork → place pole cross positioning line → install pole skid and pole → install cross bar → install U bracket → install square steel beam → install saddle beam → install shaped steel frame → pull wire leveling → full pavement Multi-layer board formwork → adjustment, arching, reinforcement → cleaning → inspection and acceptance → formwork removal;

[0060] The specific process steps are:

[0061] a. Steps to play the elevation line of the formwork support on the wall and the cross positioning line of the vertical pole:

[0062] After the wall formwork is removed, the horizontal control line that controls the formwork elevation is played on the wall, and the pole cross positioning line is placed according to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com