dual clutch gearbox

A dual-clutch and gearbox technology, applied in the direction of instruments, controlled components, mechanical control devices, etc., can solve the problems of reduced service life of low-gear gears, damage of low-gear gears, and long power transmission routes, so as to improve the use of Effects of life, short transmission route, and reduced damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

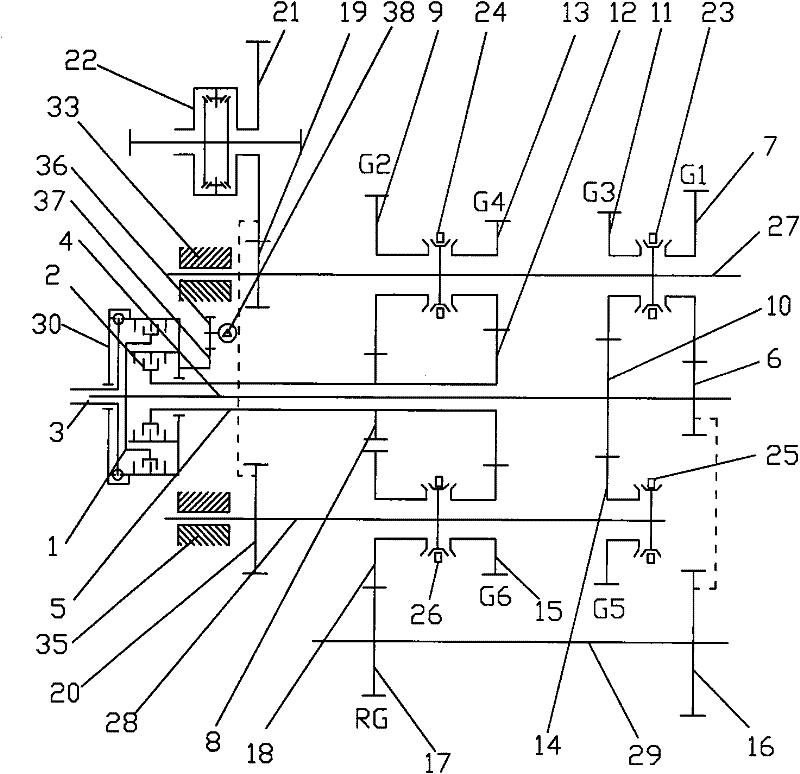

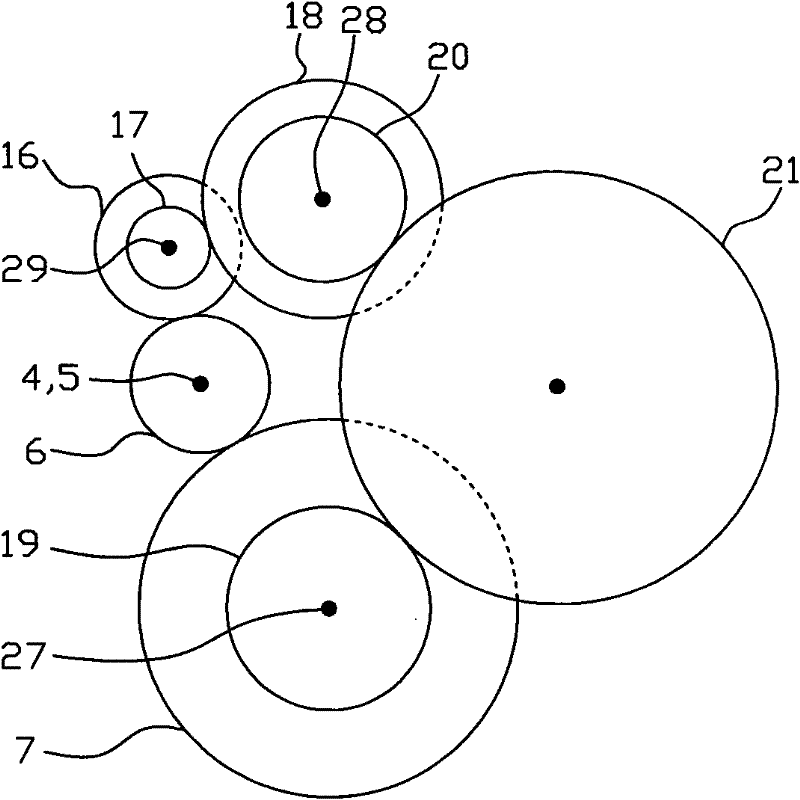

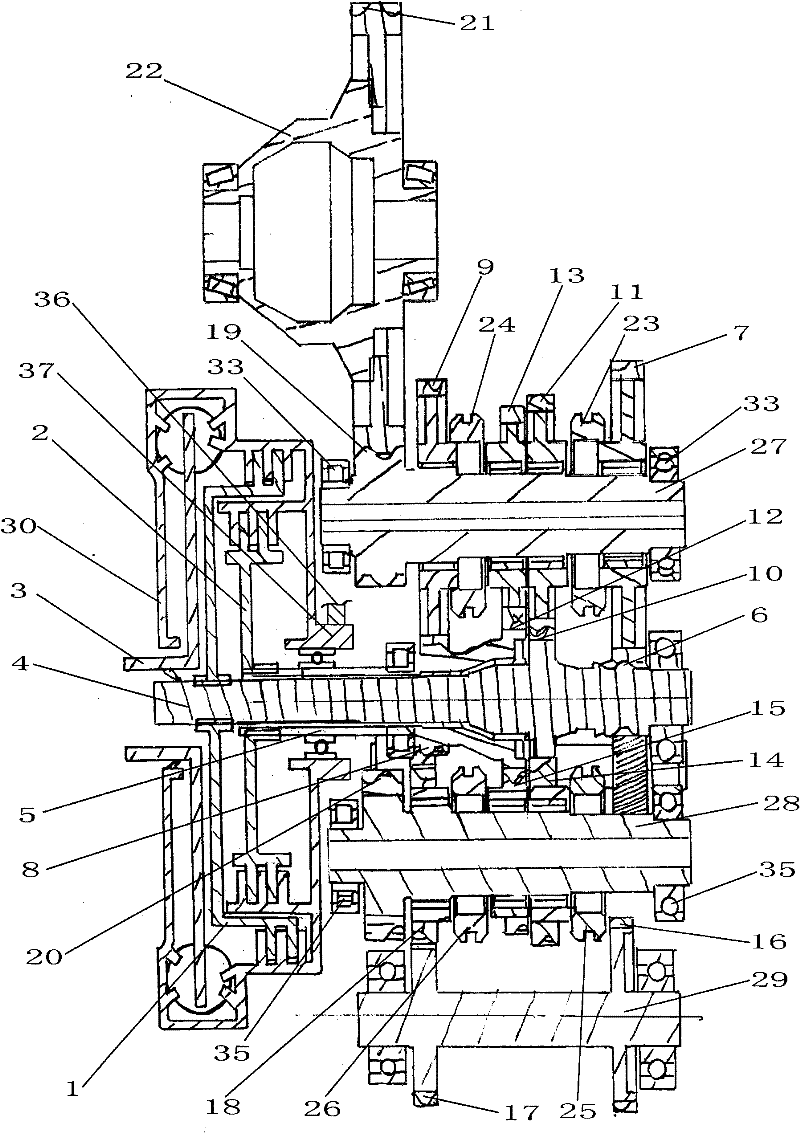

[0036] Such as figure 1 , image 3 As shown, the dual clutch gearbox of the present invention has two coaxially arranged input shafts 4 and 5 respectively connected to two clutches 1, 2 and the output shaft of the engine is connected to the clutch driving shaft 3. The torque of the engine It can be selectively transmitted to the inner input shaft 4 or the outer input shaft 5 through the two clutches 1 and 2. Among them, a first-speed driving gear 6 and a third-speed driving gear 10 are fixedly installed on the inner input shaft 4. The first-speed driving gear 6 is located at the rear end of the inner input shaft 4 (the end far from the engine); the outer input shaft 5 is fixedly installed with two The second-speed driving gear 8 is located at the front end of the outer input shaft 5 (close to the end of the engine), so that from the entire input shaft 4, 5, the second-speed driving gear 8 and the first The gear driving gear 6 is located on the front and rear sides, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com