Joint measurement method of impurity elements in silver

An impurity element, silver technology, applied in the preparation of test samples, material excitation analysis, thermal excitation analysis, etc., can solve the problems of low results and long analysis time, and achieve the effect of shortening time and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

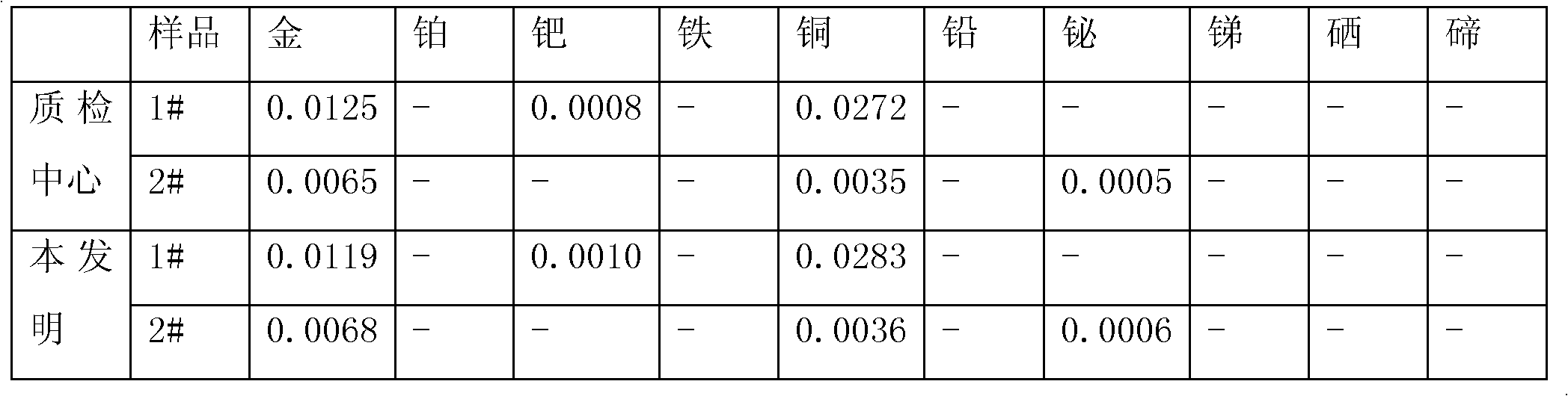

Examples

Embodiment 1

[0030] A joint measurement method for impurity elements in silver, comprising the following steps:

[0031] The first step: sample processing, use a flaking machine to crush high-grade silver into thin slices of about 0.2mm, first treat the sample with 0.9% hydrochloric acid, wash it with distilled water, wipe the sample with alcohol, and dry it for later use.

[0032] Step 2: Weigh 1 gram of sample and add 0.5 ml of sodium citrate complexing agent and 10 ml of 1:1 nitric acid to dissolve the sample in a beaker.

[0033] Step 3: When the reaction is complete, add 1ml of saturated sodium chloride solution, heat and boil to clarify the solution, and pour it out into the funnel for filtration by decanting.

[0034] Step 4: Add 15ml of aqua regia and 1ml of saturated sodium citrate complexing agent to the silver chloride precipitate in the beaker, heat to boil for 20min, and then use the method in the previous step to filter.

[0035] The fifth step is to add 10ml of aqua regia a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com