A method for preparing adsorbent from residue after lignite extraction of humic acid

A humic acid and adsorbent technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of large amount of alkali, high cost and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

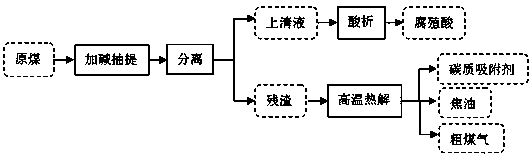

Method used

Image

Examples

Embodiment 1

[0022] Humic acid extraction:

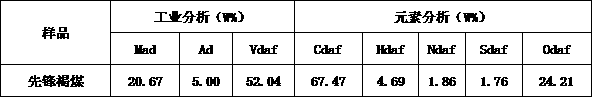

[0023] Air-dried Pioneer lignite is used as raw material, pulverized by a coal mill, impurities are removed, sieved, and the 40-mesh undersize (coal powder) is sealed and collected. Table 1 shows the composition analysis of Pioneer lignite.

[0024] Table 1 Industrial analysis and elemental analysis of Xianfeng lignite

[0025]

[0026] Weigh 5 parts of 5g coal samples into a three-neck flask, add 150mL of NaOH solution with a mass percentage concentration of 2%, 3%, 4%, 5%, and 6% respectively, and store them at 90°C, 80°C, 70°C, Heating in water bath at 60°C and 50°C for 3h, 2.5h, 2h, 1h, 0.5h. The reacted solution is cooled and then centrifuged, and the supernatant liquid is evaporated to remove water, which is humic acid salt. The yields of humate at different alkali extraction concentrations are shown in Table 2. It can be seen that the yield of humate obtained when the NaOH concentration is 4% is the highest.

[0027] Table 2 Humat...

Embodiment 2

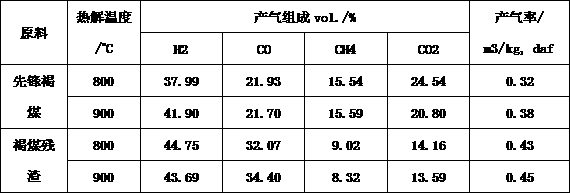

[0031] Pyrolysis:

[0032] Weigh 5g of 40-80 mesh air-dried pioneer lignite, and heat it in a water bath at 80°C for 1h in 150mL NaOH solution with a concentration of 4%. The solution after the reaction is cooled and centrifuged, and the precipitate is put into an oven for 105 o C dried for 2h. Take 3g of dry lignite residue and put it into the pyrolysis reaction tube, pass nitrogen as protective gas, and set the temperature rise rate of the temperature controller to be 10 o C / min, respectively at 760 o C and 940 oC pyrolysis at the end temperature of pyrolysis (also known as pyrolysis temperature in the examples), and the constant temperature time is 30 min. The pyrolyzed solid product is washed with deionized water to neutrality, and dried at high temperature to constant weight to finally obtain the carbonaceous adsorbent.

[0033] It has been verified by actual experiments that the dry lignite residue can be heated and pyrolyzed in the pyrolysis furnace under the prote...

Embodiment 3

[0042] Weigh 5g of air-dried vanguard lignite below 80 meshes, and add concentrations of 2%, 3%, 4%, and 5% respectively in 300mL NaOH solution, o C for 20 min in an ultrasonic water bath. The solution after the reaction is cooled and centrifuged, and the precipitate is put into an oven for 105 o C dried for 2 h. Take 3g of dry lignite residue and put it into the pyrolysis reaction tube, pass nitrogen as protective gas, and set the temperature rise rate of the temperature controller to be 10 o C / min at 900 o C pyrolysis temperature pyrolysis, constant temperature time is 20 min. Table 5 shows the iodine value, specific surface area, pore volume and average pore diameter of lignite residue pyrolysis coke after humic acid extraction with different alkali concentrations.

[0043] Table 5 Iodine value and pore structure parameters of residue pyrolysis coke after lignite humic acid extraction with different alkali concentrations

[0044] NaOH concentration / % Iodine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com