Fluorescent material used for PDP and preparation method thereof

A technology of fluorescent materials and various elements, which is applied in the field of fluorescent materials for ion display PDP and its preparation, can solve the problems that the particle size distribution of precursors is not concentrated enough, affects the shape of PDP fluorescent materials and the concentration of particle size distribution, and achieves experimental methods. Ease of operation, consistent precipitation conditions, and small particle size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

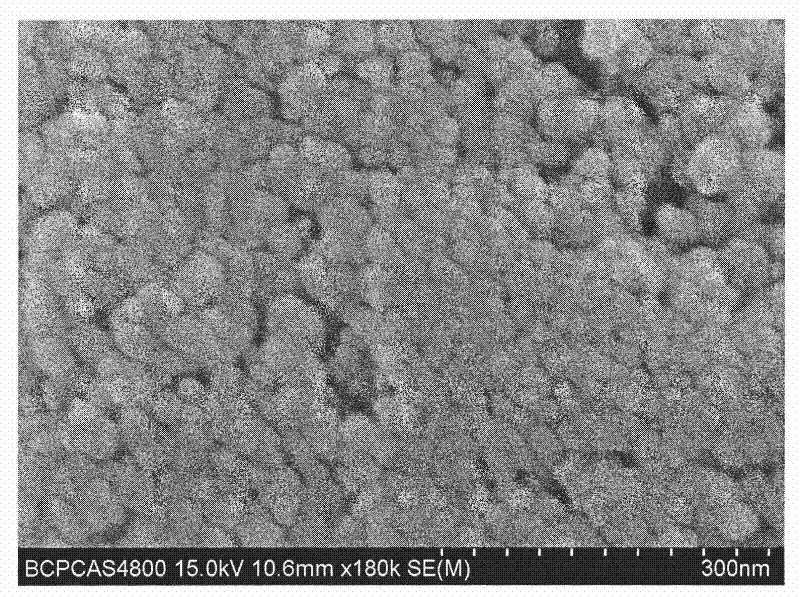

[0034] According to Ba 0.95 Al 12 o 19 : 0.05Mn weighed BaCO 3 1.87g was dissolved in dilute nitric acid to obtain a 0.1Mol / L homogeneous solution, Al(NO 3 ) 3 9H 2 O 45.02g and MnCl 2 4(H 2 O) 0.10g is dissolved in deionized water and added to the above 0.1Mol / L Ba 2+ In the solution, after stirring to obtain a homogeneous solution concentration of 0.1Mol / L, measure urea (with a metal ion molar ratio of 10:1) and dissolve it in deionized water to make a 1.0Mol / L urea solution and add it to the above-mentioned homogeneous solution. Then add 90% ammonium sulfate [(NH 4 ) 2 SO 4 ] (ratio to the amount of metal ion substance is 1:10) is used as a dispersant, and the above mixed solution is fully stirred to obtain a homogeneous solution. The homogeneous solution was heated in a water bath set at 95° C. and stirred continuously with a magnetic stirrer. After 3.5 hours, a white colloid was obtained. Above-mentioned colloid is carried out suction filtration, the suction f...

Embodiment 2

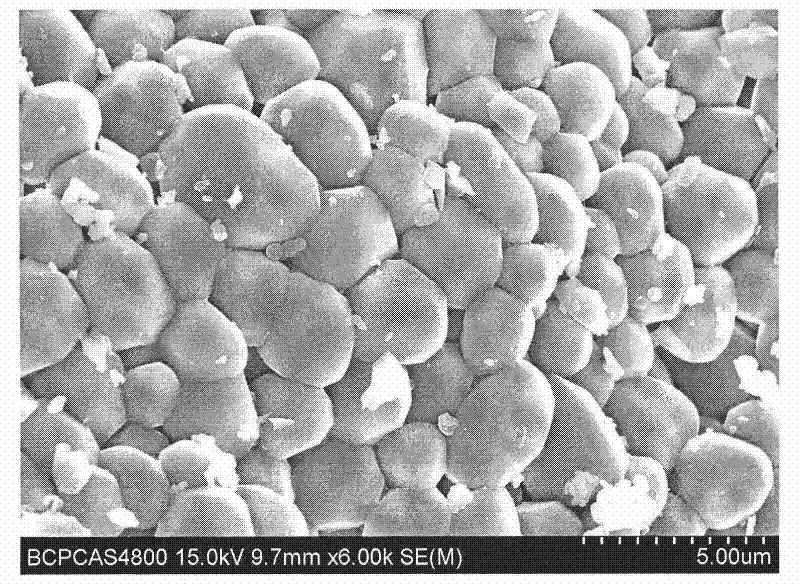

[0036] According to Ba 0.8 Al 12 o 19 : 0.2Eu weighed and weighed BaCO 3 1.57g was dissolved in dilute nitric acid to obtain a homogeneous solution of 0.7Mol / L, Al(NO 3 ) 3 9H 2 O 45.02g and Eu(NO 3 ) 3 6(H 2 O) 0.89g is dissolved in deionized water and added to the above 0.7Mol / L Ba 2+ solution, after stirring to obtain a homogeneous solution concentration of 0.7Mol / L, measure urea (with a metal ion molar ratio of 18:1) and dissolve it in deionized water to make a 0.05Mol / L urea solution, add it to the above-mentioned homogeneous solution, and then Add 90% ammonium sulfate [(NH 4 ) 2 SO 4 ] (ratio to the amount of metal ion substance is 1:10) is used as a dispersant, and the above mixed solution is fully stirred to obtain a homogeneous solution. The homogeneous solution was heated in a water bath set at 99° C. and stirred continuously with a magnetic stirrer. After 3 hours, a white colloid was obtained. The above-mentioned colloid is subjected to suction filtrati...

Embodiment 3

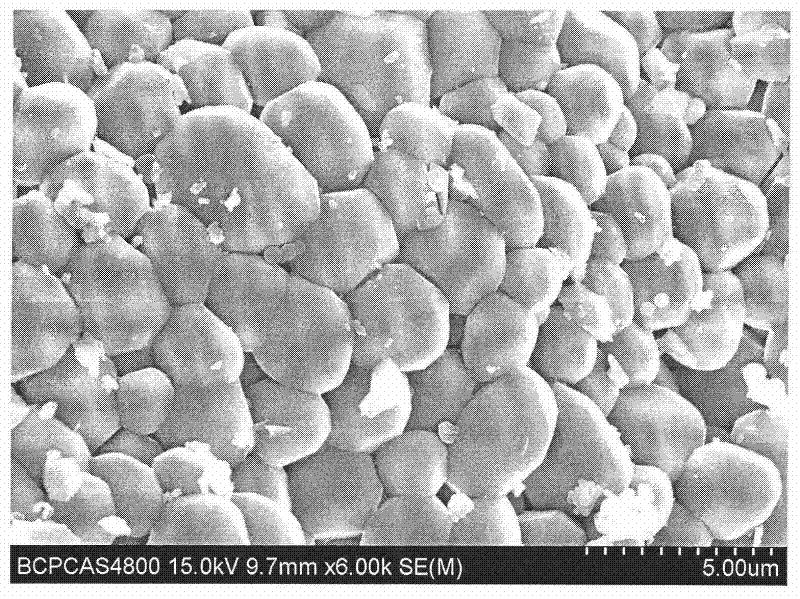

[0038] According to Ba 0.5 MgAl 11 o 17 : 0.4Eu weighed and weighed Ba(NO 3 ) 2 1.31g, Mg(NO 3 ) 2 ·6H 2 O2.56g, Al(NO 3 ) 3 9H 2 O 41.27g and Eu(NO 3 ) 3 6(H 2 O) 1.78g was dissolved in deionized water and stirred to obtain a 1Mol / L homogeneous solution. Measure urea (15:1 with the molar ratio of metal ions) and dissolve it in deionized water to make a 5Mol / L urea solution and add it to the above homogeneous solution In, add 90% ammonium sulfate [(NH 4 ) 2 SO 4 ] (ratio to the amount of metal ion substance is 1:10) is used as a dispersant, and the above mixed solution is fully stirred to obtain a homogeneous solution. The homogeneous solution was heated in a water bath set at 86° C. and stirred continuously with a magnetic stirrer. After 4 hours, a white colloid was obtained. Above-mentioned colloid is carried out suction filtration, the suction filtration product is washed with deionized water (with the volume ratio of the product obtained by suction filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com