A reinforced waterproof floating cable

A floating cable, waterproof technology, used in floating cables, insulated cables, cables, etc., can solve the problems of long-term normal use of cables, shortened cable service life, discounted cable waterproof performance, etc., to extend service life and improve resistance. Tensile performance, the effect of enhancing the waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

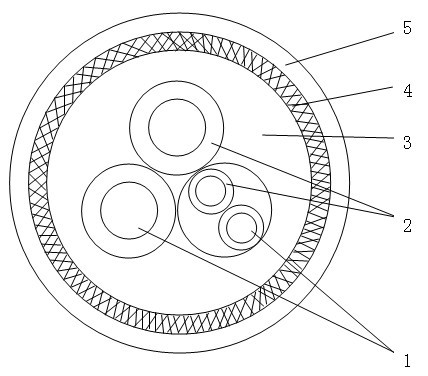

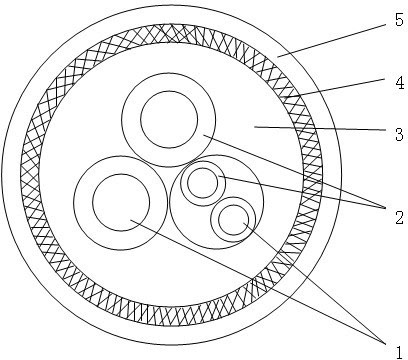

[0009] Such as figure 1 As shown, the floating cable of the present invention includes a cable core located at the center of the cable, and the cable core is composed of a conductor core 1 and an insulating layer 2 covering the conductor core 1 . A foamed inner liner 3 is filled outside the cable core, and a braided reinforcement layer 4 and a waterproof outer sheath 5 are sequentially arranged outside the foamed inner liner 3 .

[0010] Wherein, the filling of the foamed inner liner 3 is used to increase the outer diameter of the reinforced waterproof floating swimming pool cleaning cable, so that the volume of the cable is increased, thereby generating sufficient buoyancy, and the foamed inner liner 3 is due to the use of The foam structure makes it very light in weight, so that the cable can float on the water surface without sinking.

[0011] The insulating layer 2 covering the conductor core 1 is made of cross-linked polyethylene XLPE material, which has the advantages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com