Multi-energy comprehensive utilization and water temperature control method in industrialized aquaculture

A technology for aquaculture water and aquaculture, applied in application, fish farming, energy-saving heating/cooling, etc., can solve problems such as ground surface sinking, waste of groundwater resources, air pollution, etc., and achieve high energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

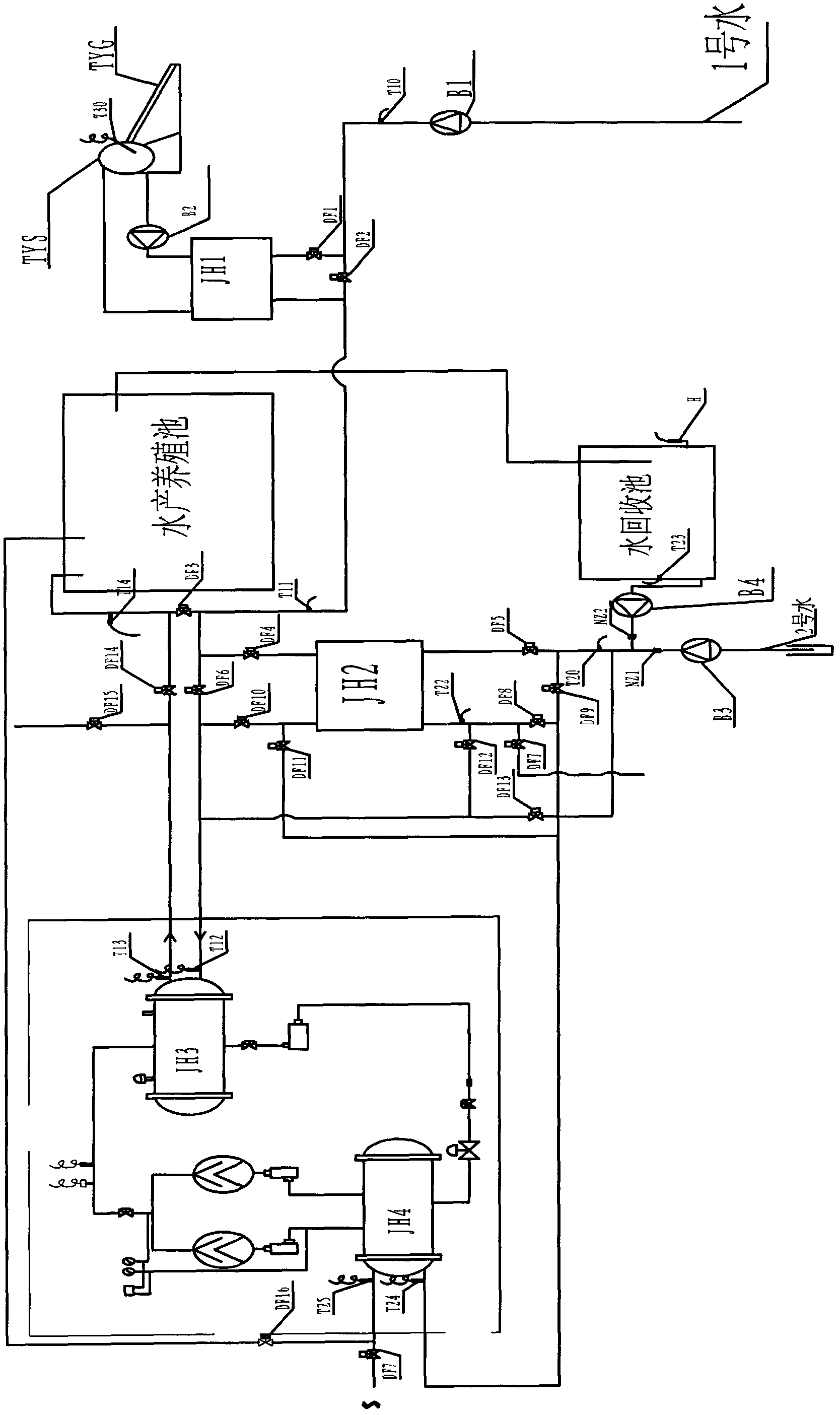

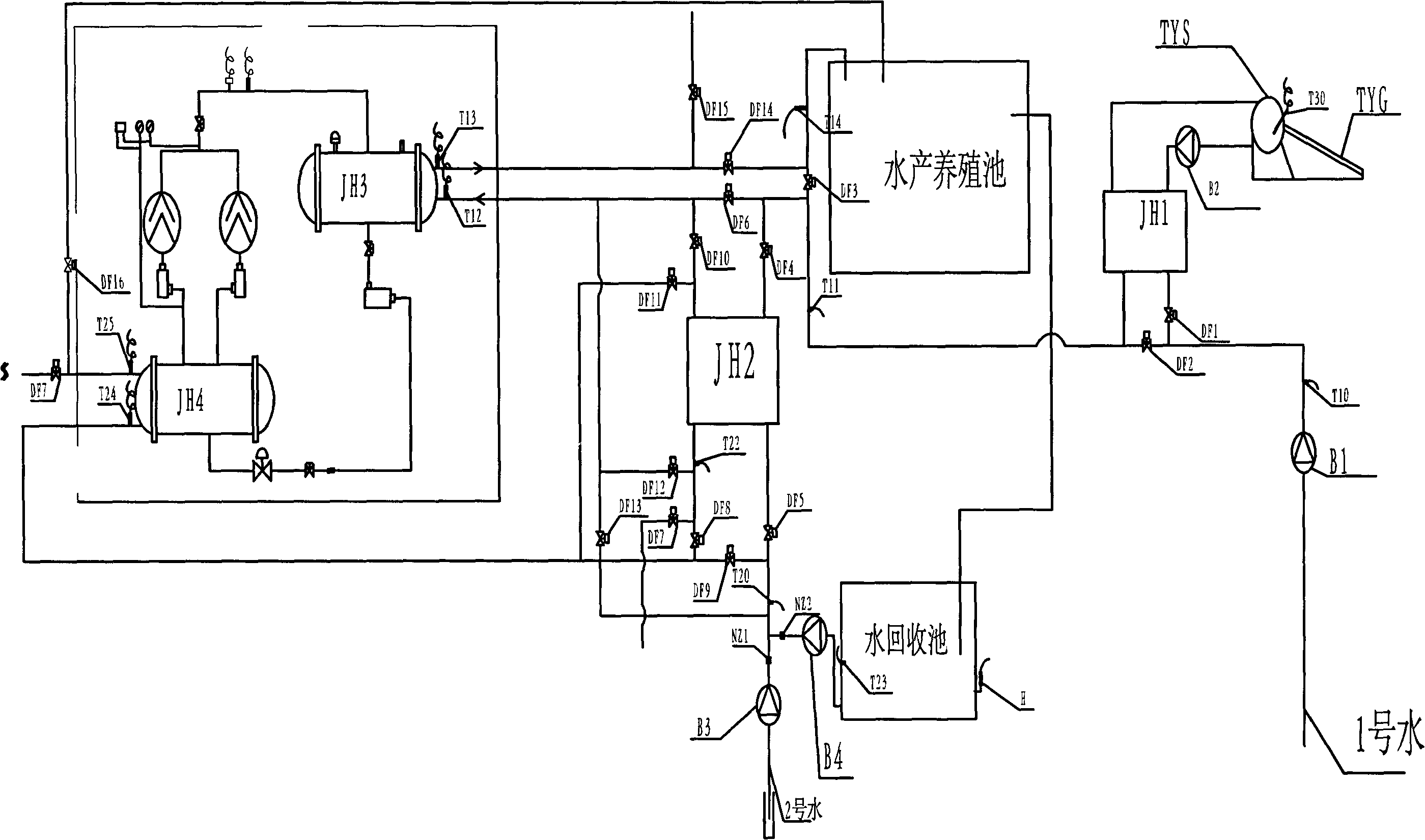

[0031] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0032] see figure 1 , the steps of multi-energy comprehensive utilization and heating of the present invention are as follows:

[0033] Step (1): Detect the temperature T10 of No. 1 water (aquaculture water, the same below) and compare it with the water temperature T30 in the solar water tank. If the value of ΔT1=T30-T10 reaches the set value (such as ΔT1≥5°C), The solenoid valve DF1 is opened, and the water pump B1 and the water pump B2 are started at the same time. The normal temperature water of No. 2 water (deep well water, the same below) passes through the solar heat exchanger (JH1) for heat exchange and extracts the heat energy of the solar energy; after detecting the solar heat exchanger (JH1) The water temperature T11 of the No. 1 water at the end, compare T11 with the upper limit T1 and lower limit T2 of the water temperature setting required by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com