Catalytic reactor comprising catalytic structure providing improved gas flow distribution

A catalytic reactor and reactor technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical/physical chemical processes, etc., can solve the problems of lack of conductive heat transfer, minimize pressure drop, The effect of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

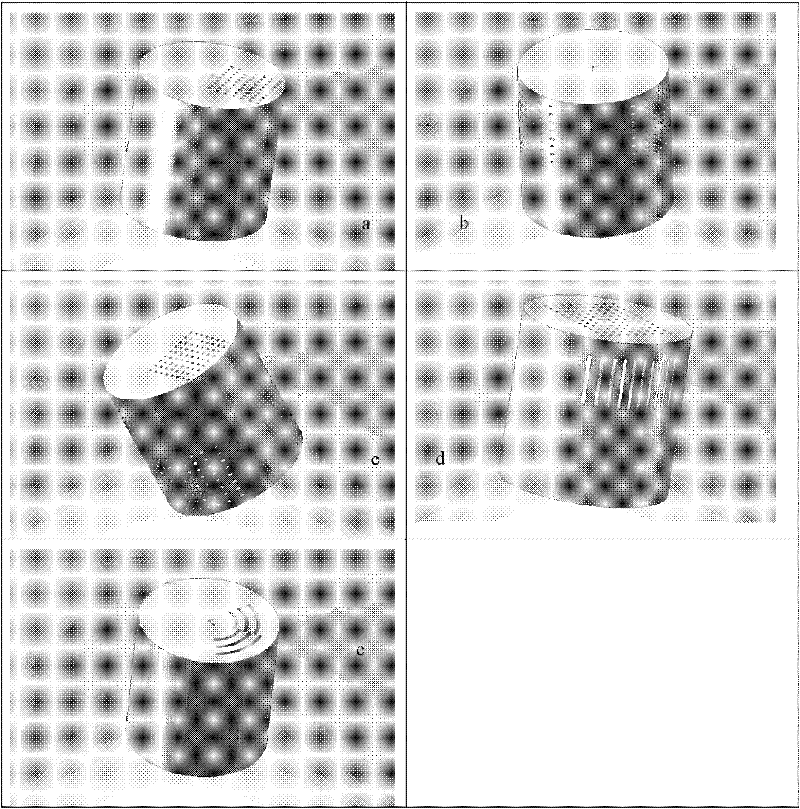

[0051] figure 2 4 modules with multiple channels are shown. Assuming a coaxial arrangement between the module and the reactor:

[0052] - in module "a", the channels of circular section are oriented in the axial direction of the reactor;

[0053] - in module "b", the channels of circular section are oriented radially of the reactor;

[0054] - in module "c", a first part of the channels of circular cross-section is oriented in the axial direction of the reactor, and a second part of the channels of circular cross-section is oriented radially of the reactor;

[0055] - in the module "d", the channels of circular section are oriented in the axial direction of the reactor, and the channel-shaped channels are oriented in the radial direction of the reactor;

[0056] - In module "e", the channels in the shape of curved grooves are oriented in the axial direction of the reactor.

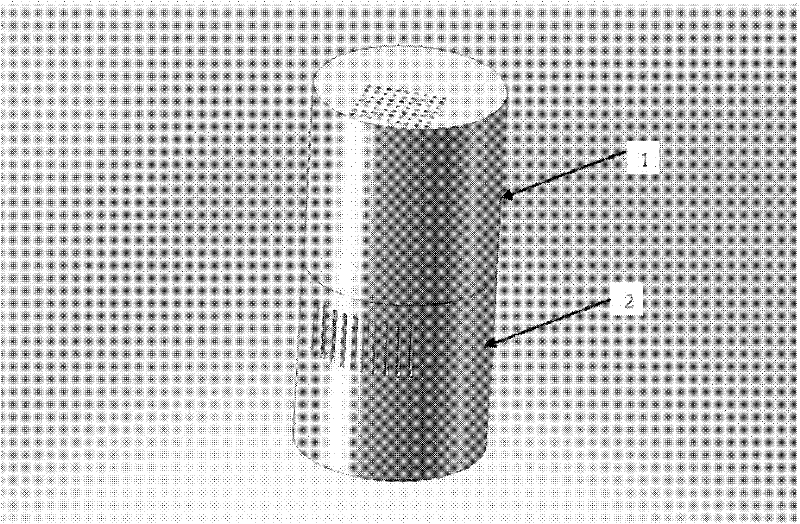

[0057] image 3 2 juxtaposed modules are shown, the first module (1) comprising channels of circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com