A Variable Displacement Intelligently Controlled Engine

An intelligent control and engine technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as large engine heat load, accelerated wear of parts, and difficulty in dissipating heat, to improve horsepower and efficiency, simple manufacturing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

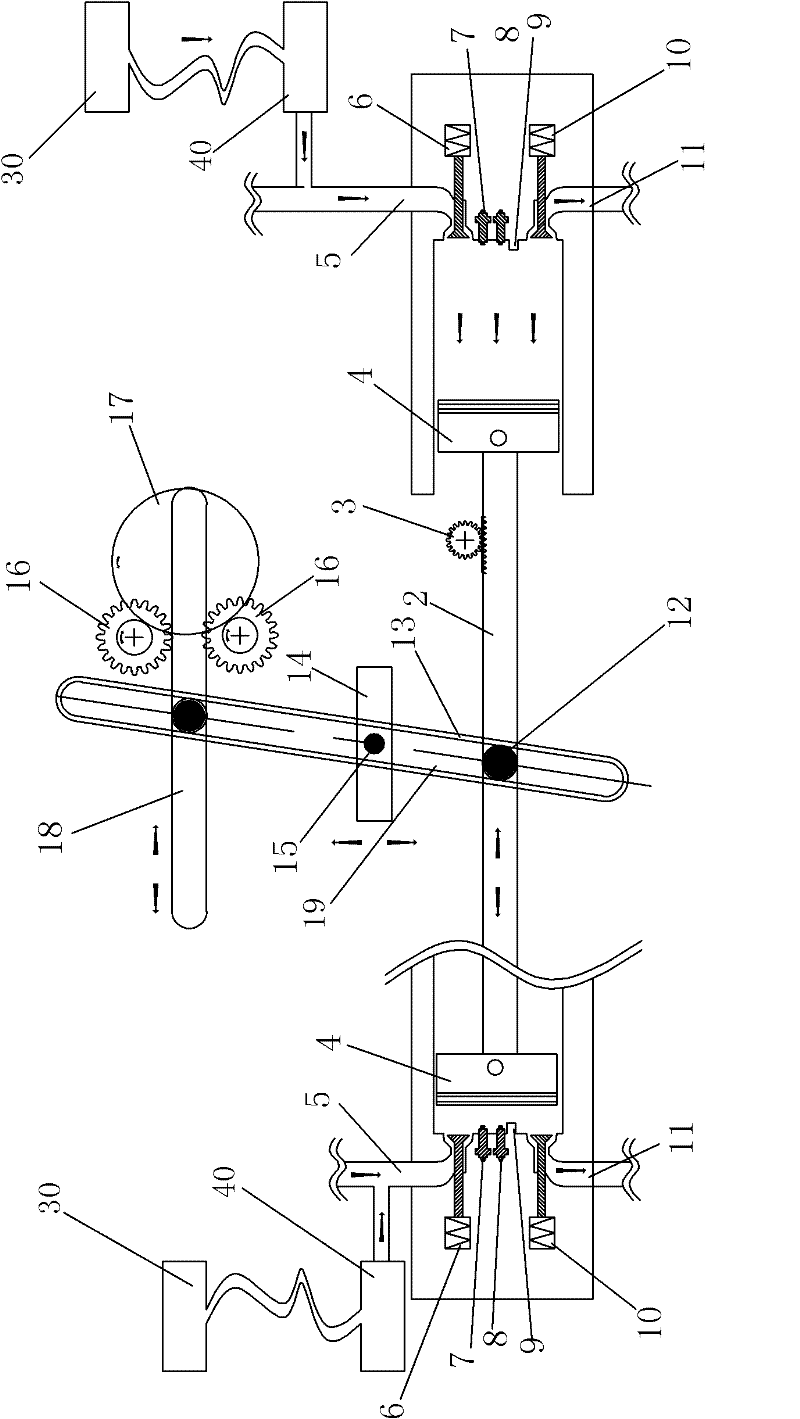

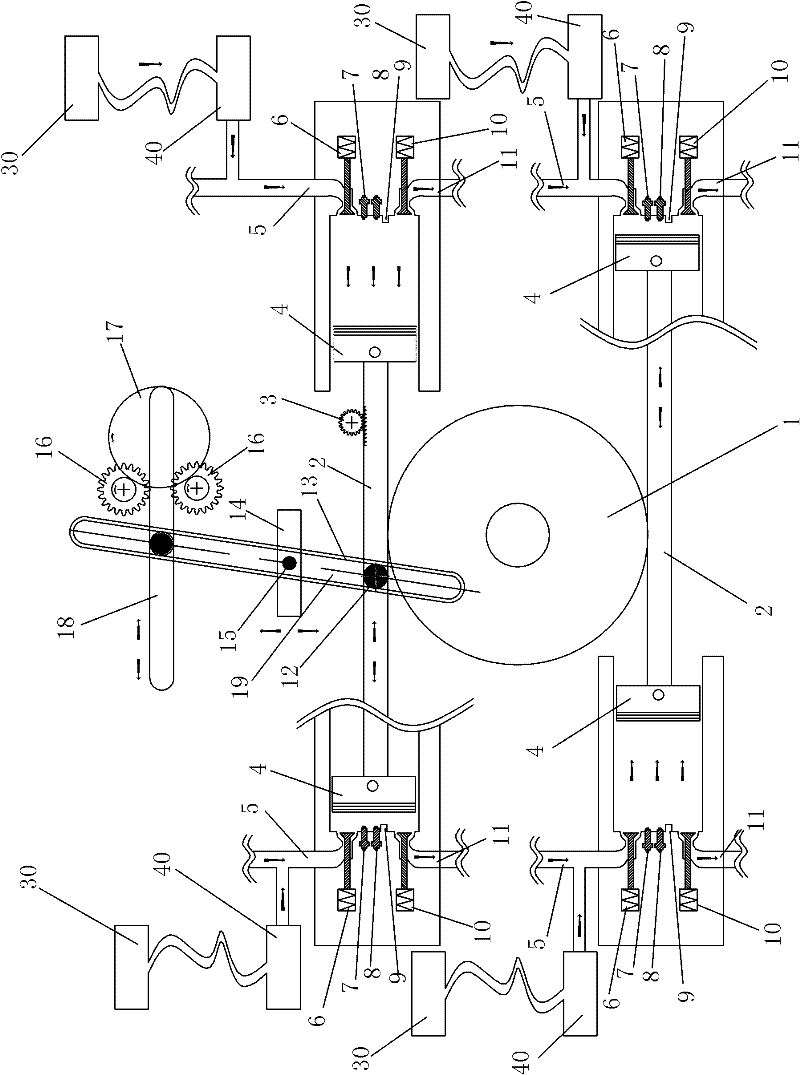

[0041] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and drawings:

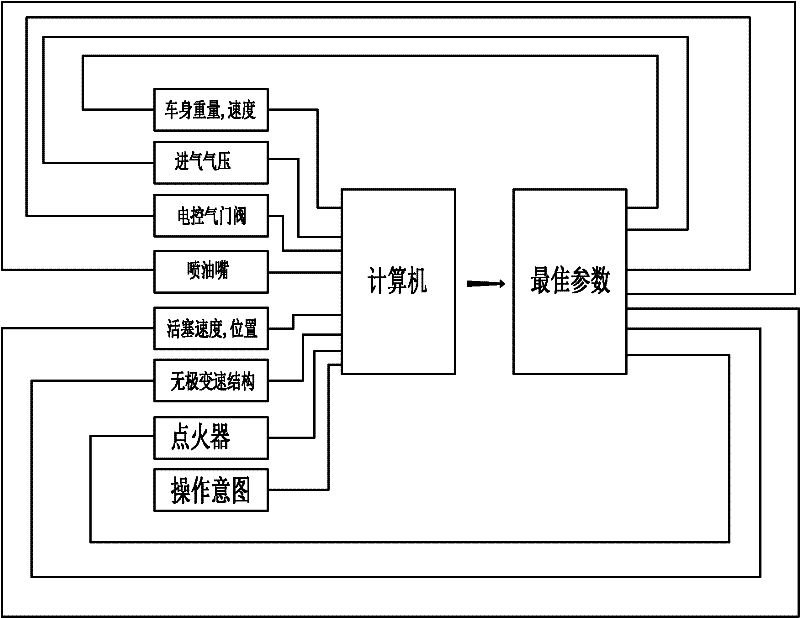

[0042] Such as figure 1 As shown, a variable displacement intelligently controlled engine includes a piston cylinder 20, a piston 4, an intake port 5, a first electronically controlled valve valve 6, a fuel injector 7, an igniter 8, a piston cylinder 20 located in an engine casing, The separation wall 9, the second electronically controlled valve valve 10, the exhaust port 11, the piston 4, the first electronically controlled valve valve 6, the fuel injector 7, the igniter 8, and the second electronically controlled valve valve 10 are respectively controlled by the vehicle Controlled by the computer system, two piston cylinders 20 and two pistons 4 are arranged in the engine shell. The two piston cylinders 20 and the piston 4 are arranged oppositely, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com