Two-channel ultrasonic flowmeter time difference detection device

An ultrasonic flowmeter, ultrasonic flow technology, applied in measurement devices, test/calibration devices, liquid/fluid solids measurement, etc., can solve the problems of reduced signal strength, limited versatility, redesign, etc. The effect of great versatility and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and in combination with practical embodiments.

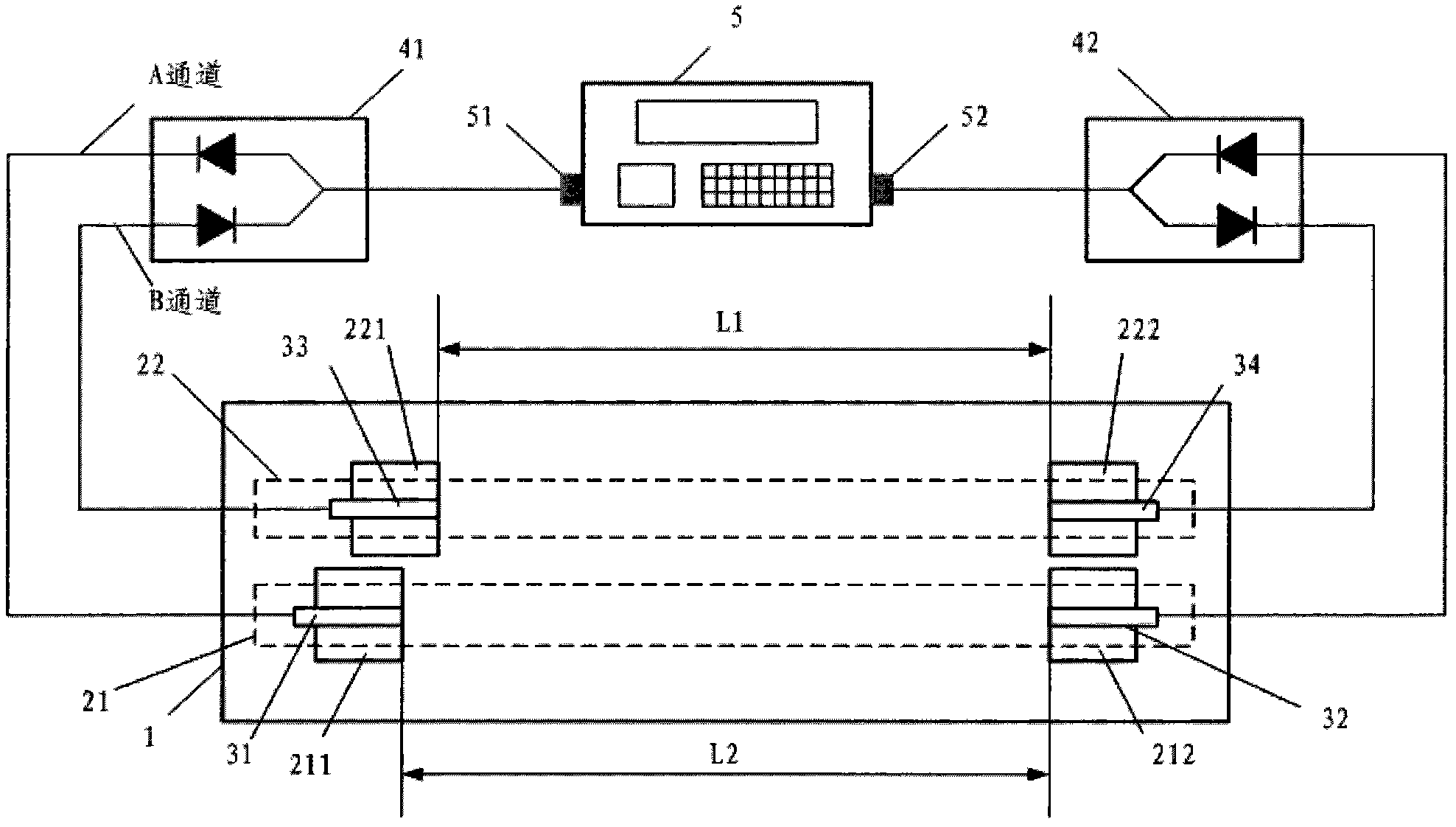

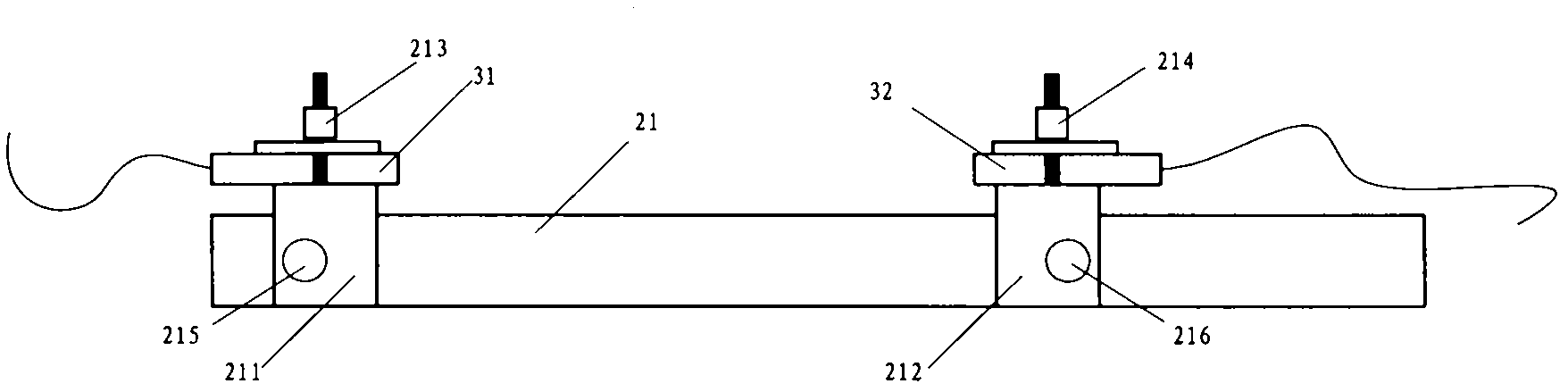

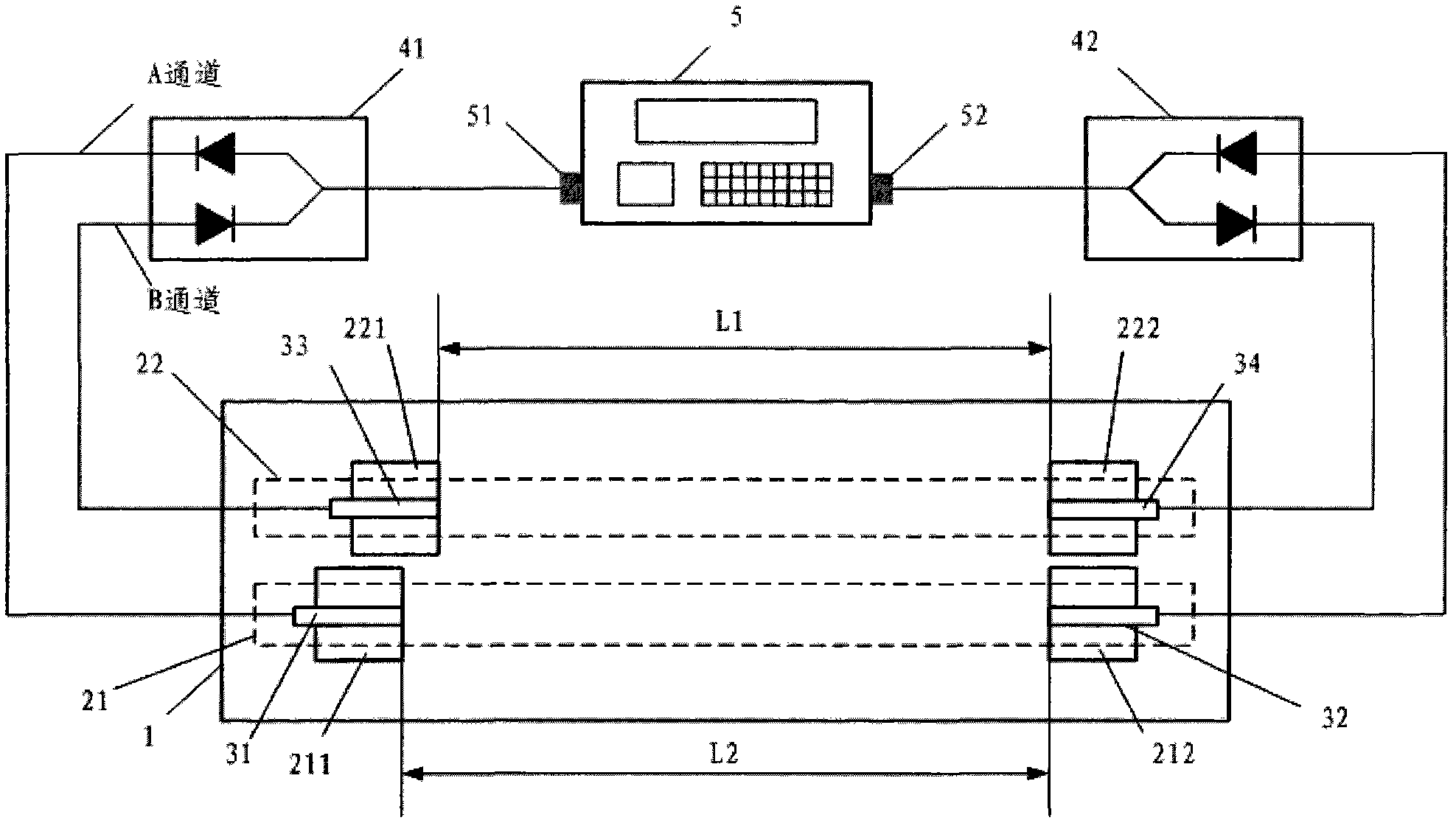

[0022] Such as figure 1 Shown is a schematic diagram of the structure of a two-channel time-of-flight ultrasonic flowmeter. The ultrasonic flowmeter forms two channels, A and B, and the flow velocity is obtained through the time difference between the two channels. Specifically, a liquid container is set in the measuring device, preferably the liquid container can be a liquid tank 1, in which there is a flowing liquid medium that can transmit ultrasonic signals, generally the same as the ultrasonic flowmeter measurement medium, the liquid medium There is a standard flow rate in the liquid tank, and its flow direction is relative to figure 1 It can be left or right, as long as the flow rate is stable and the flow direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com