Automatic Calibration Device and Calibration Method for Digital Vibration Meter

An automatic calibration and vibrometer technology, applied in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of high labor intensity, long calibration time, and low degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

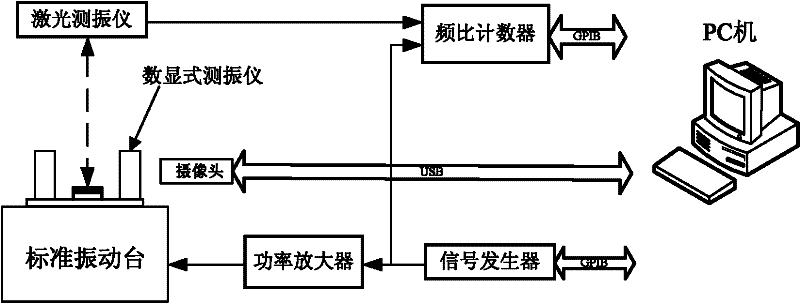

[0062] refer to figure 1 , 3 -7;

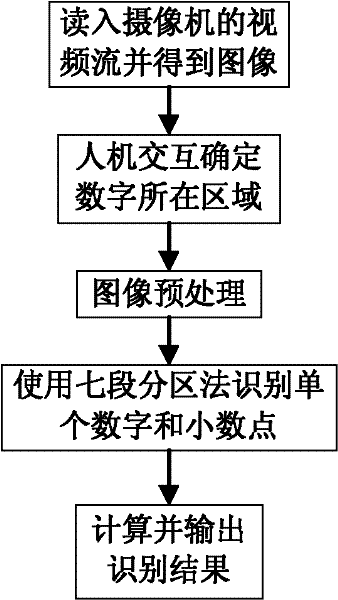

[0063] The automatic calibration device of the digital display vibrometer includes a signal generator whose amplitude and frequency of the output sinusoidal signal can be independently and continuously adjusted, a power amplifier connected to the signal generator, and a power amplifier connected to the power amplifier A connected standard vibrating table, a camera for recording the displayed value of the digital display vibrometer, a laser vibrometer for measuring the actual vibration level of the standard vibrating table, and a laser vibrometer for measuring the output signal of the laser vibrometer and the occurrence of the signal A frequency ratio counter that outputs the frequency ratio of the sinusoidal signal, and a processor; the calibrated digital vibrometer is installed on the standard vibration table.

[0064] Described processor is respectively connected with described signal generator, described video camera and described freque...

Embodiment 2

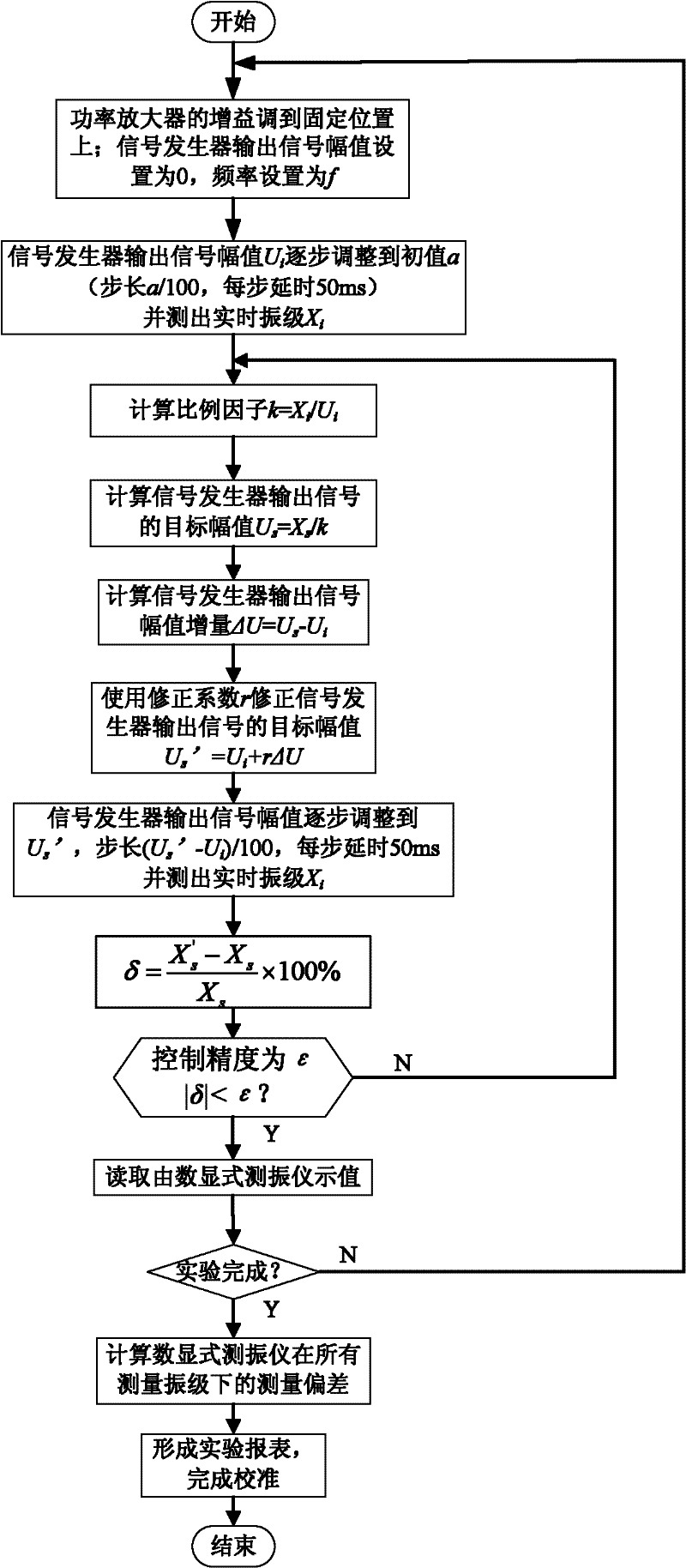

[0105] refer to figure 2

[0106] The method for calibrating the digital display vibrometer using the automatic calibration device of the digital display vibrometer includes the following steps:

[0107] 1), the gain of the power amplifier is adjusted to a predetermined position; the processor sets the amplitude of the output signal of the signal generator to 0, and the frequency is set to the specified value f in the test task list (thereafter remains unchanged);

[0108] 2), the signal generator output signal amplitude U i Increase to the initial value a, in order to prevent the increase of the output signal amplitude of the signal generator from impacting the standard vibration table, gradually increase the output amplitude of the signal generator with a / 100 as the step size, and delay 50ms per step , and then measure the real-time vibration level X of the standard shaking table i ;

[0109] 3), the real-time vibration level of the standard shaking table X i The measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com