Photoelectric response characteristic calibration method for two-dimensional imaging device

A technology of two-dimensional imaging and calibration method, which is used in the testing of machine/structural components, instruments, optical instruments, etc., and can solve the problems of low utilization rate of light energy, inability to achieve large-scale calibration, and unusable calibration light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

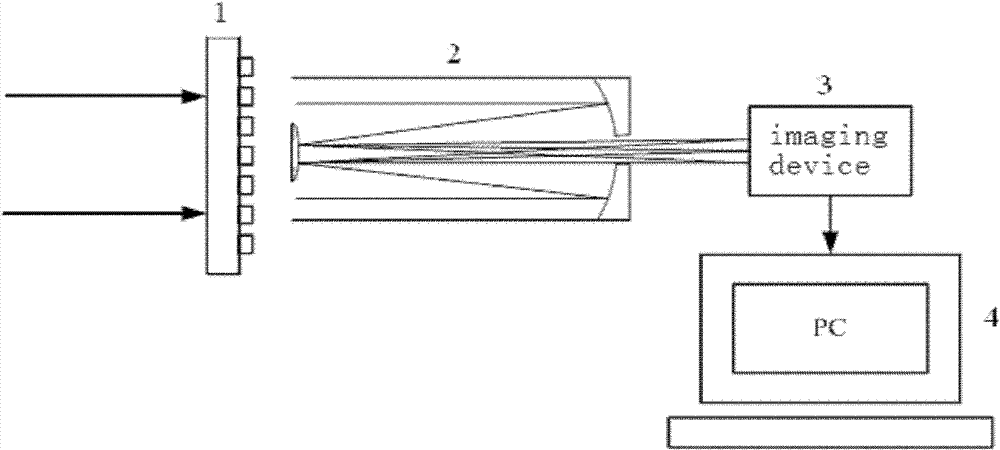

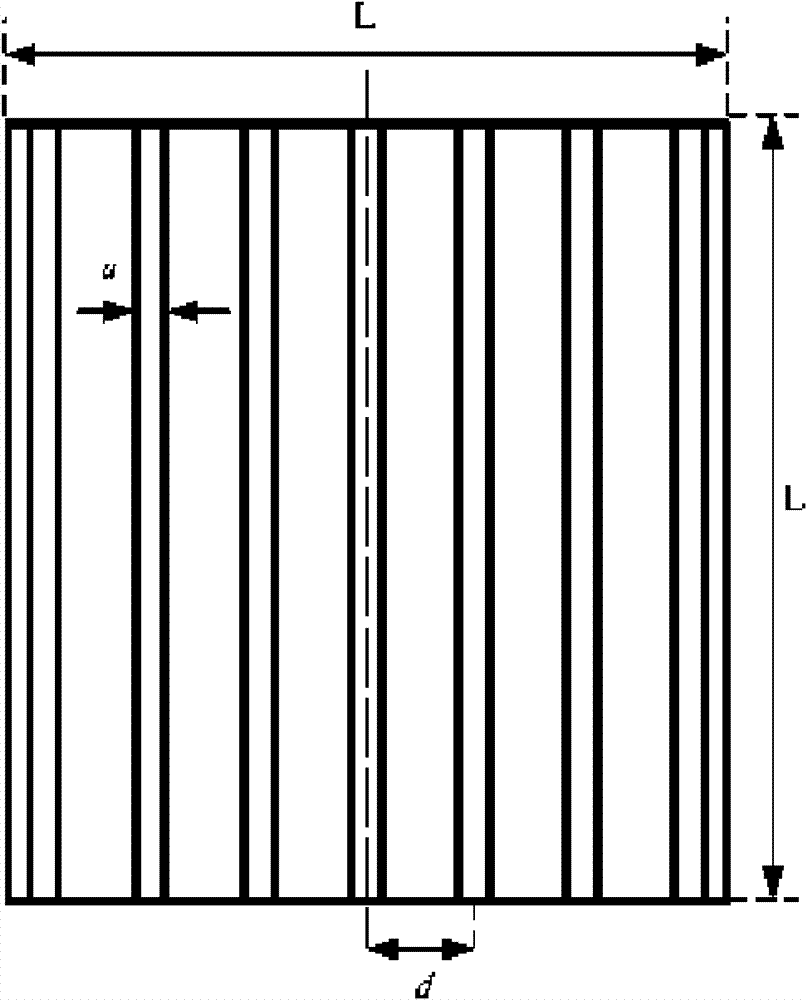

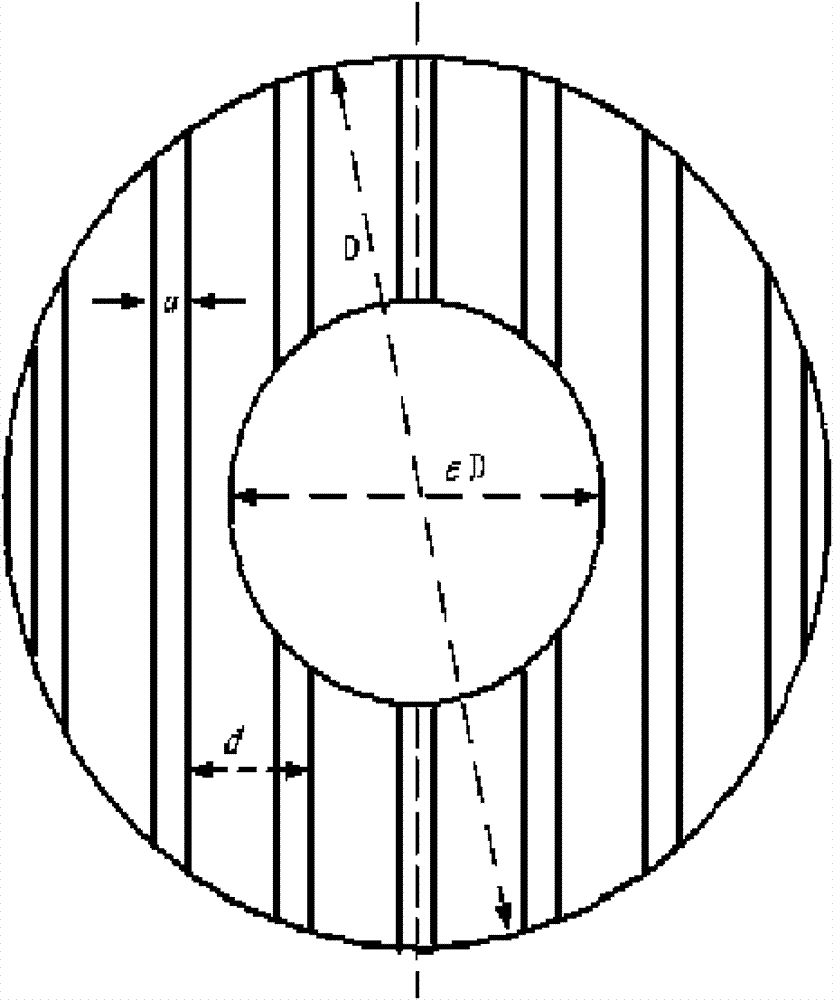

[0044] Specific embodiment: To calibrate the photoelectric response characteristics of an infrared CCD camera with unknown characteristics to a certain infrared laser. The incident beam is a parallel plane beam with a diameter of φ=120mm. The focusing optical system 2 adopts a reflective Cassegrain system. The outer diameter of the incident end is D=120mm, the central blocking ratio is ε=0.42, the effective focal length is f=2.47m, and the CCD photosensitive surface The number of pixels is 128×128, the size of a single pixel is 30μm×30μm, and the digital signal output is 14bit. According to the basic situation and experience of the infrared CCD camera, the linear response area of the CCD to be measured wavelength light contains at least the gray value The range is 1000-4000 ADU, and the scribed direction of the line diffraction grating is placed in front of the vertical direction in close contact with the focusing optical system. From the above parameters, it is required tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com