Water-reducing and early-strength antifreeze

A technology of antifreeze and early strength agent, applied in the field of water-reducing early strength antifreeze agent, can solve problems such as inability to effectively ensure construction quality and lack, and achieve excellent antifreeze and early strength performance, accelerated construction, and good workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

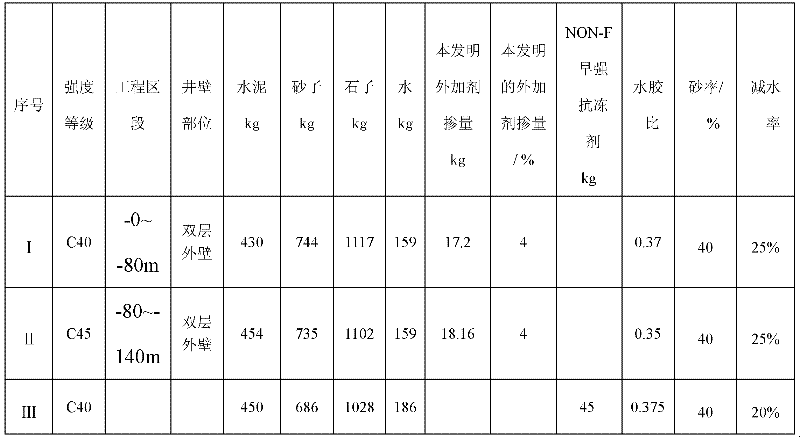

Examples

Embodiment 1

[0022] The naphthalene-based high-efficiency water-reducer is SSF-1000 naphthalene-based water-reducer.

[0023] The early strength agent is sodium sulfate.

[0024] Mineral admixture fly ash: GB / T 18376-2002 Class II.

[0025] Weigh according to the following proportions: 20kg of water reducing agent, 16kg of early strength agent, 8kg of antifreeze calcium nitrite, and 56kg of fly ash as mineral admixture.

[0026] Prepare as follows:

[0027] Stir the naphthalene-based high-efficiency water reducer and the mineral admixture fly ash for 3 minutes, then add the early strength agent and antifreeze in turn and stir for 7 minutes.

[0028] The application of the water-reducing and early-strength antifreeze agent prepared in this example in the construction of the cucurbitacin coal mine shaft freezing method (the temperature is -10~-15°C):

[0029] The sand is made of coarse sand produced in Hangjin Banner, with a fineness modulus of 3.2;

[0030] The stone is made of Wuhai cr...

Embodiment 2

[0039] The naphthalene-based high-efficiency water-reducer is FDN naphthalene-based water-reducer.

[0040] Potassium sulfate is used as early strength agent.

[0041] Mineral admixture fly ash: GB / T 18376-2002 level II.

[0042] Weigh according to the following proportions: 18kg of water reducing agent, 20kg of early strength agent, 9kg of antifreeze calcium nitrite, and 53kg of fly ash as mineral admixture.

[0043] Prepare as follows:

[0044] Stir the naphthalene-based high-efficiency water reducer and the mineral admixture fly ash for 3 minutes, then add the early strength agent and antifreeze in turn and stir for 7 minutes.

Embodiment 3

[0046] The naphthalene-based high-efficiency water-reducer is SSF-1000 naphthalene-based water-reducer.

[0047] The early strength agent is sodium sulfate.

[0048] Mineral admixture fly ash: GB / T 18376-2002 level II.

[0049] Weigh according to the following proportions: 18kg of water reducing agent, 20kg of early strength agent, 9kg of antifreeze calcium nitrite, and 53kg of fly ash as mineral admixture.

[0050] Prepare as follows:

[0051] Stir the naphthalene-based high-efficiency water reducer and the mineral admixture fly ash for 3 minutes, then add the early strength agent and antifreeze in turn and stir for 7 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com