A cleaning agent for cleaning ion exchange resin engine oil pollution

A technology of ion exchange resin and cleaning agent, applied in detergent compositions, detergent compounding agents, non-ionic surface active compounds, etc., can solve the problem of cleaning oil stains, ionic surfactant pollution, and inability to regenerate ion exchange resins Ion exchange etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

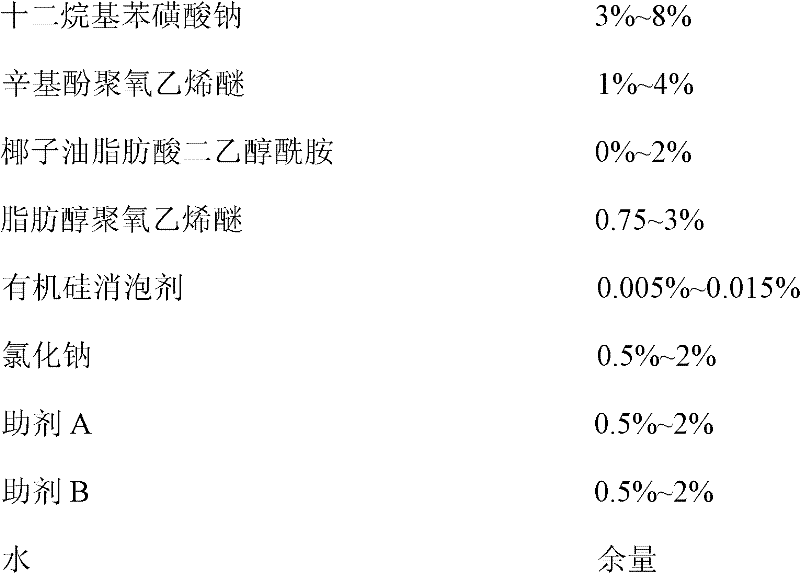

[0013] Embodiment one: a kind of cleaning agent that is used to clean ion-exchange resin motor oil pollution, concrete component and its weight ratio are as follows:

[0014]

[0015]

[0016] Its preparation method is as follows:

[0017] 1. Add water into the container according to the ratio, add sodium tripolyphosphate and sodium chloride at room temperature and stir to completely dissolve sodium tripolyphosphate and sodium chloride;

[0018] 2. Add the organosilicon defoamer JF-1148 produced by Tianjin Jinfeng Defoamer Co., Ltd., the surfactant sodium dodecylbenzenesulfonate, and the octylphenol OP-10 into the container in sequence Polyoxyethylene ether, fatty alcohol polyoxyethylene ether and isopropanol are stirred and fully dissolved to form a cleaning agent for ion exchange resin contaminated by oil.

Embodiment 2

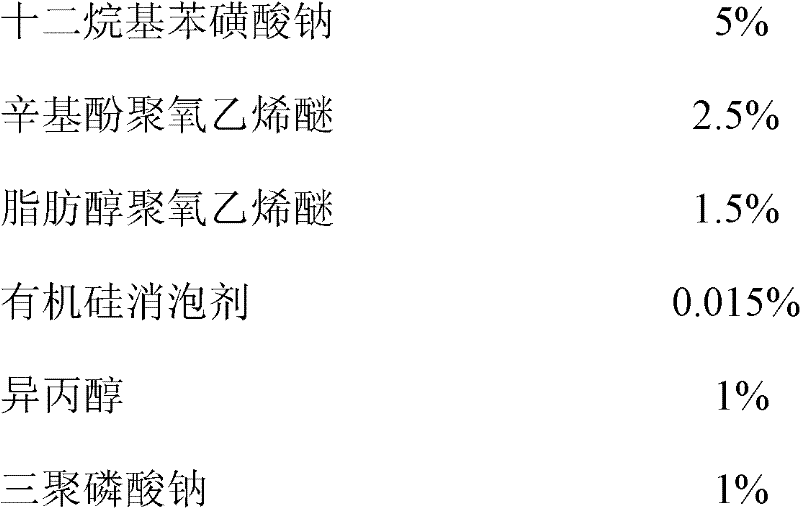

[0019] Embodiment two: a kind of cleaning agent that is used to clean ion-exchange resin machine oil pollution, concrete component and weight ratio thereof are as follows:

[0020]

[0021] Its preparation method is as follows:

[0022] 1. Add water into the container according to the ratio, add sodium tripolyphosphate and sodium chloride at room temperature and stir to completely dissolve sodium tripolyphosphate and sodium chloride;

[0023] 2. Add CF901 silicone defoamer, surfactant sodium dodecylbenzenesulfonate, and OP-10 octylphenol polycarbonate produced by Jiangsu Changfeng Organosilicon Defoamer Co., Ltd. Oxyethylene ether, 1:2 type 6501 coconut oil fatty acid diethanolamide, fatty alcohol polyoxyethylene ether and ethanol are stirred and fully dissolved to form a cleaning agent for ion exchange resin contaminated by oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com