A composite sound-absorbing structure

A technology of sound absorption and panel, applied in the direction of sound-generating equipment, instruments, etc., can solve the problems of poor sound absorption, poor sound absorption effect, low frequency sound absorption effect, etc., and achieve the effect of wide sound absorption frequency band and sound absorption performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

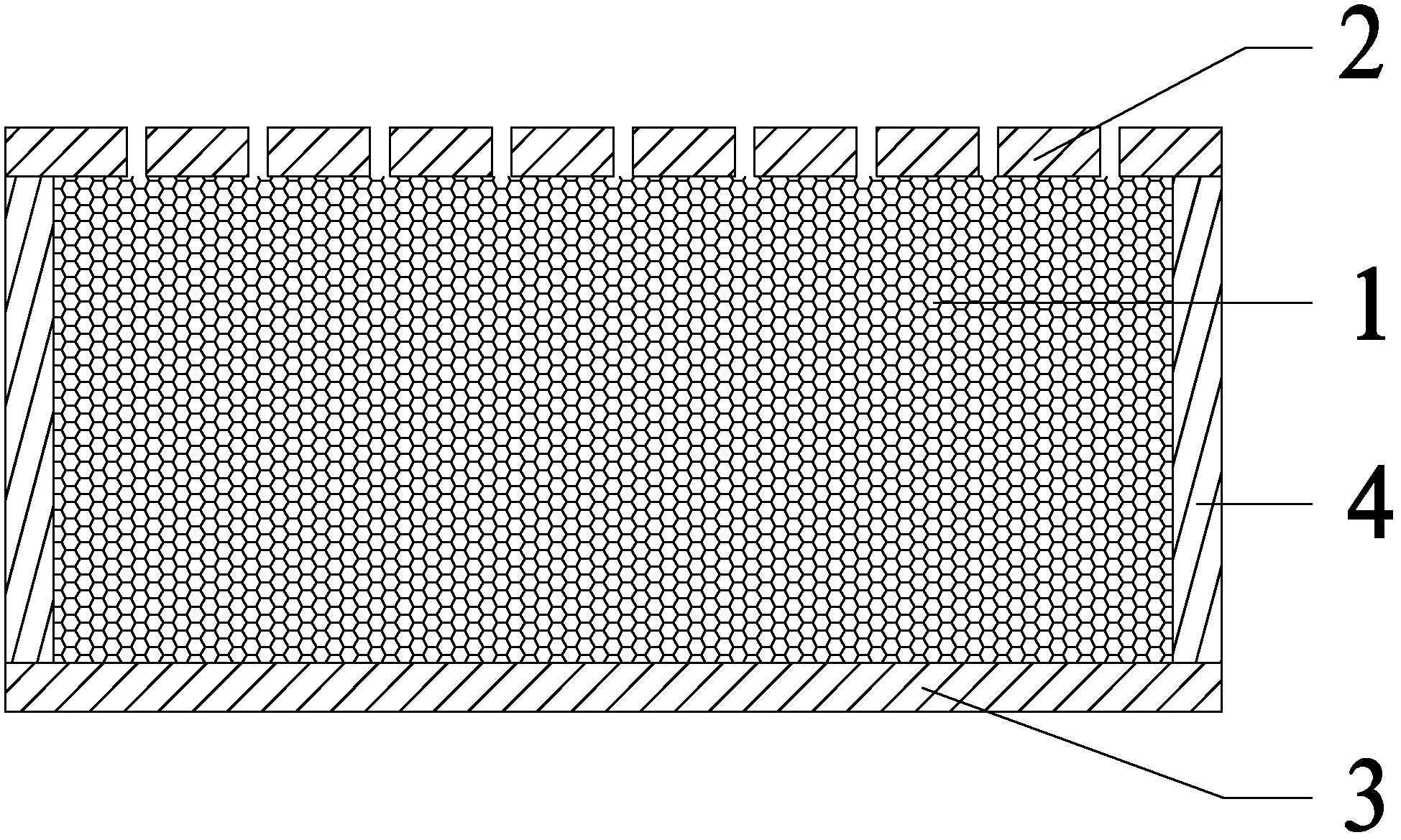

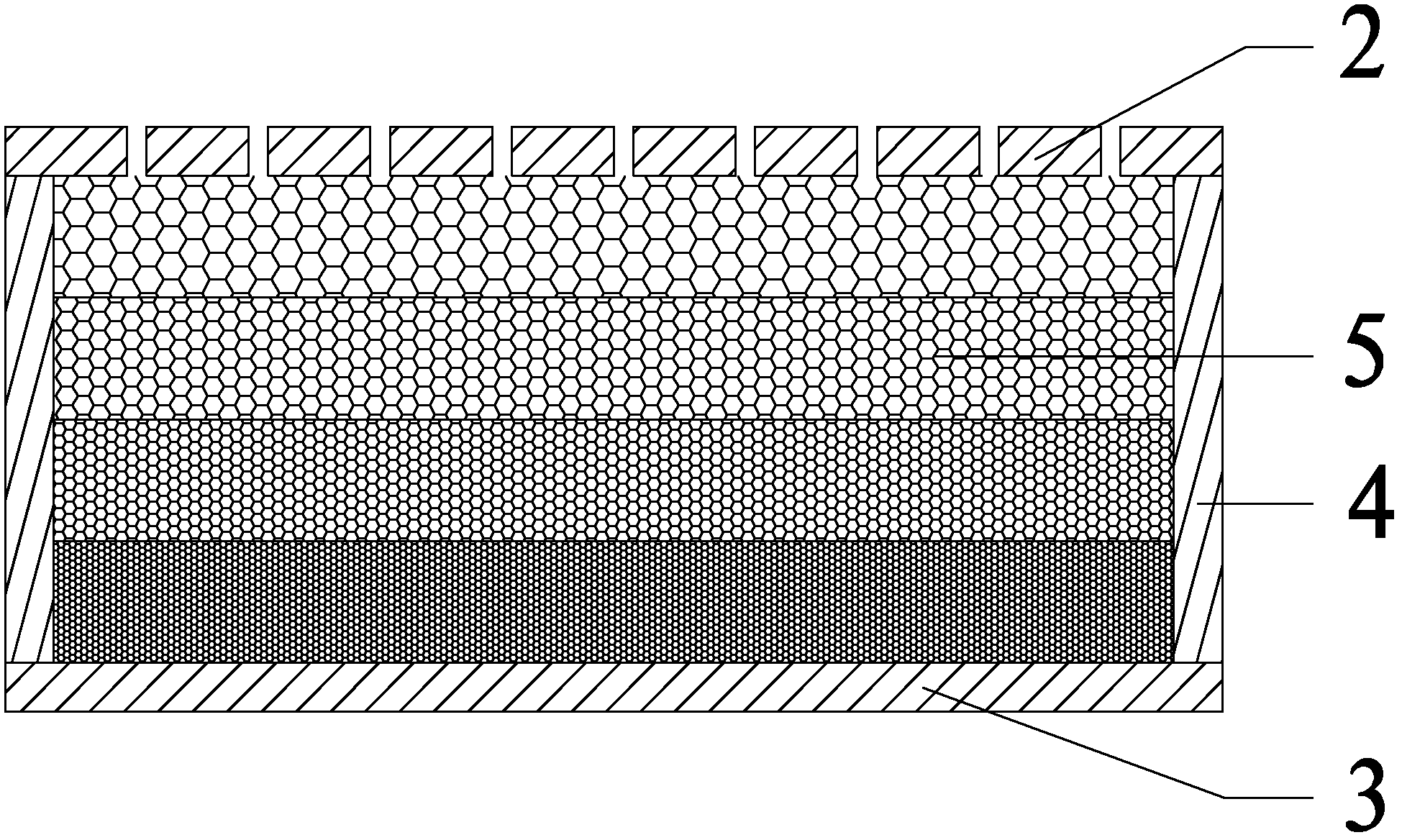

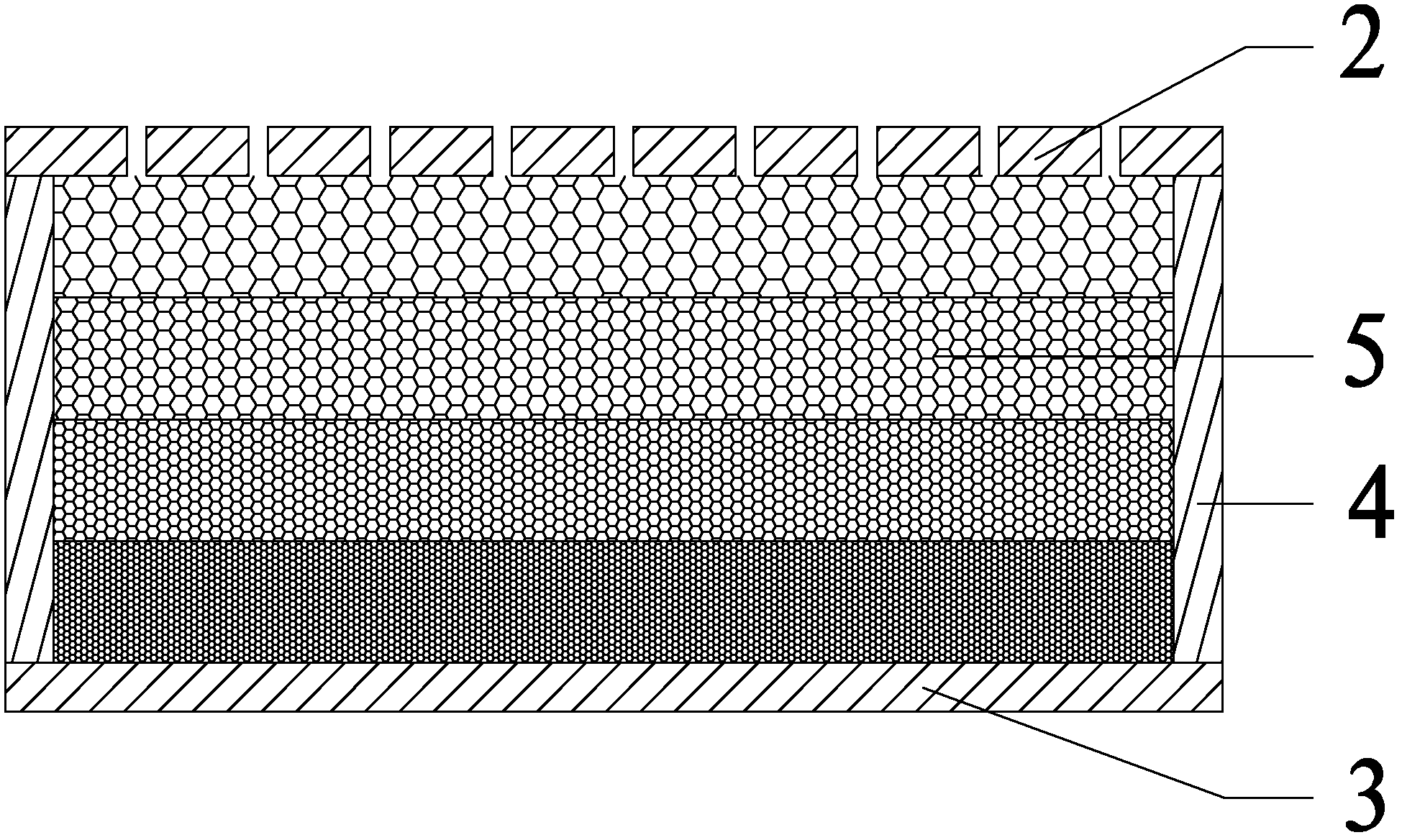

[0027] refer to figure 1 . The composite sound-absorbing structure is composed of glass wool encapsulated by an upper panel 2 , a lower panel 3 and a side panel 4 . The space enclosed by the upper panel 2, the lower panel 3 and the side panel 4 is filled with glass wool; from the upper panel 2 to the lower panel 3, the porosity of the filled glass wool gradually changes from small to large or from large to small . The upper panel 2 is made of an iron plate with a perforation rate of 10%, a thickness of 1.2 mm, and a perforation diameter of 1.2 mm; the lower panel 3 and the side panels 4 are all non-porous iron plates with a thickness of 1.2 mm. The shape of the composite sound-absorbing structure is a cuboid, and the distance from the upper panel 2 to the lower panel 3 is equal to 6 cm.

[0028] The composite sound-absorbing structure proposed in this example can be installed on the surface of the wall to reduce the sound level in the room; it can also be used as the side w...

Embodiment 2

[0030] refer to figure 1 . The composite sound-absorbing structure is composed of a porous material 1 encapsulated by an upper panel 2 , a lower panel 3 and a side panel 4 . The space enclosed by the upper panel 2 , the lower panel 3 and the side panel 4 is filled with the porous material 1 ; the porosity of the porous material 1 decreases uniformly from 99% to 90% from the upper panel 2 to the lower panel 3 . The porous material 1 is made of one of polyurethane foam or urea foam. The upper panel 2 is made of an iron plate with a perforation rate of 5%, a thickness of 1.2 mm, and a perforation diameter of 1.5 mm; the lower panel 3 and the side panels 4 are all non-porous iron plates with a thickness of 1.2 mm. The shape of the composite sound-absorbing structure is a cuboid, and the distance from the upper panel 2 to the lower panel 3 is equal to 6 cm.

[0031] The composite sound-absorbing structure proposed in this example can be installed on the surface of the wall to re...

Embodiment 3

[0033] refer to figure 1 . The composite sound-absorbing structure is composed of glass wool encapsulated by an upper panel 2 , a lower panel 3 and a side panel 4 . The space enclosed by the upper panel 2, the lower panel 3 and the side panel 4 is filled with glass wool; the bulk density of the filled glass wool is from 48Kg / m in the direction from the upper panel 2 to the middle position of the upper and lower panels 3 Gradually increase to 128Kg / m 3 ; Between the lower panel 3 and the middle position of the upper and lower panels, the bulk density of the filled glass wool is from 48Kg / m in the direction from the lower panel 3 to the middle position of the upper and lower panels 3 Gradually increase to 128Kg / m 3. Both the upper panel 2 and the lower panel 3 are made of an iron plate with a perforation rate of 6.5%, a thickness of 1 mm, and a perforation diameter of 1.2 mm; the side panel 4 is made of a non-porous iron plate with a thickness of 1.2 mm. The shape of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com