Fabrication method of trench type super junction device and obtained device

一种制作方法、超级结的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决难度大、成本增加等问题,达到增加击穿电压、减低成本、工艺难度减低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The first embodiment of the method of the present invention comprises the following steps:

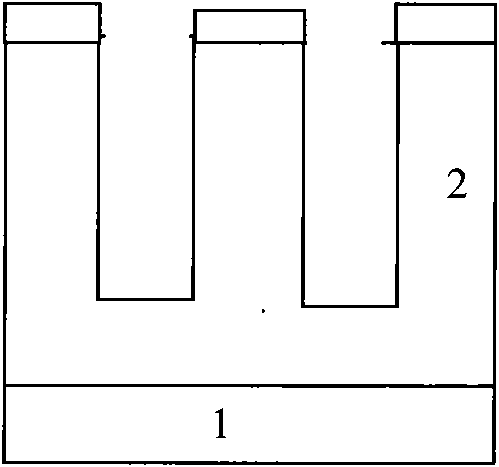

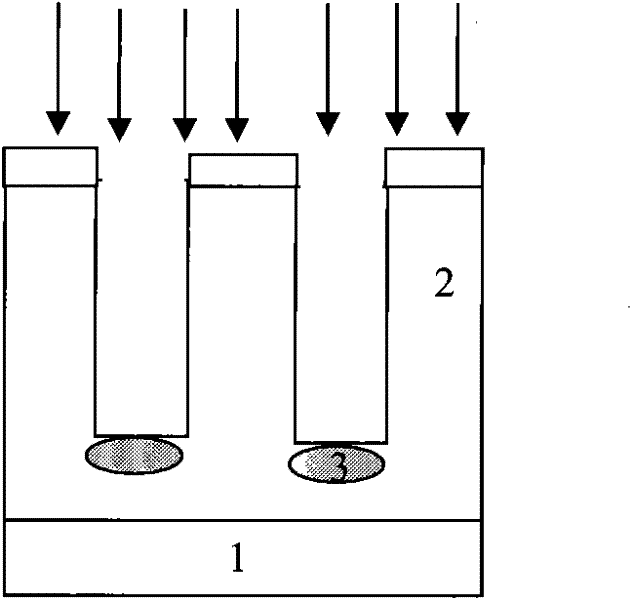

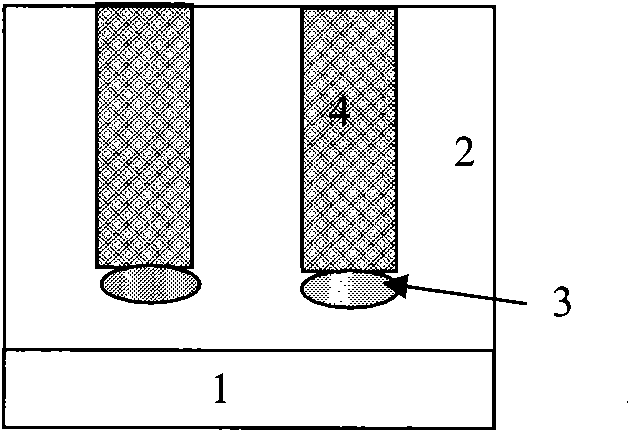

[0018] Step 1, see Figure 1A As shown, the N- epitaxial layer 2 is formed on the N+ silicon substrate 1, and the resistivity of N+ is generally 0.001-0.003 ohm.cm; the thickness and resistivity of the epitaxial layer are determined according to the requirements of device design, such as for BVDS600V device, its resistivity is generally selected at 2-10 ohm / cm, and its thickness is selected at 40-55 microns; a layer of silicon oxide film 31 is grown on the N-epitaxial layer 2 (this silicon oxide film can be used as a groove engraved etch mask, which can be used as a barrier layer during chemical mechanical polishing), and the groove pattern is obtained by groove photolithography (here, the groove can pass through the N epitaxy to the N+ substrate, or it can stay in the N epitaxy, .Depending on the requirements of the device design);

[0019] The silicon oxide film 31 can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com