Current collector plate of flow battery and flow battery

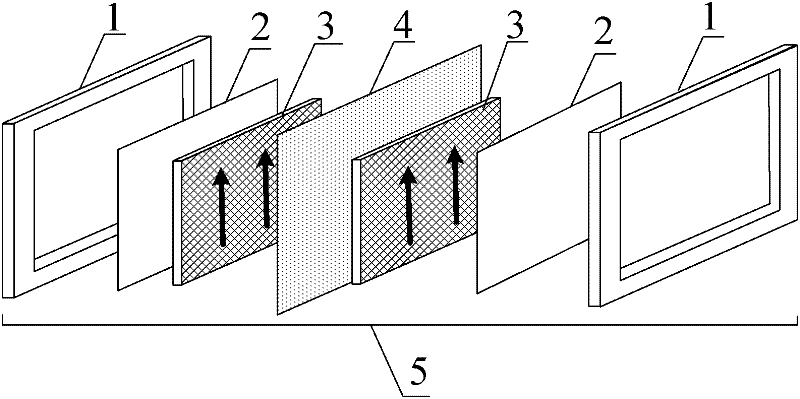

A liquid flow battery and collector plate technology, which is applied to fuel cell components, regenerative fuel cells, collectors/separators, etc., can solve the problem of uneven electrode reaction rate and reaction heat generation, lower battery charge and discharge performance and Problems such as service life and uneven electrolyte flow, to achieve the effect of reducing polarization, improving service life and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

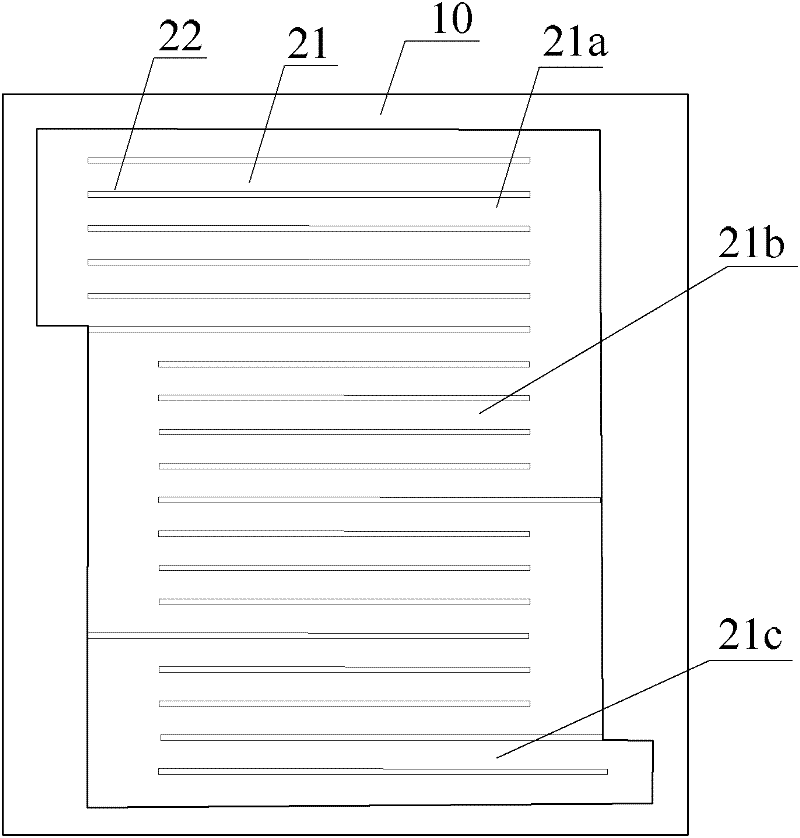

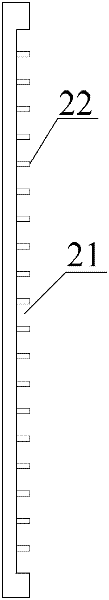

example 1

[0050] High-purity machinable graphite pole plate is used as the current collector plate material, and the flow field is engraved on it. The entire collector plate is rectangular 200mm×240mm, the thickness of the collector plate is 4mm, the depth of the runner groove is 1mm, the width of the runner groove is five times the width of the runner ridge, and the number of runners from the inlet to the outlet is six, respectively. Five, four, three and two. The charge-discharge coulombic efficiency of a single cell composed of the collector plate, the ion-exchange membrane and the graphite felt electrode is 92.5%, the voltage efficiency is 89%, and the energy efficiency is 82.3%.

example 2

[0052] High-purity machinable graphite pole plate is used as the current collector plate material, and the flow field is engraved on it. The entire collector plate is rectangular 200mm×240mm, the thickness of the collector plate is 4mm, and the channel width is five times that of the channel ridge width. Detour four times. The number of runners from the inlet to the outlet is divided into five groups, and the depths of the five groups of runners gradually decrease, which are 1.5mm, 1.3mm, 1.1mm, 0.9mm, and 0.7mm. The charge-discharge coulombic efficiency of a single cell composed of the collector plate, the ion-exchange membrane and the graphite felt electrode is 91.5%, the voltage efficiency is 87.5%, and the energy efficiency is 80.1%.

example 3

[0054] High-purity machinable graphite pole plate is used as the current collector plate material, and the flow field is engraved on it. The entire collector plate is rectangular 200mm×240mm, the thickness of the collector plate is 4mm, and the depth of the channel groove is 1mm. The flow channels of the entire flow field are divided into two groups in parallel, and a total of four detours are made from the inlet to the outlet. There are ten runners from the inlet to the outlet and they are divided into five groups. The widths of the ten runners are 25mm, 25mm, 20mm, 20mm, 15mm, 15mm, 10mm, 10mm, 5mm, and 5mm. The charge-discharge coulombic efficiency of the single cell composed of the collector plate, the ion-exchange membrane and the graphite felt electrode is 91%, the voltage efficiency is 89.5%, and the energy efficiency is 81.4%.

[0055] From the above description, it can be seen that the present invention achieves the following technical effects:

[0056] The current c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com