Preparation method of compound amino acid injection

A compound amino acid and injection technology, which is applied in the field of preparation of compound amino acid injection, can solve problems such as oxygen isolation and poor solubility, decreased amino acid content, and yellowing of liquid color, and achieves easy operation by production personnel, low preparation temperature, The effect of short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

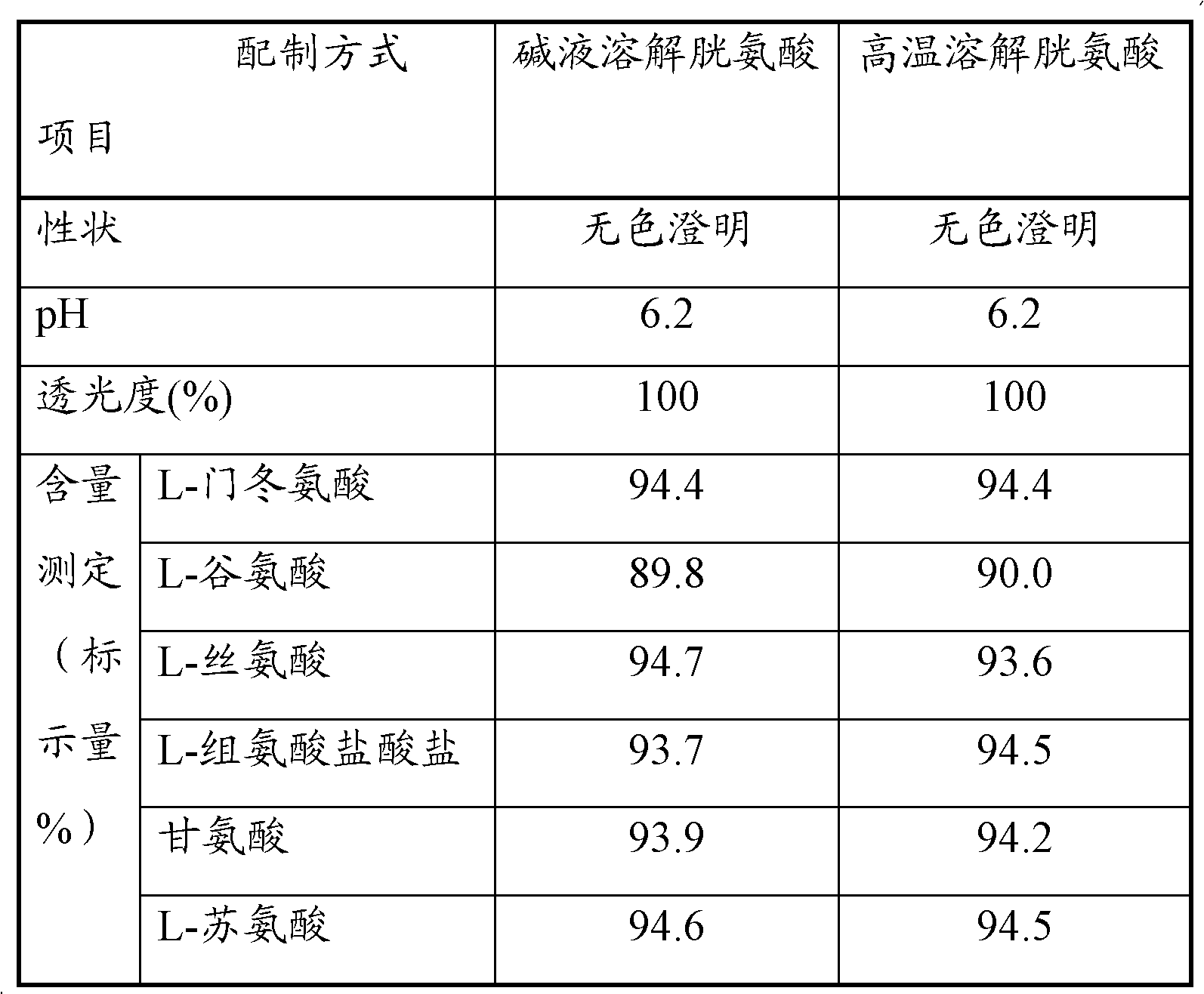

Examples

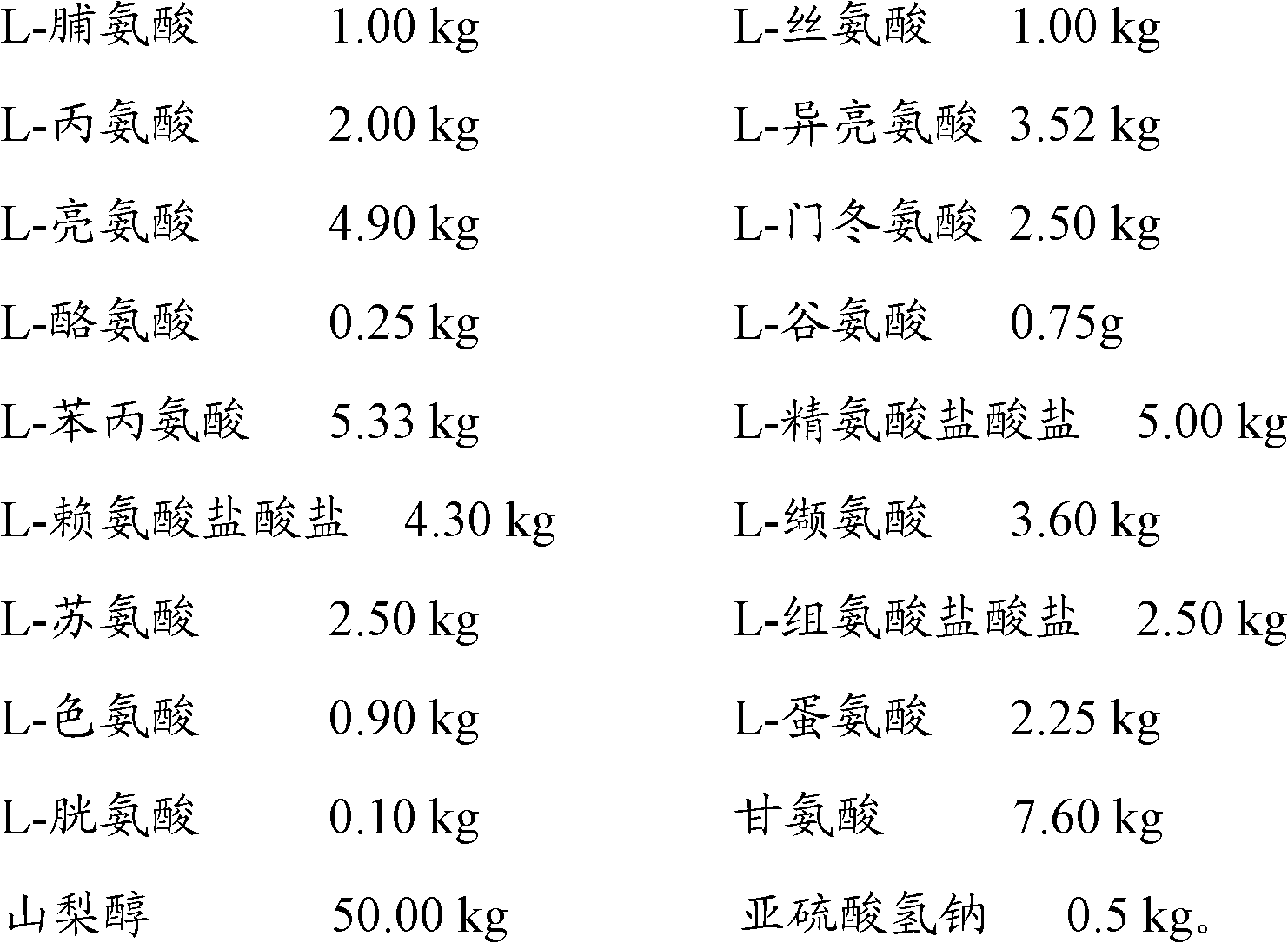

Embodiment 1

[0027] Follow the steps below to prepare compound amino acid injection:

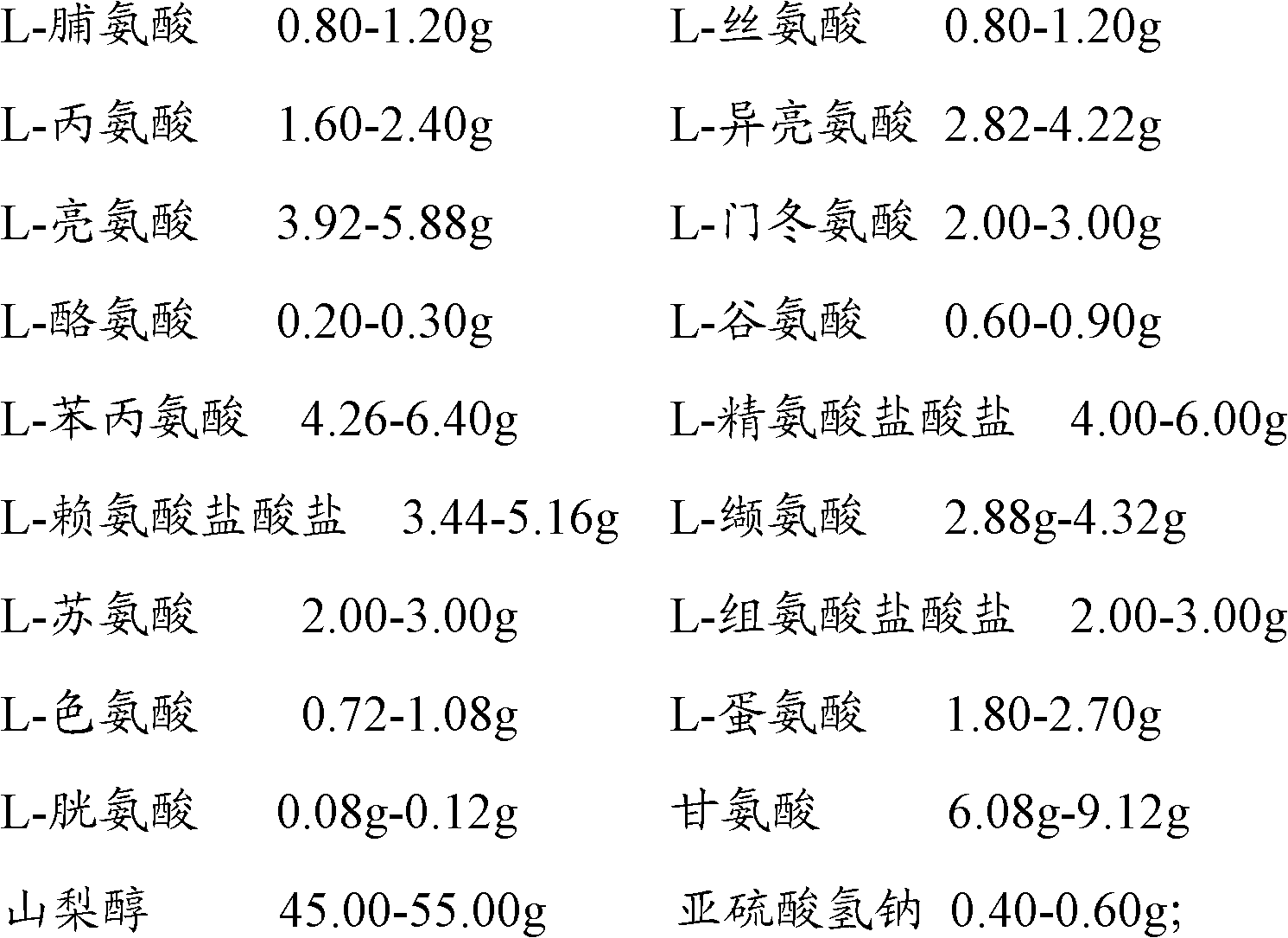

[0028] (1) Weigh the following components according to the formula quantity of each 1000ml compound amino acid injection mentioned above:

[0029]

[0030] (2) Turn on the vacuum pump and vacuumize the production equipment. The production equipment includes a preparation container and a pipeline system, until the vacuum degree reaches below -0.1MPa, fill nitrogen with a purity ≥ 99.9% to a positive pressure, and repeat the operation three times.

[0031] (3) Close the valve between the preparation container and the pipeline system, add 60% of the total amount of 65°C water for injection into the preparation container, and then vacuumize it until the vacuum degree reaches below -0.1MPa, and fill it with a purity ≥ 99.9% nitrogen to positive pressure, repeat the operation three times, under the condition of constantly filling the container with nitrogen to maintain the positive pressure, put into the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com