Method for removing incomplete thread by turning of numerically controlled lathe

A CNC lathe, a complete technology, applied in the field of removing incomplete threads, can solve the problems of high equipment maintenance costs, large one-time investment, and large physical exertion, so as to reduce labor intensity and processing costs, reduce handling, and improve processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

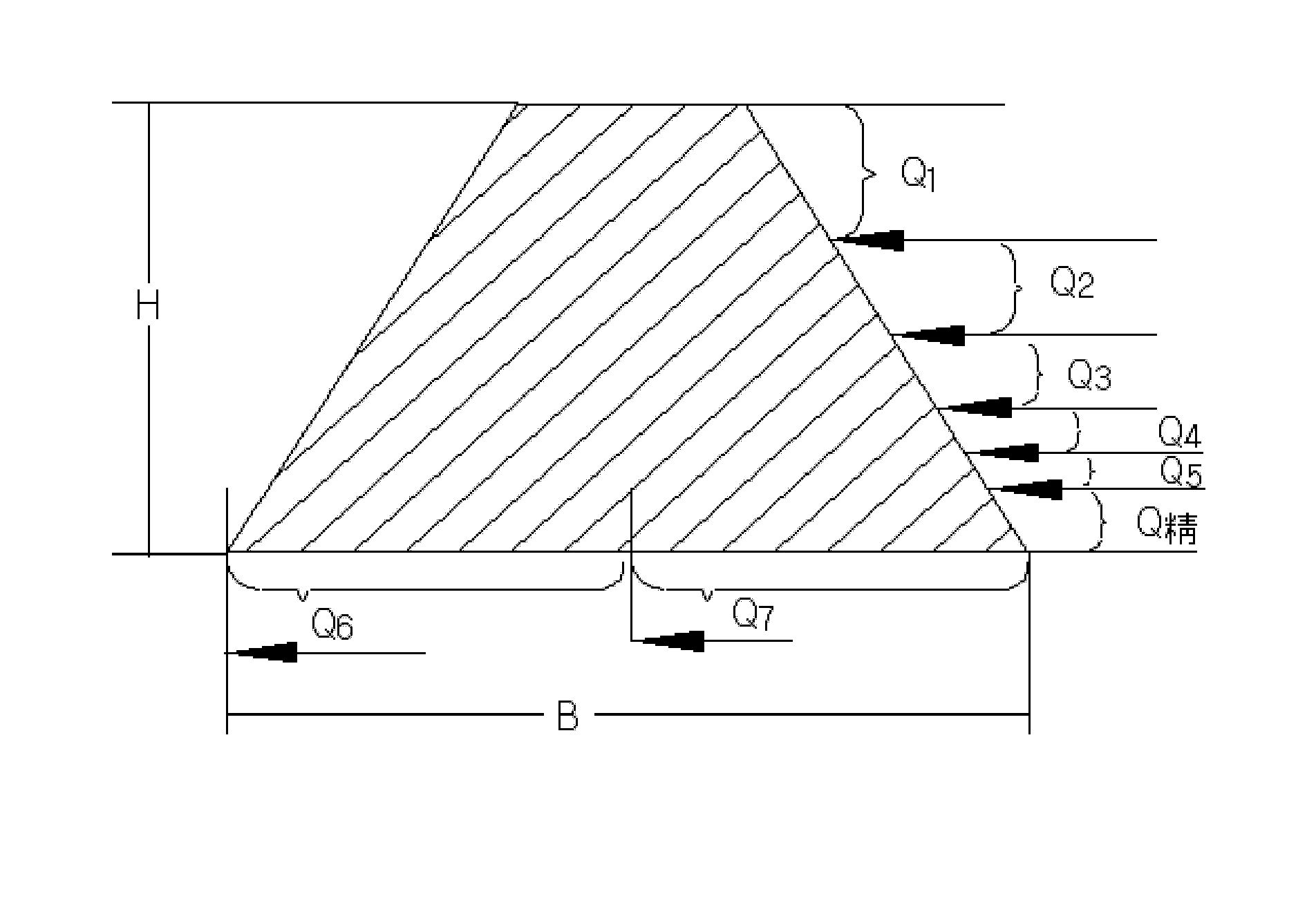

[0037] Remove the incomplete thread of the external thread, the parameters of the external thread are thread root diameter D=100mm, thread height H=3mm, pitch P=3mm, thread head length 6mm and thread root width B=3mm. The steps to remove the incomplete thread of the external thread by turning with CNC lathe are as follows:

[0038] a. Select the grooving knife: the grooving knife width is 2.5mm, the rake angle of the grooving knife tip is 20°, and it has a concave arc-shaped chip breaker, the blade elongation is 5mm, and the cutting edge is ground to Ra0.4.

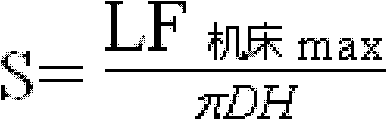

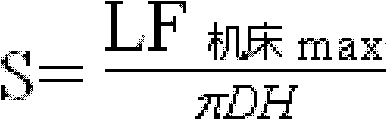

[0039] b. According to the thread cutting cycle command and the maximum cutting feed rate F set by the machine tool 机床max =5500mm / min, G01F5500 is used for tool retraction, and the spindle speed is calculated by the following formula:

[0040]

[0041] S = 6 * 5500 3.14 * 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com