Expandable high-melt-strength polypropylene resin and preparation method thereof

A technology of polypropylene resin and high melt strength, which is applied in the field of polymer materials, can solve problems such as environmental impact, and achieve the effect of high melt degree and good foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

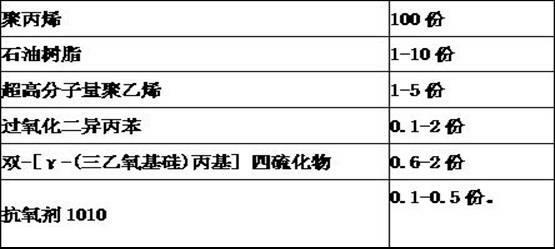

[0025] Example 1 Preparation of High Melt Strength Polypropylene Resin

[0026]

[0027] Method 1: Polypropylene, petroleum resin, ultra-high molecular weight polyethylene, dicumyl peroxide, bis-[γ-(triethoxysilyl)propyl]tetrasulfide, antioxidant Stir in the mixer at 900-1200 rpm and 60°C for 15 minutes, and then add it to the two-stage extruder: the first stage of the two-stage extruder is a parallel twin-screw extruder, and the long diameter of the extruder is The ratio is 40:1, the diameter of the screw is 75, the speed of the parallel twin-screw extruder is 100-400 rpm, and the temperature of the twin-screw extruder from the conveying section to the outlet is 190-210°C. The second stage is a single-screw extruder, the length-to-diameter ratio of the extruder is 15:1, the screw diameter is 150, the speed of the single-screw extruder is 25-50 rpm, the temperature of the extruder from the conveying section to the die It is granulated by reactive extrusion at 150-190°C to ...

Embodiment 2

[0030] Example 2 Preparation of High Melt Strength Polypropylene Resin

[0031]

[0032] Its preparation method is with embodiment one.

Embodiment 3

[0033] Preparation of Example Three High Melt Strength Polypropylene Resin

[0034] Change homopolypropylene into a mixture of homopolypropylene and copolymerized polypropylene, homopolypropylene accounts for 1-99% in the mixture, and the preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com