Automatic control device for prestressing force tensioning device

A technology of automatic control and tensioning device, applied in non-electric variable control, mechanical pressure/force control, control/regulation system, etc., can solve problems such as increasing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

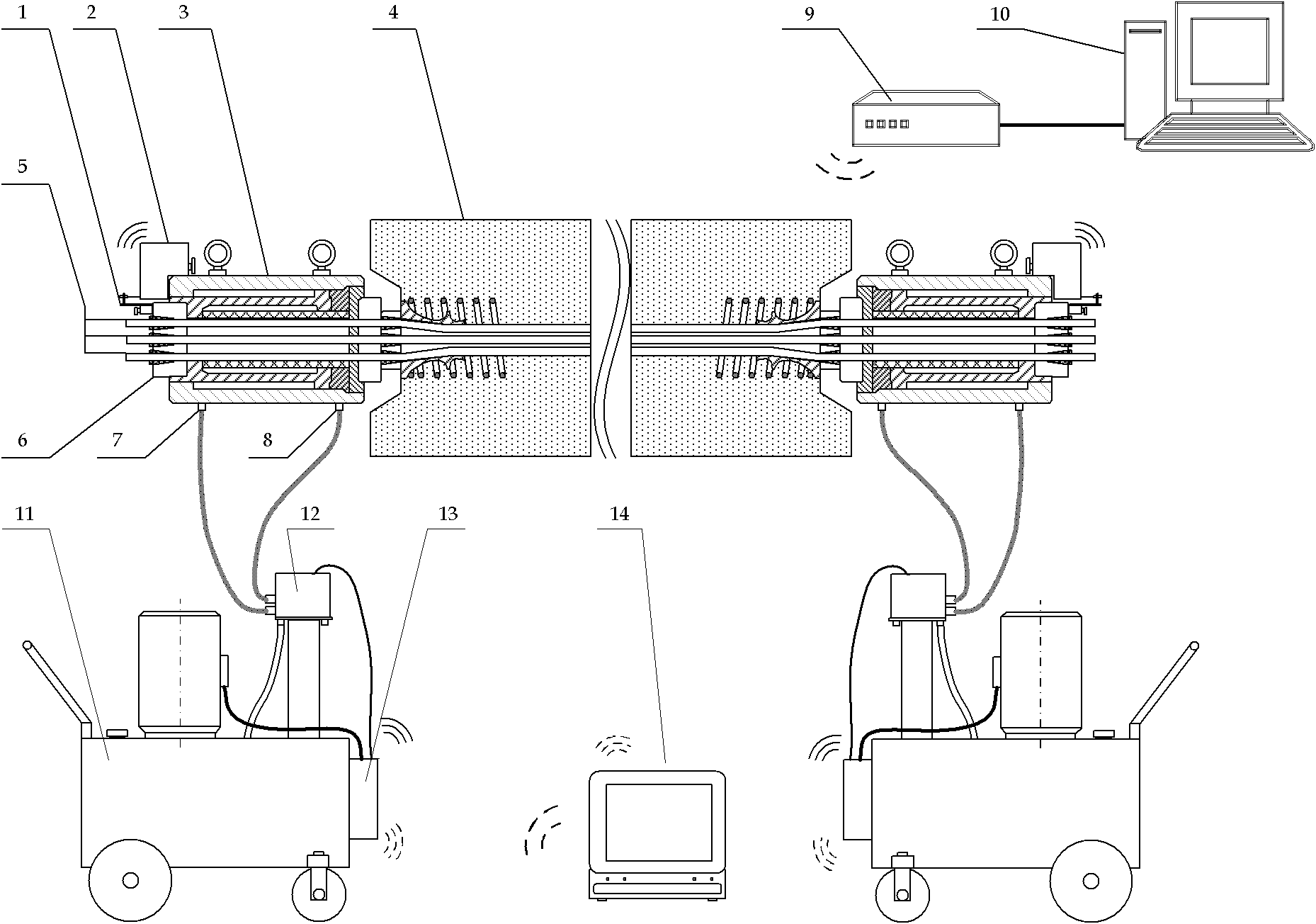

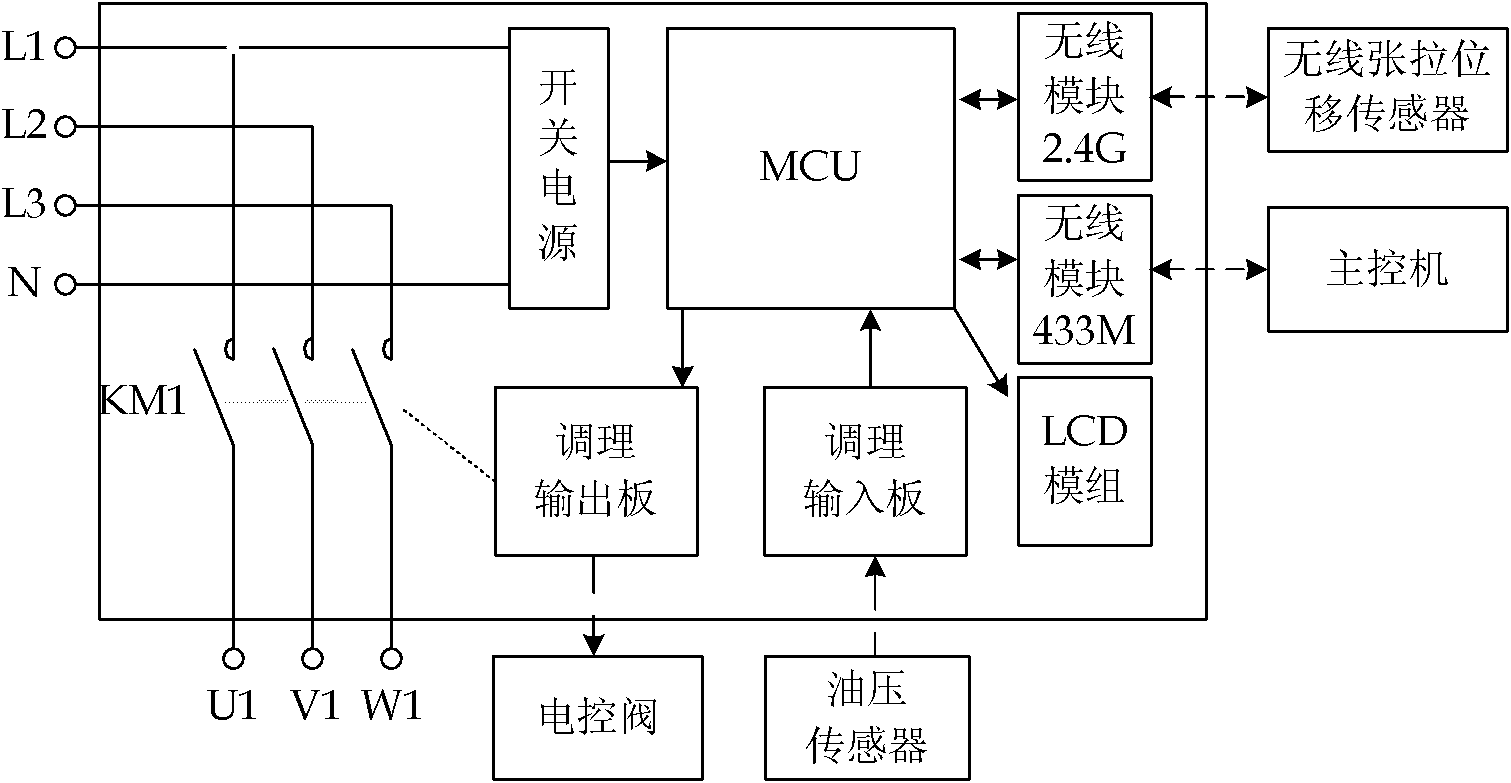

[0018] An automatic control device for a prestressed tensioning device, which includes a tool anchor 6, a hollow jack 3 matched with the tool anchor 6, and a hydraulic pump 11 connected to the oil inlet pipe 8 and the oil outlet pipe 7 at the lower part of the hollow jack 3 ,Such as figure 1 As shown: the upper side of the above-mentioned hollow jack 3 is equipped with a wireless tension displacement sensor 2, and the pump body of the hydraulic pump 11 is provided with a sub-controller 13 for controlling its electronically controlled valve group 12, and is also provided with a coordination unit. The host computer 14 and the remote web server 10 of tension endpoints.

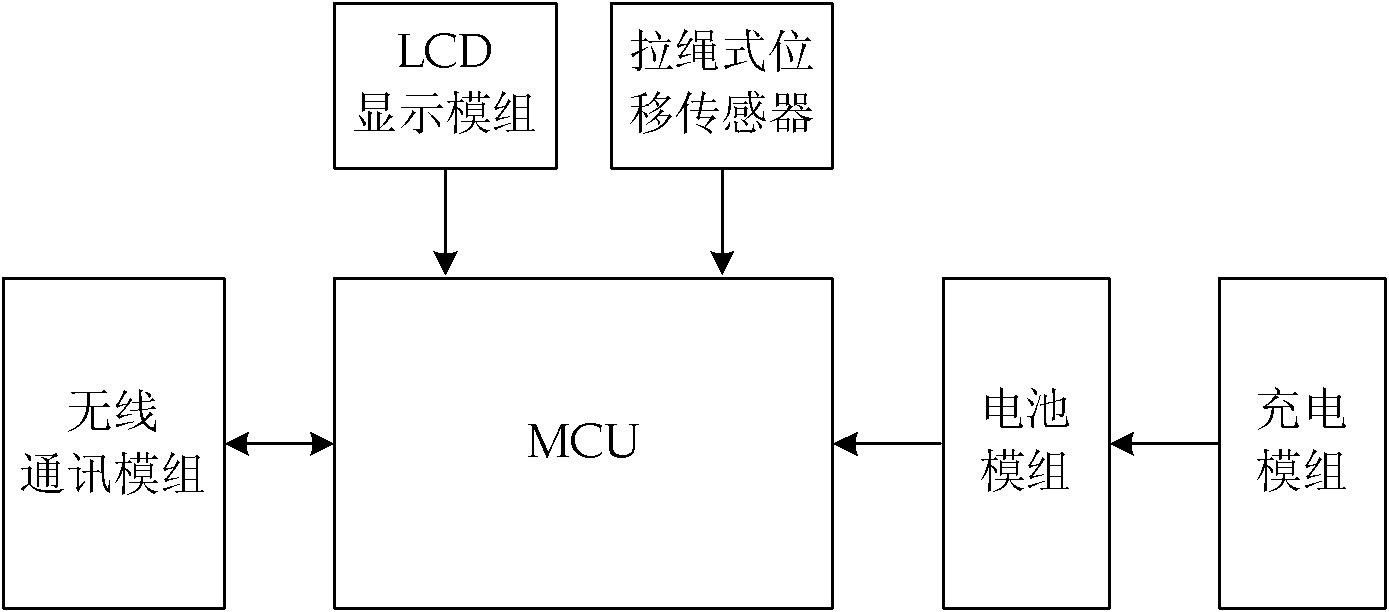

[0019] The above-mentioned wireless tension displacement sensor 2 includes a housing, and the interior of the housing is assembled from a single-chip microcomputer main control board and a drawstring displacement sensor from top to bottom, and a lithium battery is installed on one side of the drawstring displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com