Paper-based friction plate and manufacturing method thereof

A paper-based friction lining and friction performance technology, which is applied to friction linings, chemical instruments and methods, mechanical equipment, etc., can solve problems such as large dynamic/static friction coefficient ratio, low dynamic friction coefficient, and inconsistent development direction of friction linings for environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

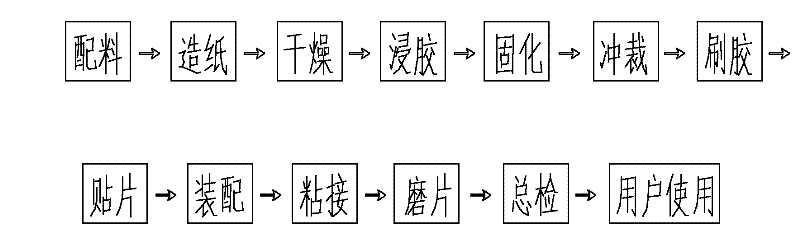

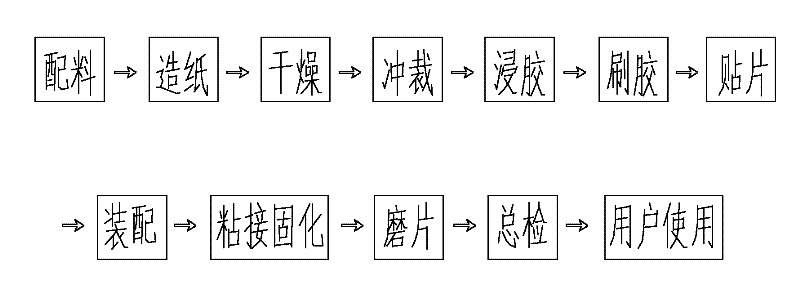

Method used

Image

Examples

Embodiment 1

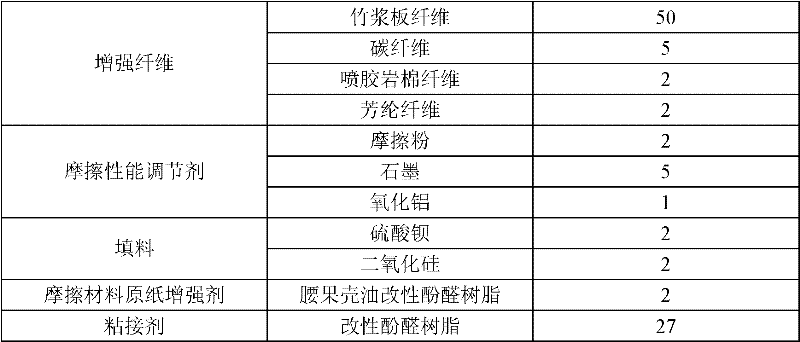

[0034] The raw material formula of the paper-based friction sheet is as follows:

[0035] Table 1 Embodiment 1 formula (unit: %)

[0036]

[0037] During the implementation process, the experimental parameters of each step are taken from the following table data:

[0038] Table 2 Example 1 Experimental Parameters

[0039]

Embodiment 2

[0041] The raw material formula of the paper-based friction sheet is as follows:

[0042] Table 3 Embodiment 2 formula (unit: %)

[0043]

[0044] During the implementation process, the experimental parameters of each step are taken from the following table data:

[0045] Table 4 Example 2 Experimental Parameters

[0046]

[0047]

Embodiment 3

[0049] The raw material formula of the paper-based friction sheet is as follows:

[0050] Table 5 Embodiment 3 formula (unit: %)

[0051]

[0052] During the implementation process, the experimental parameters of each step are taken from the following table data:

[0053] Table 6 embodiment 3 experimental parameters

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com