Leakage detecting protection circuit capable of periodically automatically detecting function integrity

A leakage detection and protection circuit technology, which is applied in the direction of automatically disconnected emergency protection devices, emergency protection circuit devices, and measuring power, can solve the problems of not being able to automatically detect whether the leakage protection function is intact, and achieve low cost, convenient use, and responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

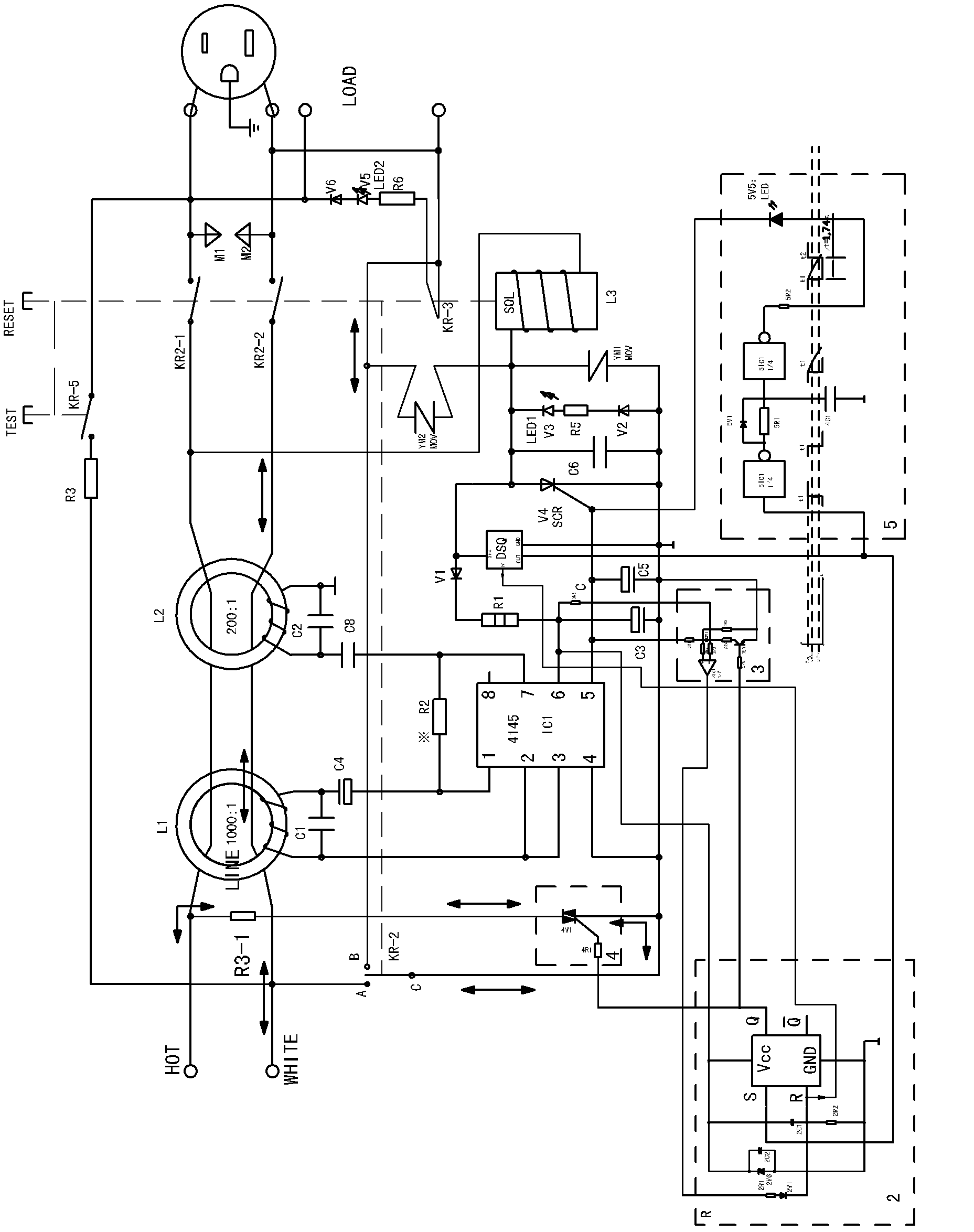

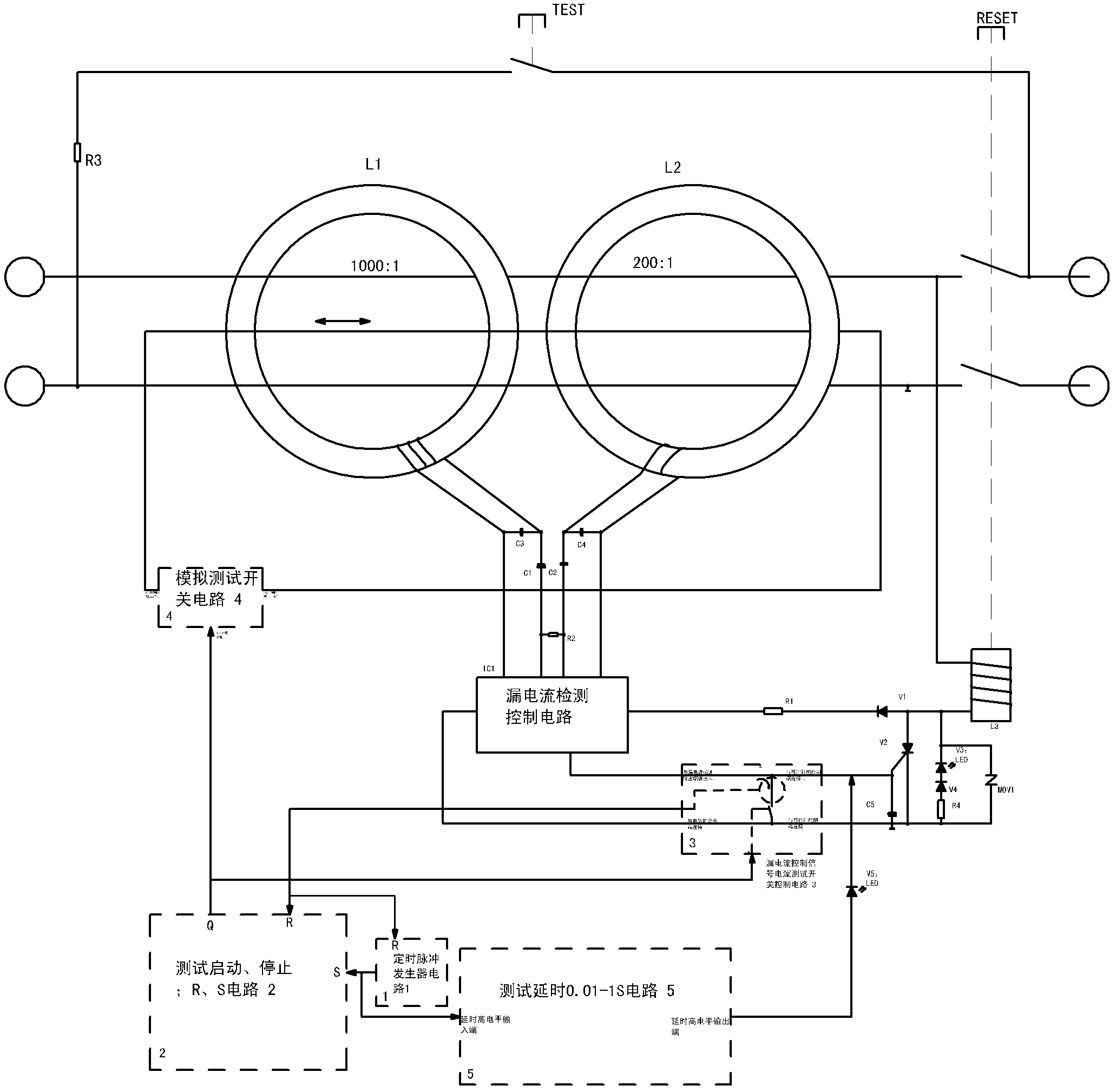

[0047]refer to figure 1 and figure 2 , Leakage detection protection circuit that can automatically detect functional integrity at regular intervals, including main circuit switches KR2-1, KR2-2, reset button RESET, tripping coil L3 that can cooperate with the mechanical structure to disconnect the main circuit switch, and control tripping coil The thyristor V4 for switching on and off the power supply circuit, the induction coil L1 for detecting leakage current, the self-induction coil L2 for detecting low-resistance faults, and the control chip IC1 for driving the thyristor on and off through the detection result of leakage current, also includes a) Timer DSQ for regularly outputting the functional integrity detection signal; b) Detection signal latch circuit 2; c) Analog test switch 4 for generating simulated leakage current; d) Delayed output circuit 5; e) Used for intercepting The sampling circuit 3 that controls the output current of the chip; the timer outputs the dete...

Embodiment 2

[0060] refer to Figure 19 , the leakage detection and protection circuit of this embodiment is also provided with a SPDT analog power supply switch KR-2 linked with the reset button, but its structure is different, its first static contact terminal A is connected to one of the power supply input terminals, Its second static contact terminal B is connected to the corresponding power supply output terminal, and its moving contact rod C is connected to another power supply input terminal passing through the end of the self-induction coil L2 for detecting low-resistance faults; when the reset button is in the tripping state , the moving contact rod C of the analog power supply switch KR-2 is connected to the second static contact terminal B, and the analog power supply switch KR-2 is in a closed state; when the reset button is pressed, the moving contact rod C of the analog power supply switch KR-2 Disconnect from the second static contact terminal B, and automatically disconnect...

Embodiment 3

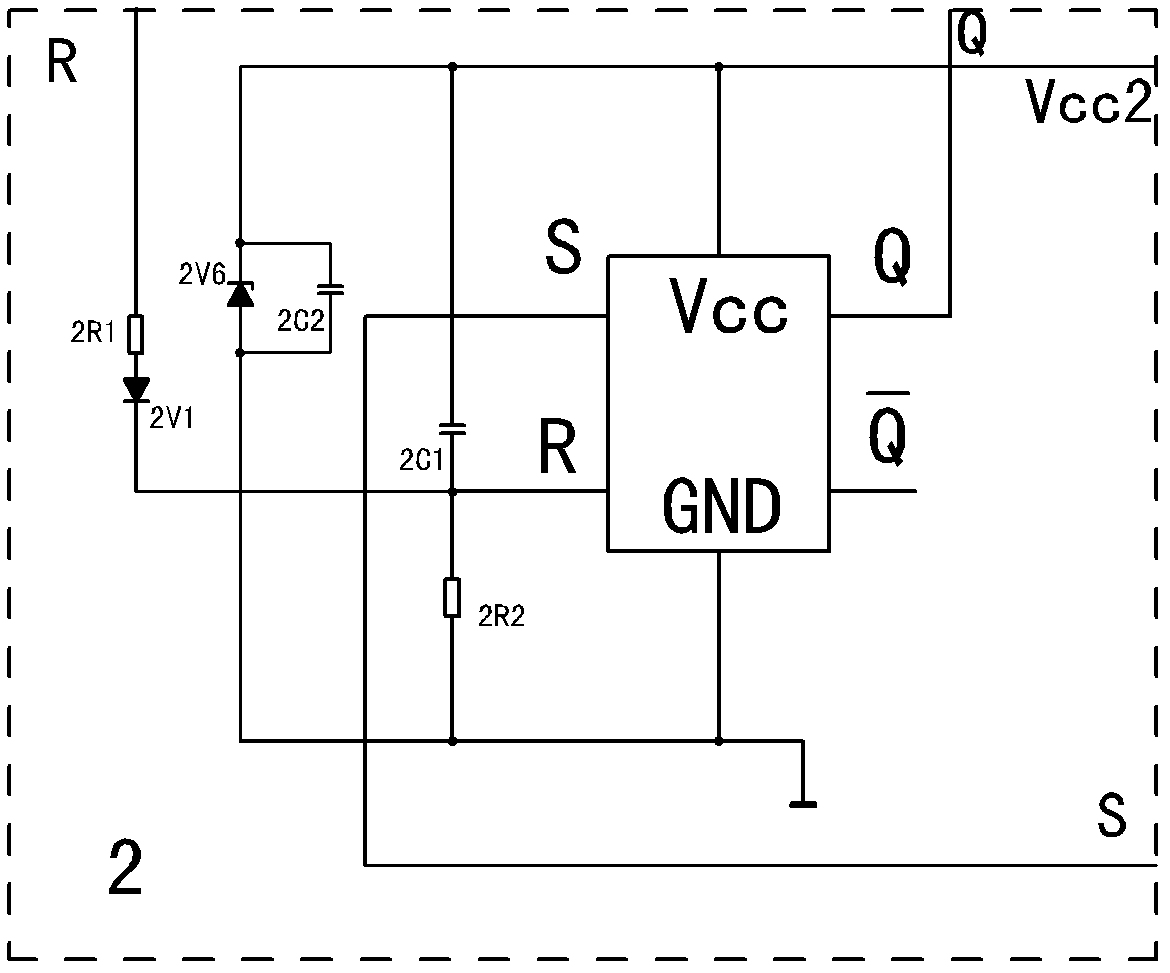

[0065] refer to Figure 20 , the latch circuit 2 of this embodiment is composed of an RS flip-flop integrated chip and peripheral circuits; the sampling circuit 3 is composed of a comparator and an electronic switch 3V3, and the triode used in the electronic switch here (if the required drive current is small, it can also be used FET); the triac V4 used in the analog detection switch 4; the combination of an inverter and a discharge circuit used in the delay output circuit 5.

[0066] The moving contact rod C of the analog power supply switch KR-2 in this embodiment is connected to the neutral line at the rear end of the main circuit neutral switch KR2-2 through the tripping coil L3 and the piezoresistor YM2 (that is, the neutral line at the output terminal), and the static contact terminal B is connected to the HOT terminal of the power input live wire, and the static contact terminal A is connected to the HOT tap of the live wire passing through the self-excited coil L2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com