Dotting machine for numerical control flat plate

A technology of spot holes and plates, applied in workshop equipment, manufacturing tools, etc., can solve the problems of inability to process large plate workpieces and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described in detail in conjunction with the following examples.

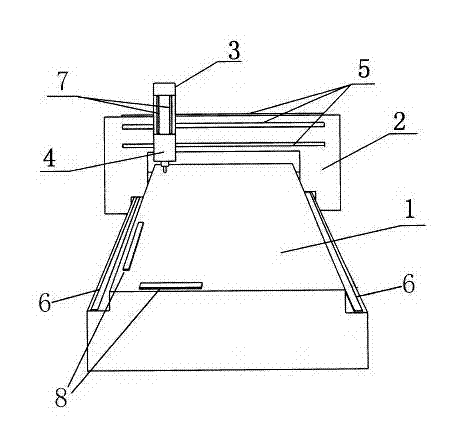

[0028] A kind of numerically controlled flat board punching machine of the present invention such as figure 1 as shown, figure 1 It is the host machine of a kind of numerically controlled plate punching machine of the present invention, which adopts an external computer control device (the externally connected known common equipment, its schematic diagram is omitted). Among them: a rectangular workbench 1 for placing flat panels is provided, and a workbench guide rail 6 parallel to the work surface of the rectangular workbench 1 is provided on a pair of opposite sides of the rectangular workbench 1; a gantry frame 2, a gantry The frame 2 is connected with the rectangular workbench 1 through the workbench guide rail 6, the gantry frame 2 can move along the workbench guide rail 6, and the beam of the gantry frame 2 is provided with a gantry guide rail 5 parallel to the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com