Production process for a microneedle arrangement and corresponding microneedle arrangement and use

A manufacturing method and technology of microneedles, applied in the direction of microstructure devices, manufacturing microstructure devices, microelectronic microstructure devices, etc., can solve the problems of cost increase and achieve the effect of improving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the figures, identical reference numbers designate identical or functionally identical components.

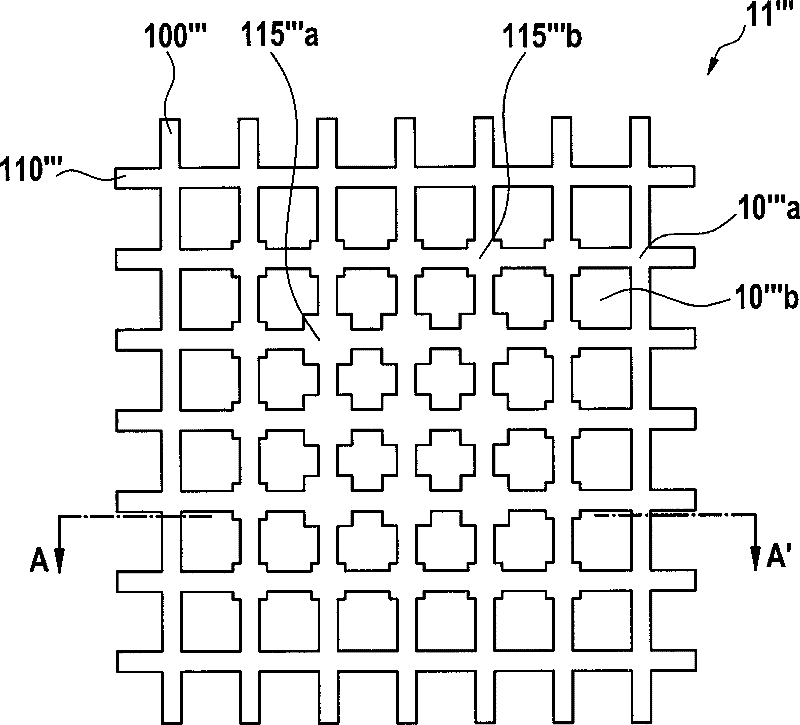

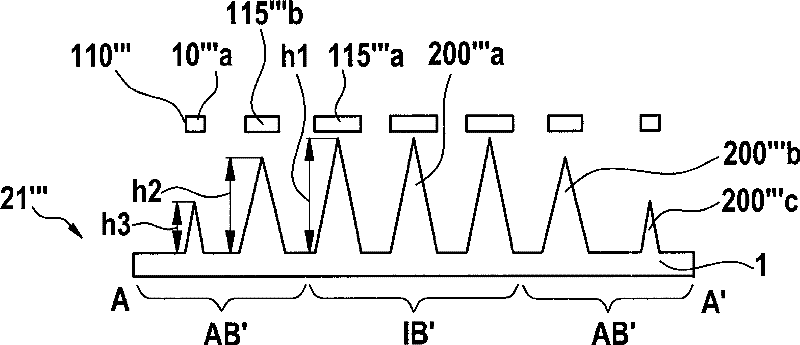

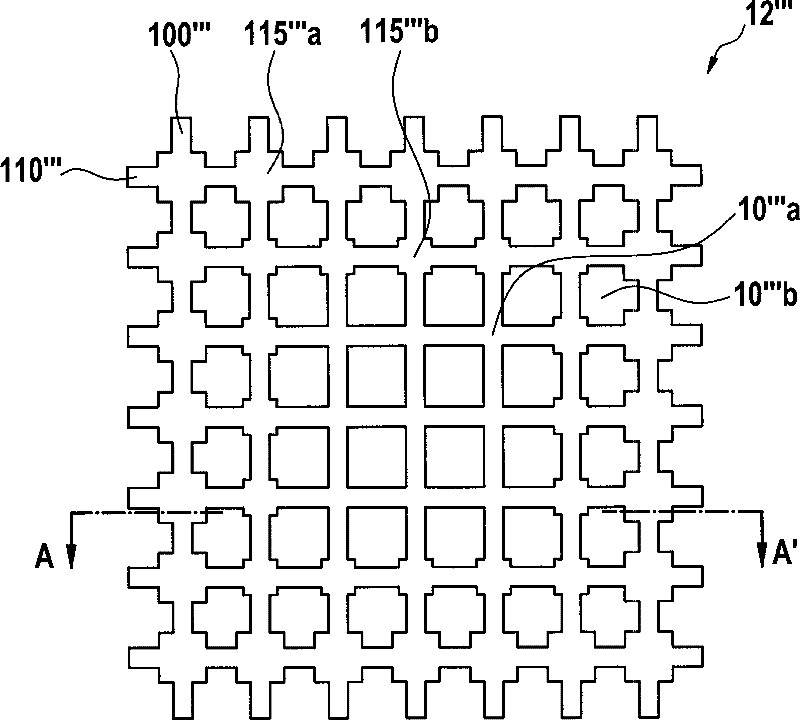

[0033] Figure 1a , b are schematic diagrams for explaining the first embodiment of the manufacturing method of the microneedle device according to the present invention, specifically, Figure 1a For the top view of the etched grid, Figure 1b for the etched grid and the resulting microneedle device along the Figure 1a A cross-sectional view of line A-A'.

[0034] The reference numeral 10' designates an etching mask in the first embodiment. This etch mask is as Figure 8a The etch mask 10 of , b has a regular orthogonal grid composed of horizontal grid tabs 100' and vertical grid supports 110'. The grid intersection areas are indicated with reference numeral 10'a and the grid openings with reference numeral 10'b.

[0035] In contrast to the above-described etch mask 10, this etch mask 10' has a square reinforcement area 115' in the grid intersection area 10'a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com