Device for ultrasonic atomization and concentration of ethanol and method for concentrating ethanol

A technology of ultrasonic atomization and ethanol, which is applied in the direction of injection device, liquid injection device, separation/purification of hydroxyl compounds, etc., can solve the problems of low power efficiency of blower equipment, unfavorable capture, coagulation, consumption of transmission energy, etc., to achieve Avoid power consumption, simple device, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

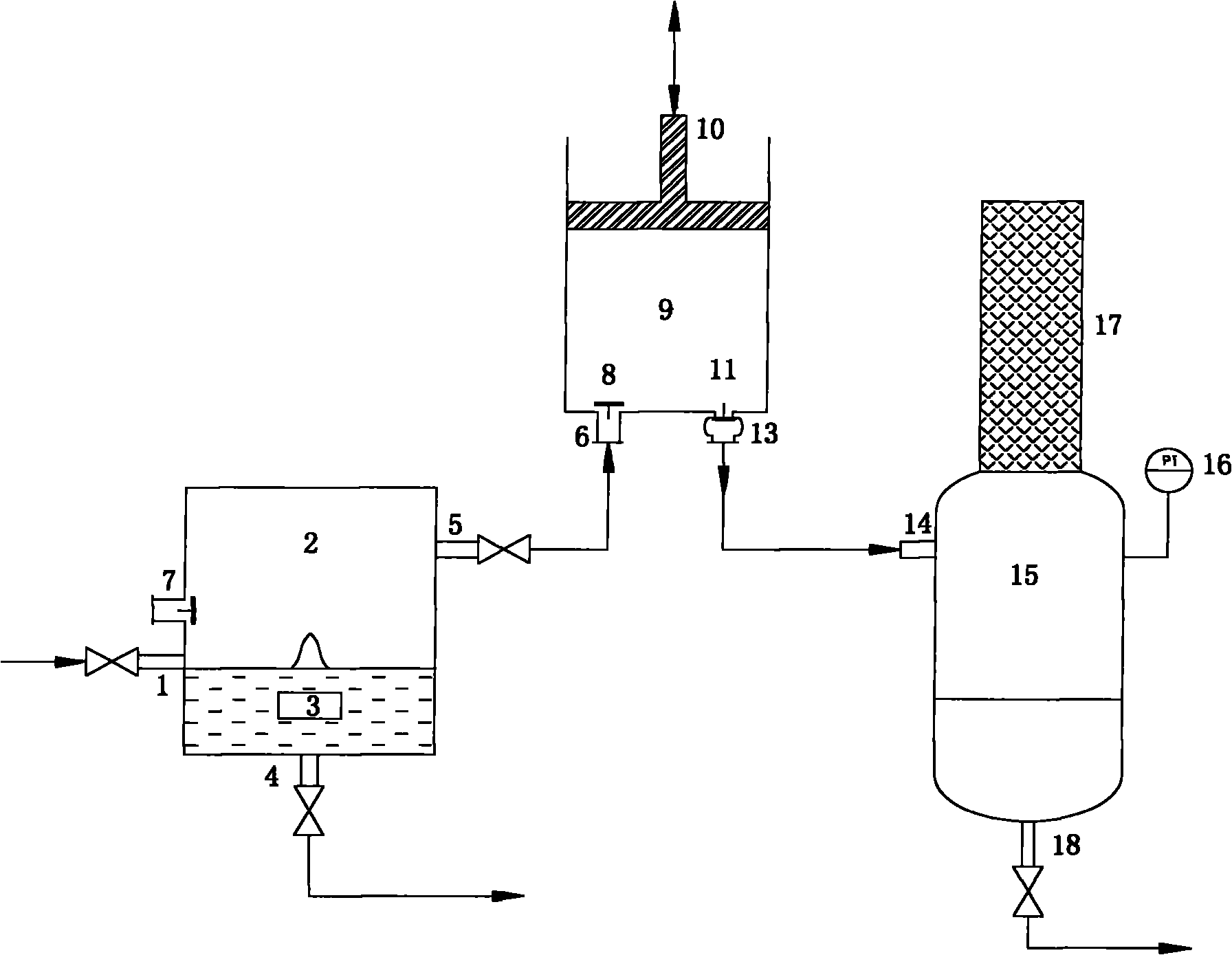

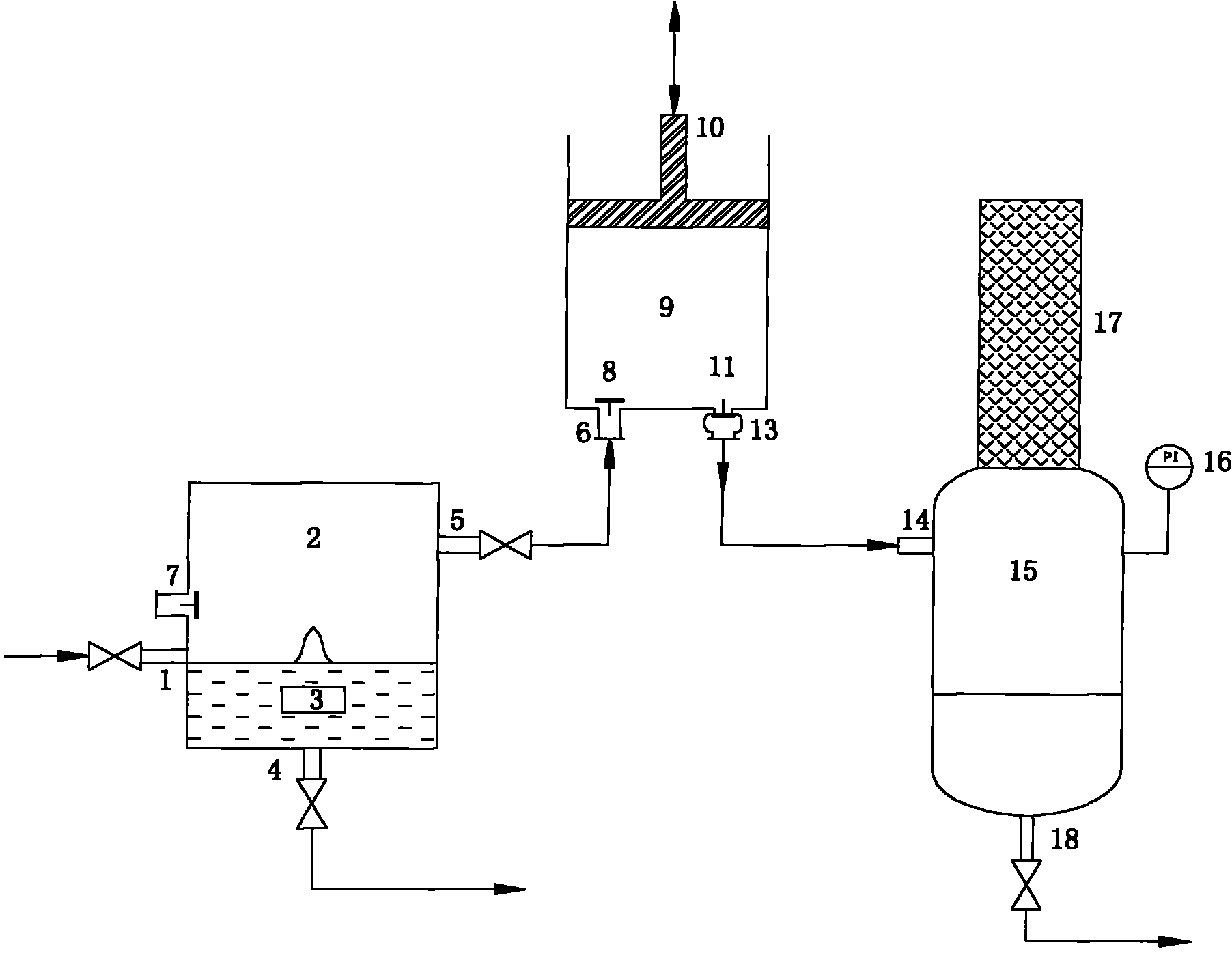

[0016] The detailed structure and operation method of a device of the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the concentrator of the device of the present invention includes: a processing tank 9 , a piston 10 , a suction check valve 8 , and an exhaust check valve 11 . When the piston 10 moves upward, the suction one-way valve 8 is opened, the exhaust one-way valve 11 is closed, and the mist in the ultrasonic atomization tank 2 enters the treatment tank 9; when the piston moves downward, the suction one-way valve 8 is closed , the mist in the treatment tank 9 is compressed and liquefied, and the exhaust check valve 11 is opened and discharged into the collection tank. The suction one-way valve and exhaust one-way valve use spring-controlled mechanical one-way valves, and the opening pressure value of the one-way valves can be specifically determined according to needs.

[0018] The method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com