Production method of gardenia yellow pigment

A gardenia yellow pigment and a production method technology, applied in the production field of gardenia yellow pigment, can solve the problems of high color price, limited application range, low OD value, etc., and achieve high purity, expanded application range and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

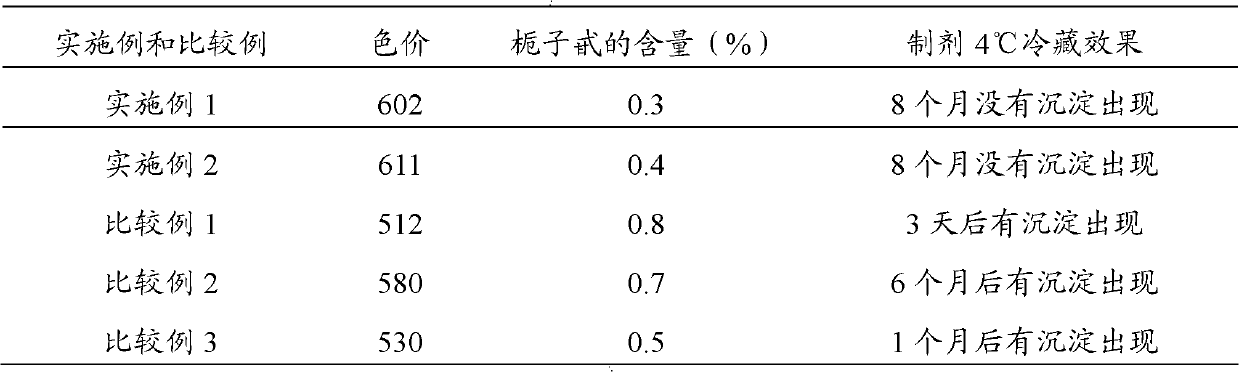

Examples

Embodiment 1

[0054] Grind the jasmine fruit, take 5000kg of the jasmine fruit powder and send it into a horizontal extractor with a rotating speed of 4.5h / r by the feeding auger, spray an 80% ethanol aqueous solution at 35°C for leaching, Obtain the extract solution, and then vacuum-concentrate the extract solution at 80° C. under a vacuum degree of -0.08 MPa to obtain 1900 kg of the first pigment solution;

[0055] Put the obtained first pigment solution on the HP-10 type macroporous adsorption resin column, wash the column with deionized water with 2 times the volume of the resin after adsorption saturation, and then wash with 4 times the volume of the resin and 25% ethanol aqueous solution Column, finally use 2 times the volume of resin and 80% by volume ethanol aqueous solution to elute the gardenia yellow pigment, and carry out vacuum concentration at 80°C with the eluate containing gardenia yellow pigment at a vacuum degree of -0.08MPa , obtain the second pigment solution of 330kg; ...

Embodiment 2

[0062] Grind the gardenia fruit, take 8000kg gardenia fruit powder and send it into a horizontal extractor with a rotating speed of 4.5h / r from the feeding auger, spray an ethanol aqueous solution with a volume percentage of 80% at 35°C for extraction, Obtain the extract solution, and then vacuum-concentrate the extract solution at 80° C. under a vacuum degree of -0.08 MPa to obtain 3500 kg of the first pigment solution;

[0063] Put the obtained first pigment solution on the HP-10 type macroporous adsorption resin column, wash the column with deionized water with 2 times the volume of the resin after adsorption saturation, and then wash with 4 times the volume of the resin and 25% ethanol aqueous solution Column, finally use 2 times the volume of resin and 80% by volume ethanol aqueous solution to elute the gardenia yellow pigment, and carry out vacuum concentration at 80°C with the eluate containing gardenia yellow pigment at a vacuum degree of -0.08MPa , obtain the second p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com