Reduced-pressure flash tank and reduced-pressure distillation method

A vacuum distillation tower and flash tank technology, applied in vacuum distillation, vacuum distillation, distillation in a rotating container, etc., can solve problems such as the limited function of the flash tower, and is beneficial to capacity expansion, improvement of evaporation rate, The effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

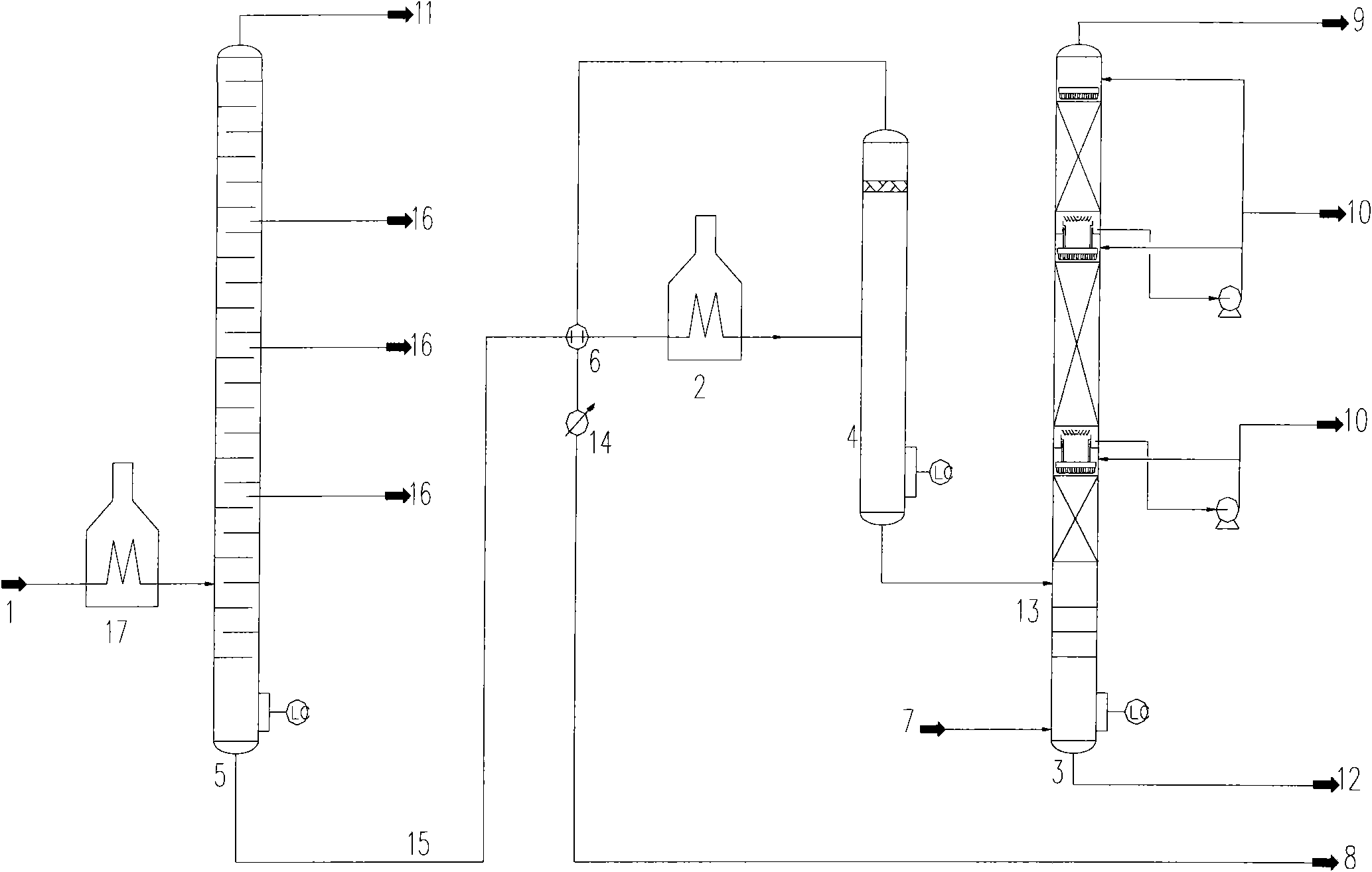

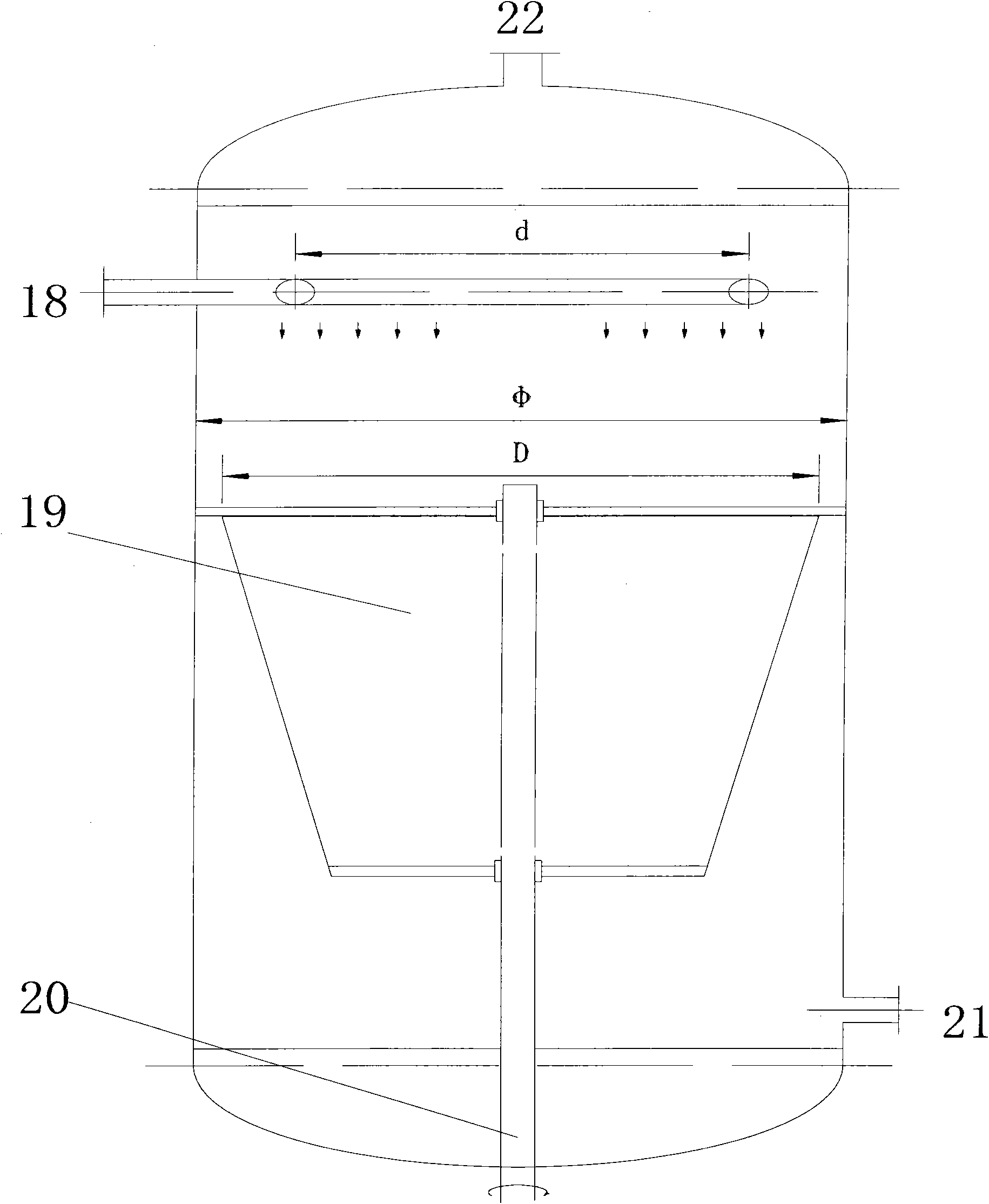

[0034] combined with figure 1 , a kind of technical process of the method of the present invention is: after pretreatment crude oil 1 is heated up to 360 ℃~370 ℃ through atmospheric heating furnace 17, enters atmospheric distillation tower 5, and distills off constant top product 11 and each side stream atmospheric distillate oil 16 . Atmospheric residue 15 and flash top gas heat exchange and heat up, enter the decompression furnace 2 to heat to 380 ° C ~ 400 ° C, and enter the decompression flash tank gas-liquid separator 18 into the decompression flash tank for preliminary gas-liquid separation . The gas phase rises and is discharged from the flash top gas outlet 22 on the top of the tank. After the constant bottom oil / flash top gas 6 heat exchange-flash top gas condenser 14 is condensed, the gas-liquid separation is carried out, and the separated liquid phase is used as the flash top product 8 , the gas phase is connected to the vacuum system to control the residual press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com