Method for producing beer with low purine content from malt roots, and product

A technology of beer and purine, which is applied in the direction of beer brewing, etc., can solve the problems of affecting the taste of beer, wasting resources, reducing the content of barley malt, etc., and achieve the effects of ensuring personal health, improving utilization rate, and reducing low purine substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Malt peeling and germ removal: the moisture content of the malt used is controlled at 0.4~0.6%, the seed coat of the malt is removed by a peeling machine, the malt is vigorously stirred by a blower to separate the germ from the malt, and the germ and seed are removed by a grain separator Skin;

[0031] (2) Pulverization: the malt dehulled and degerminated obtained in step (1) is dry pulverized by a double-roller mill to obtain malt powder, the roller spacing of the double-roller mill is adjusted to 0.30mm, and the pulverized malt powder is passed through a 60-mesh sieve;

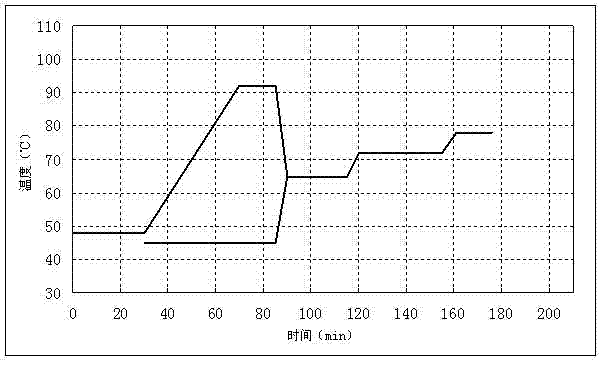

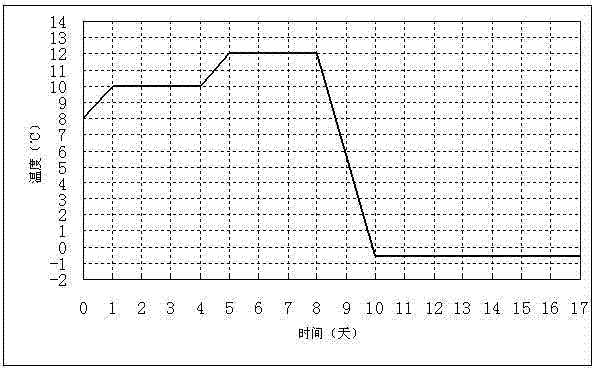

[0032] (3) Wort saccharification stage: the raw materials in the saccharification stage are composed of 60% main material and 40% auxiliary material by weight percentage, the main material is the malt powder obtained in step (2), and the auxiliary material is corn starch; the auxiliary material and water are added according to each gram of auxiliary material Mix evenly with 3.9ml of water, pump to...

Embodiment 2

[0037] (1) Malt peeling and germ removal: the moisture content of the malt used is controlled at 0.4~0.6%, the seed coat of the malt is removed by a peeling machine, the malt is vigorously stirred by a blower to separate the germ from the malt, and the germ and seed are removed by a grain separator Skin;

[0038](2) Pulverization: the malt dehulled and degerminated obtained in step (1) is dry pulverized with a double-roller pulverizer to obtain malt powder, the distance between the rollers of the double-roller pulverizer is adjusted to 0.35mm, and the pulverized malt powder is passed through a 60-mesh sieve;

[0039] (3) Wort saccharification stage: The raw materials in the saccharification stage are composed of 65% main material and 35% auxiliary material by weight percentage. The main material is the malt powder obtained in step (2), and the auxiliary material is corn starch; Mix evenly with 4.2ml of water, pump to the gelatinization pot, feed at 51°C, raise the temperature ...

Embodiment 3

[0044] (1) Malt peeling and germ removal: the moisture content of the malt used is controlled at 0.4~0.6%, the seed coat of the malt is removed by a peeling machine, the malt is vigorously stirred by a blower to separate the germ from the malt, and the germ and seed are removed by a grain separator Skin;

[0045] (2) Pulverization: The dehulled and degerminated malt obtained in step (1) is dry pulverized by a double-roller pulverizer to obtain malt powder, the distance between the rollers of the double-roller pulverizer is adjusted to 0.32mm, and the pulverized malt powder is passed through a 60-mesh sieve;

[0046] (3) Wort saccharification stage: the raw materials in the saccharification stage are composed of 60% main material and 40% auxiliary material by weight percentage, the main material is the malt powder obtained in step (2), and the auxiliary material is corn starch; the auxiliary material and water are added according to each gram of auxiliary material Mix evenly wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com