Automatic welding method for aluminum alloy sheet

A welding method and automatic welding technology, applied in the field of aluminum alloy welding, can solve the problems of unstable welding, low welding efficiency of equipment, and poor welding quality, and achieve the effect of improving the qualification rate and ensuring the welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

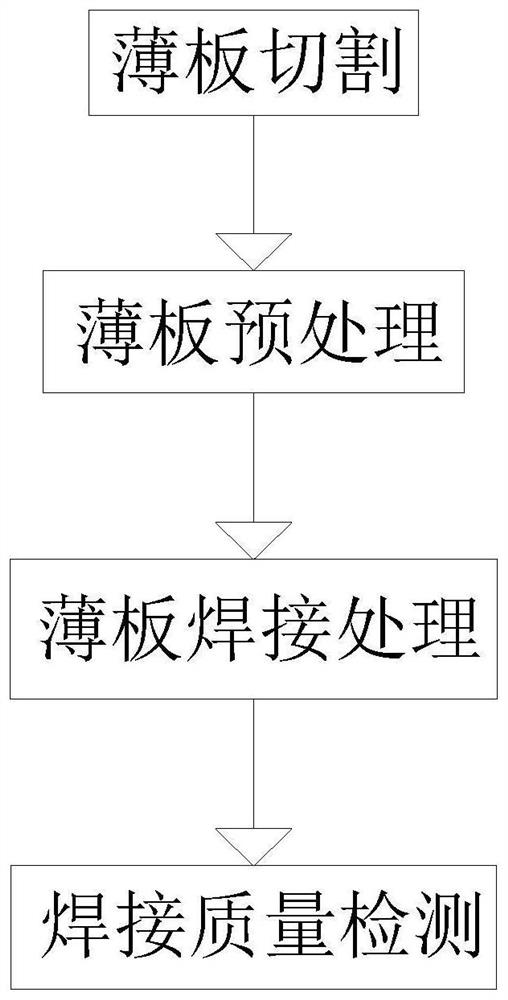

[0041] like Figure 1-8 As shown, the present invention provides an automatic welding method for an aluminum alloy sheet, and the automatic welding method for an aluminum alloy sheet includes the following steps:

[0042] Step 1: Thin plate cutting;

[0043] Step 2: Pretreatment of thin plate;

[0044] Step 3: Sheet welding treatment;

[0045] Step 4: Welding quality inspection.

[0046]The first step includes: measuring the size to be cut on the thin plate with a measuring ruler, then marking the surface of the thin plate with a marker, placing the thin plate on the cutting machine, using the cutting machine to cut the thin plate, and cutting the thin plate into specified length.

[0047] The second step includes the following steps:

[0048] S1: Place the cut sheet on the grinding equipment, start the grinding equipment to grind the raised points on the surface of the sheet, and grind and remove the residue attached to the surface of the sheet;

[0049] S2: Place the p...

Embodiment 2

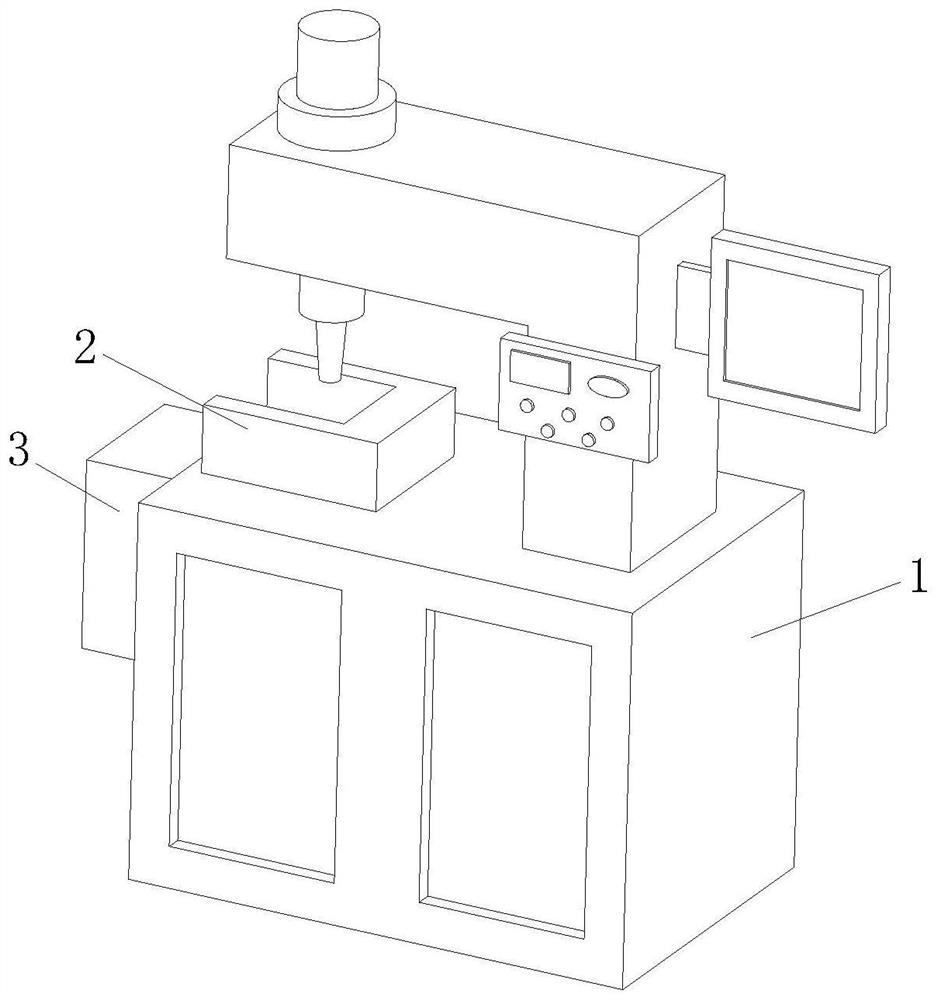

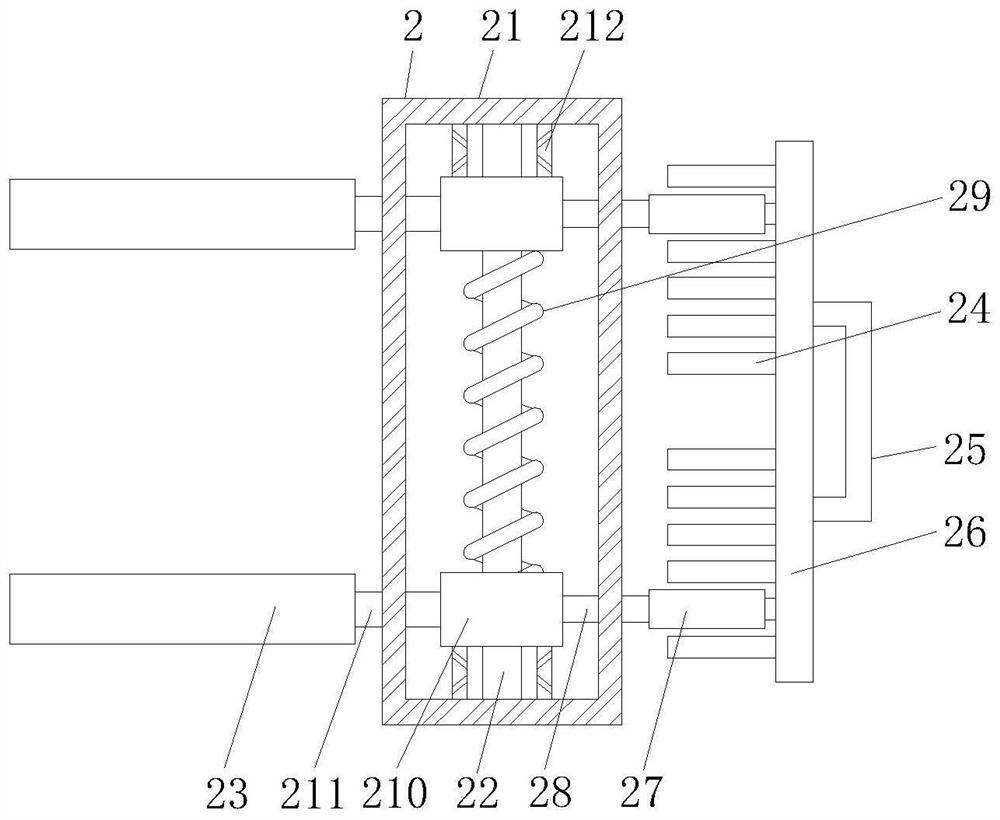

[0054] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the welding equipment includes a welding machine body 1, a positioning mechanism 2 is provided on the worktable surface of the welding machine body 1, and the positioning mechanism 2 includes a positioning box 21. The inner cavity of the positioning box 21 is provided with a guide rod 22, the surface of the guide rod 22 is slidably connected with a slider 210, one side of the slider 210 is fixedly connected with a transmission rod 211, and one end of the transmission rod 211 extends to the end of the positioning box 21. A splint 23 is fixedly connected to the outside, and a straight rod 28 is fixedly connected to the other side of the slider 210. One end of the straight rod 28 extends to the outside of the positioning box 21 and is fixedly connected with a sleeve plate 27. The positioning mechanism 2 also includes a positioning plate 26 One side of t...

Embodiment 3

[0057] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a dust removal mechanism 3 is provided on the side of the welding machine body 1, and the dust removal mechanism 3 includes a water tank 31, and the water tank 31 is provided with a purification liquid, and the water tank A suction pump 38 is fixedly connected to one side of the top surface of the suction pump 31. The input end of the suction pump 38 is fixedly connected to a dust hood 32. The output end of the suction pump 38 is fixedly connected to a conduit 33, and the bottom end of the conduit 33 extends to the water tank. The inner cavity of 31 is fixedly connected with a dispersion block 37. The top of the inner cavity of the dispersion block 37 is provided with a fixing groove 371. The fixing groove 371 is communicated with the conduit 33. The bottom surface of the fixing groove 371 is provided with a dispersion groove 372. The bottom end is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com