Production method and equipment for double-sided adhesive waterproof coiled material of macromolecular tire

A technology of waterproof membrane and production method, which is applied in the direction of layered products, chemical instruments and methods, textiles and papermaking, etc. It can solve the problems of affecting the normal operation of production equipment, inconvenient use and maintenance, and high viscosity of modified asphalt, and achieves improvement. The effect of product quality, cost saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

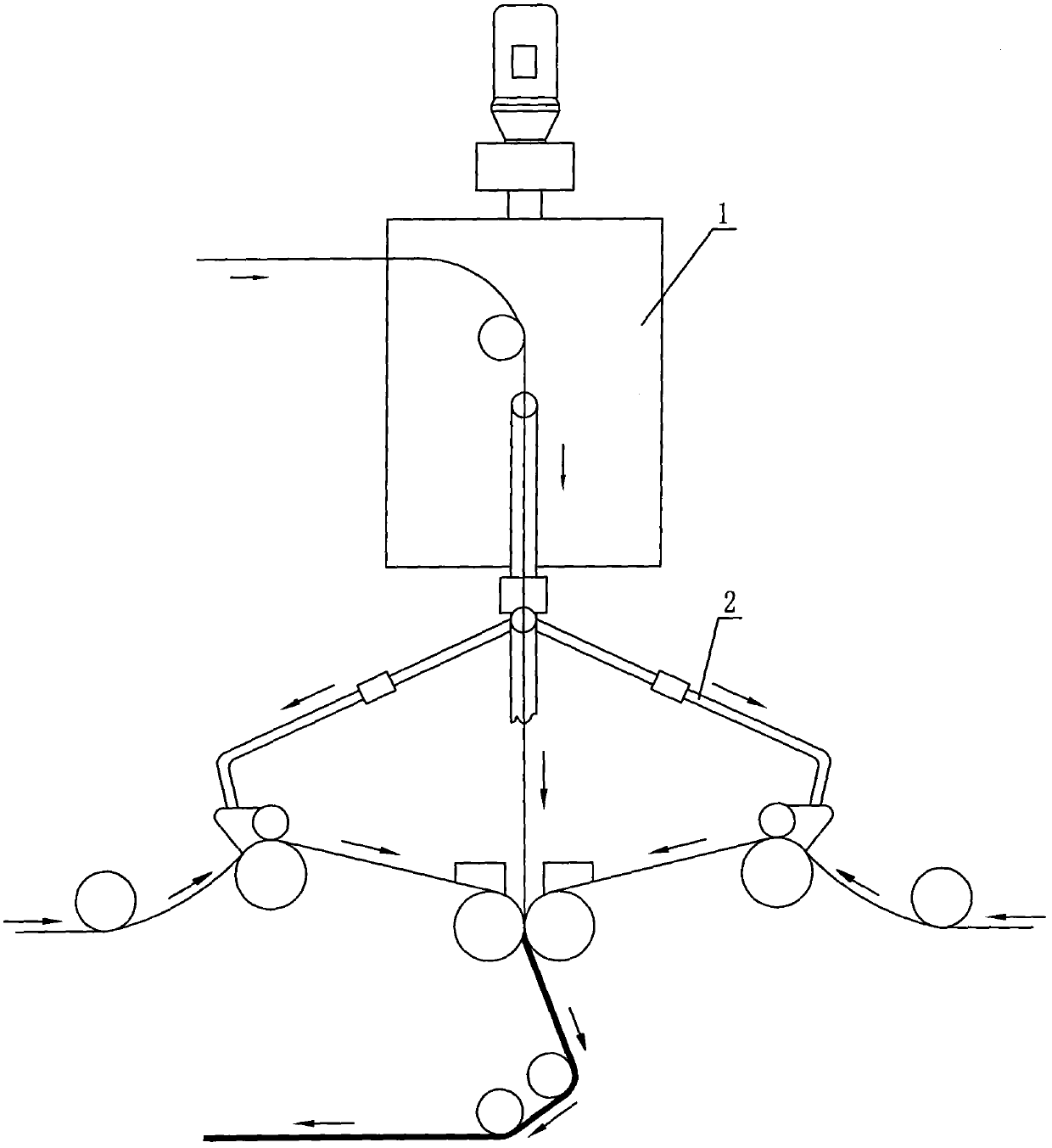

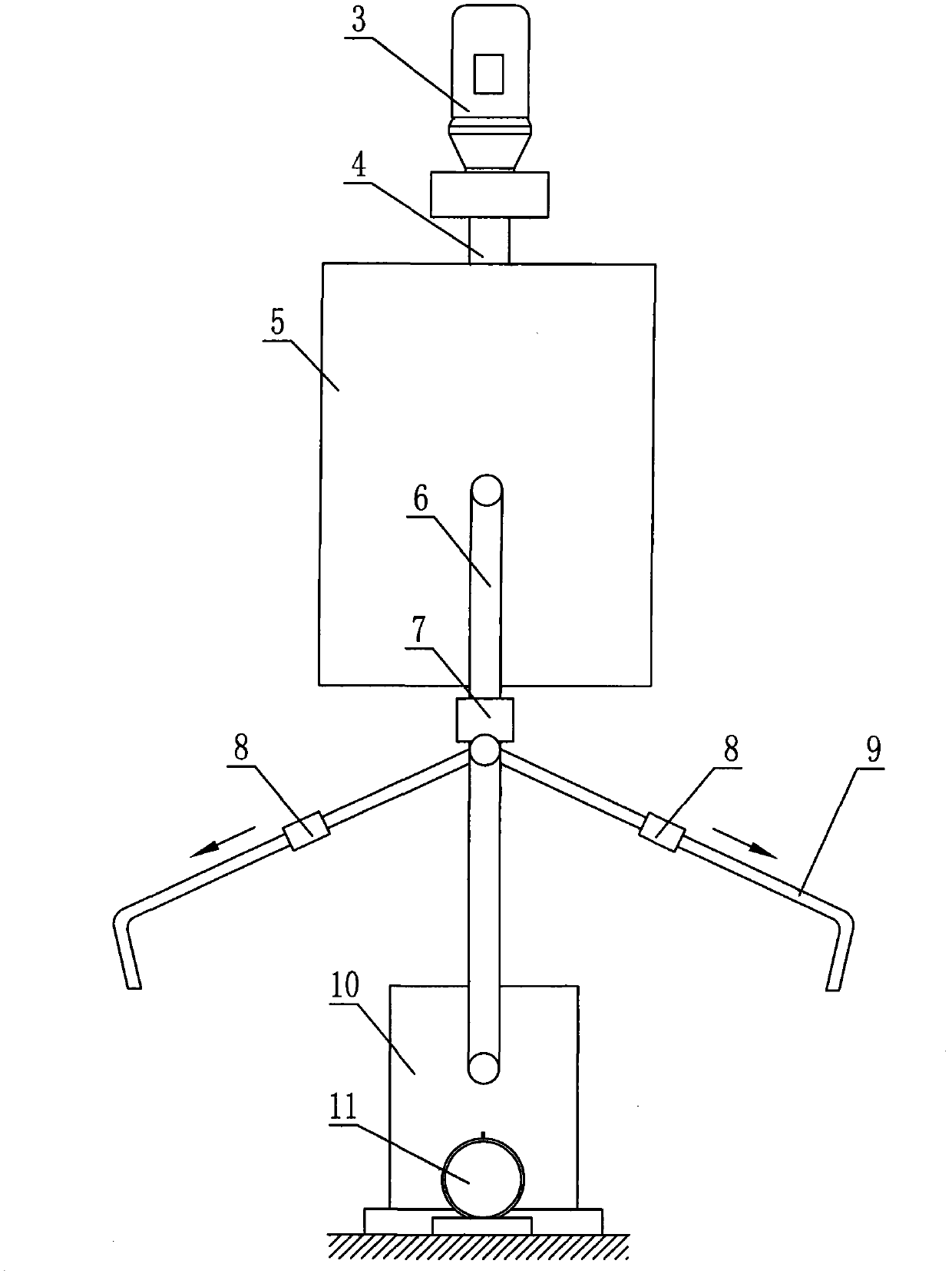

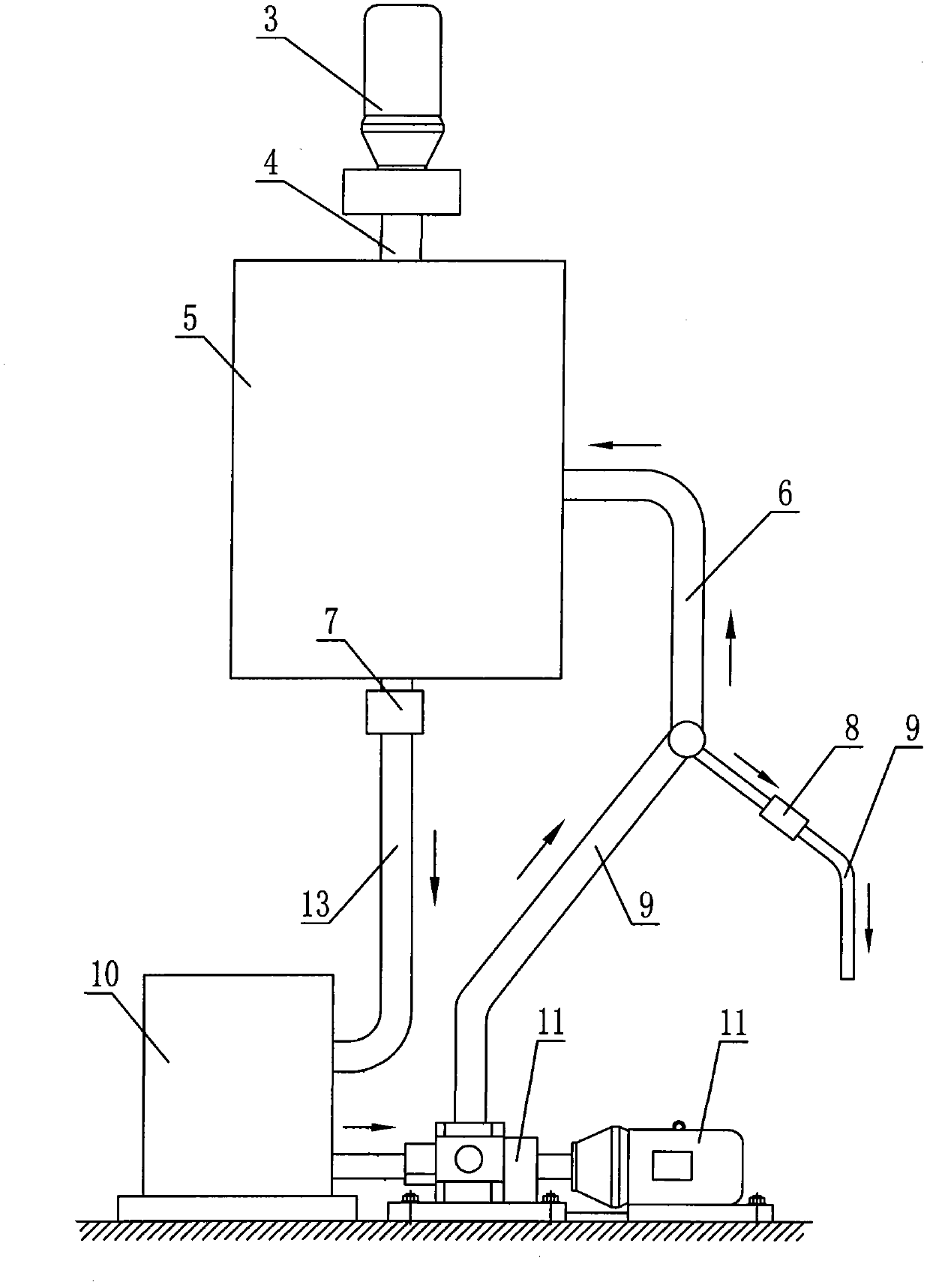

[0038] Scratching points: 1. There is a scraping point on the left and right sides. There are two large rollers 18 of the same size at the scraping point, and the length can be determined according to the product specification. The lower roller drives the main shaft to rotate through the motor, and the upper roller can rotate or not, or manually rotate. 2. The temperature of the modified asphalt is controlled at about 170°C. After it is placed at the scraping point, the lower roller rotates, and the upper roller does not rotate or rotates slowly, thereby driving the upper coating film 16, the lower coating film 21 and the isolation film 15 forward Movement, and "bring" the modified material out, similar to calendering, but there is almost no pressure between the two rollers, so it is a shearing movement. It is equivalent to scraping the modified material on the isolation film, which not only ensures that the modified material can be effectively scraped on the isolation film, ...

Embodiment 2

[0041] Similar to the first one, just change the two large rollers at the scraping point into different large rollers 18 and small rollers 25 pairs of rollers, and the film coating system is the same.

[0042] Scratching points: 1. There is a scraping point on the left and right sides. There are two rollers at the scraping point, one big and one small, and the length can be determined according to the product specification. The big roller drives the main rotation through the motor, and the small roller can rotate or not, and it is manually rotated. 2. The temperature of the modified material is controlled at about 170°C. After it is placed at the scraping point, the lower roller rotates, and the upper roller does not rotate or rotates slowly, thereby driving the upper coating film 16, the lower coating film 21 and the isolation film 15 forward Movement, and "bring" the modified material out, similar to calendering, but there is almost no pressure between the two rollers, so i...

Embodiment 3

[0045] The knife coating point consists of a large roller 18 and a rolling plate 26 . Scrape by traction.

[0046] Scratching points: 1. There is a scraping point on the left and right sides. The scraping point is made up of large roller 18 and rolling plate 26, and the length can be determined according to product specifications. The roller drives the main rotation through the motor, and the steel plate does not rotate. 2. The temperature of the modified material is controlled at about 170°C. After it is placed at the scraping point, the scraping roller rotates, and the coating counter-roller 22 at the coating point 20 drives the coating 16. The lower covering film 21 and the isolation film 15 move forward and "bring" the modified material out, which is a shearing movement. It is equivalent to scraping the modified material on the isolation film, which not only ensures that the modified material can be effectively scraped on the isolation film, but also ensures that the iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com