Turbo-charging apparatus for vehicle engine

A turbocharging device, turbocharger technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of reduced supercharging efficiency, longer channel length, slow catalyst activation, etc., and achieves a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

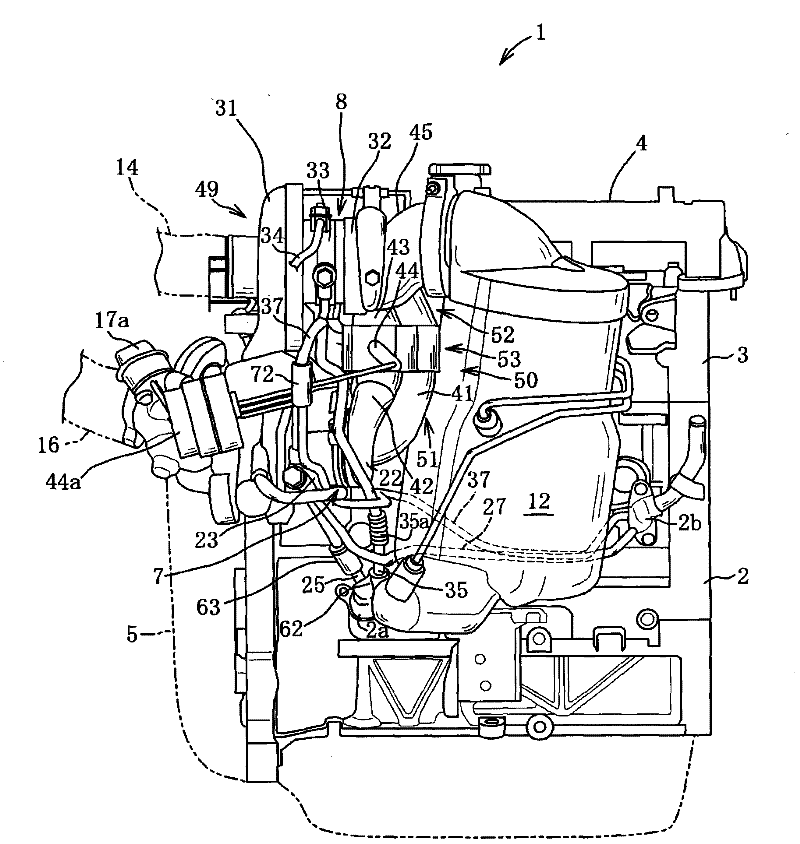

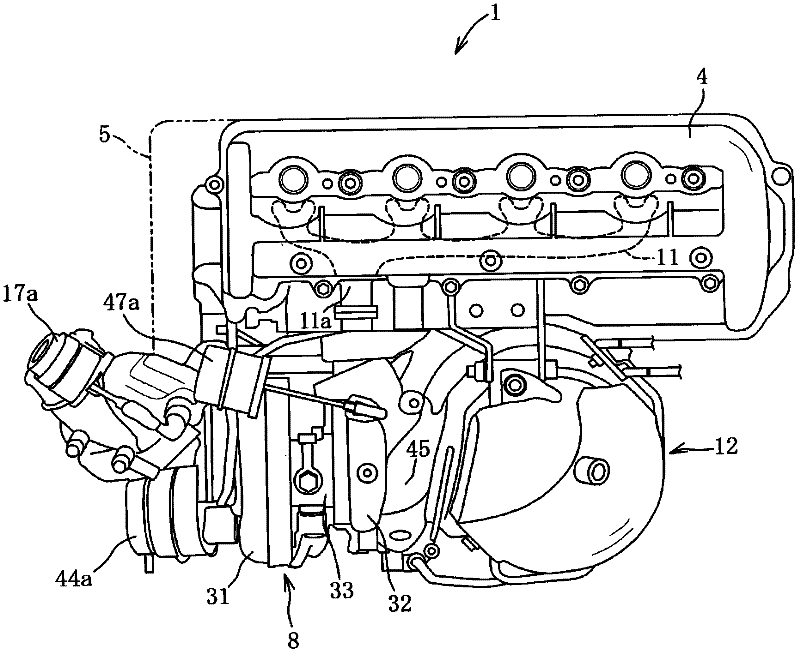

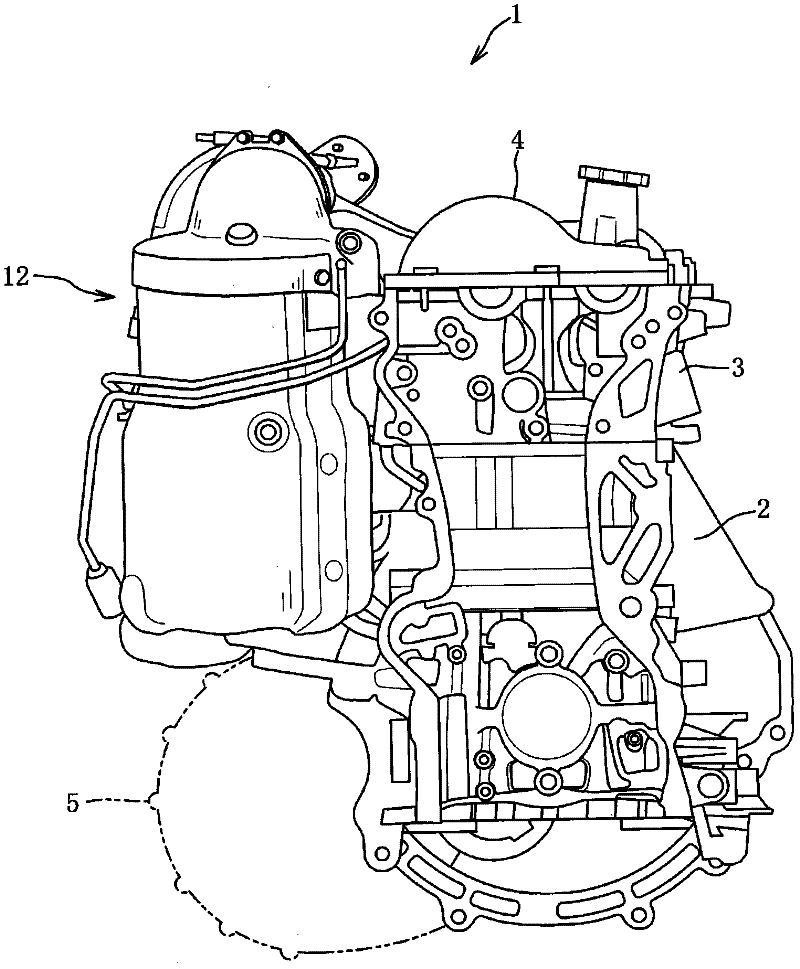

[0045] Below, based on Figure 1 to Figure 18 Example 1 of the present invention will be described.

[0046] Such as Figure 1 ~ Figure 3 As shown, an in-line 4-cylinder diesel engine 1 has a cylinder block 2, a cylinder head 3 disposed on the upper portion of the cylinder block 2, a cylinder head 4 covering the upper portion of the cylinder head 3, and a cylinder head 4 disposed on the left end of the cylinder block 2. Department of the transmission unit 5 and so on.

[0047] The engine 1 is arranged horizontally so that the direction of the crankshaft (not shown) is the direction of the vehicle axis, and the intake port 3a is located on the vehicle front side, and the exhaust port 3b is located on the vehicle rear side. The engine 1 is configured such that the compression ratio in the compression stroke is controlled to be lower than that of a normal diesel engine, for example, the compression ratio is about 14. The transmission unit 5 has a transfer case (not shown) coveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com