Ceramic ball valve

A technology of ceramic ball valve and ceramic valve seat, applied in the field of ceramic ball valve, can solve the problems of inability to adjust the structure, high use cost, short service life, etc., and achieve the effect of prolonging service life, avoiding corrosion and reducing contact seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

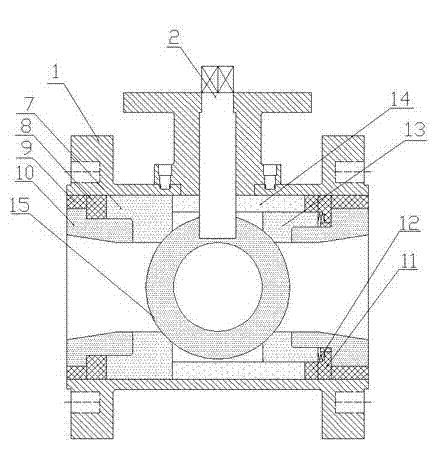

[0016] Embodiment 1, a kind of ceramic ball valve, refer to figure 1 , a ceramic ball 15 is installed in the housing 1, the valve stem 2 is fixedly connected with the ceramic ball 15, the left and right sides of the ceramic ball 15 are respectively provided with a left ceramic valve seat 7 and a right ceramic valve seat 13 in contact with it, The left ceramic valve seat 7 and the right ceramic valve seat 13 are positioned by the metal positioning ring 8. The outer surface of the left ceramic valve seat 7 is in close contact with the inner surface of the housing 1, and the outer surface of the right ceramic valve seat 13 is in close contact with the inner surface of the ceramic middle body 14. The side is in close contact, the other end of the ceramic middle body 14 is in close contact with the inside of the left ceramic valve seat 7, and the right side elevation of the right ceramic valve seat 13 and the ceramic flange lining 10 are provided with a disc spring pressure ring 11,...

Embodiment 2

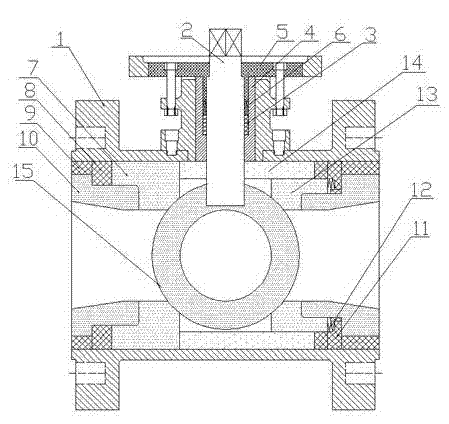

[0017] Embodiment 2, a kind of ceramic ball valve, refer to figure 2 , on the basis of Example 1, the inner side of the cavity where the valve stem 2 is installed is provided with an anti-corrosion sealing layer 4, and the anti-corrosion sealing layer 4 is made of high-performance materials such as tetrafluoro pads, zirconia ceramics, and Haci alloys, This embodiment adopts PTFE pads, etc. on the upper part of the anti-corrosion sealing layer 4. A groove is provided, and an O-ring 3 is installed in the groove, and a rubber pad 6 is arranged above the O-ring 3. The vertical part of the T-shaped pressure plate 5 The plate is divided into a circular body and extends into the installation valve rod 2 cavity to press the rubber pad 6. There is a gap between the horizontal plate part and the shell 1 and is connected by bolts. The shell 1 is an integrated structure, and the others are the same as in Example 1. exactly the same.

Embodiment 3

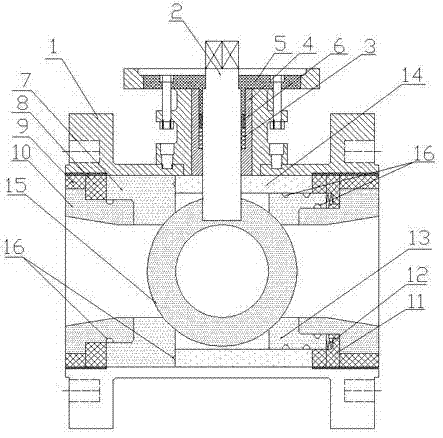

[0018] Embodiment 3, a kind of ceramic ball valve, refer to image 3 , is on the basis of embodiment 2, the flange lining metal ring 9, the left ceramic valve seat 7, the ceramic middle body 14 are threadedly connected with the inner side of the housing 1, the left ceramic valve seat 7, the right ceramic valve seat 13 and the ceramic method A sealing ring 16 is provided at the connecting portion of the blue inner lining 10 and the ceramic middle body 14, and the others are completely the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com