Photoetching method

A technology of photolithography and photolithography pattern, which is applied in the field of photolithography, can solve the problems of photolithography pattern peeling and other problems, and achieve the effect of avoiding peeling and steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the solutions of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

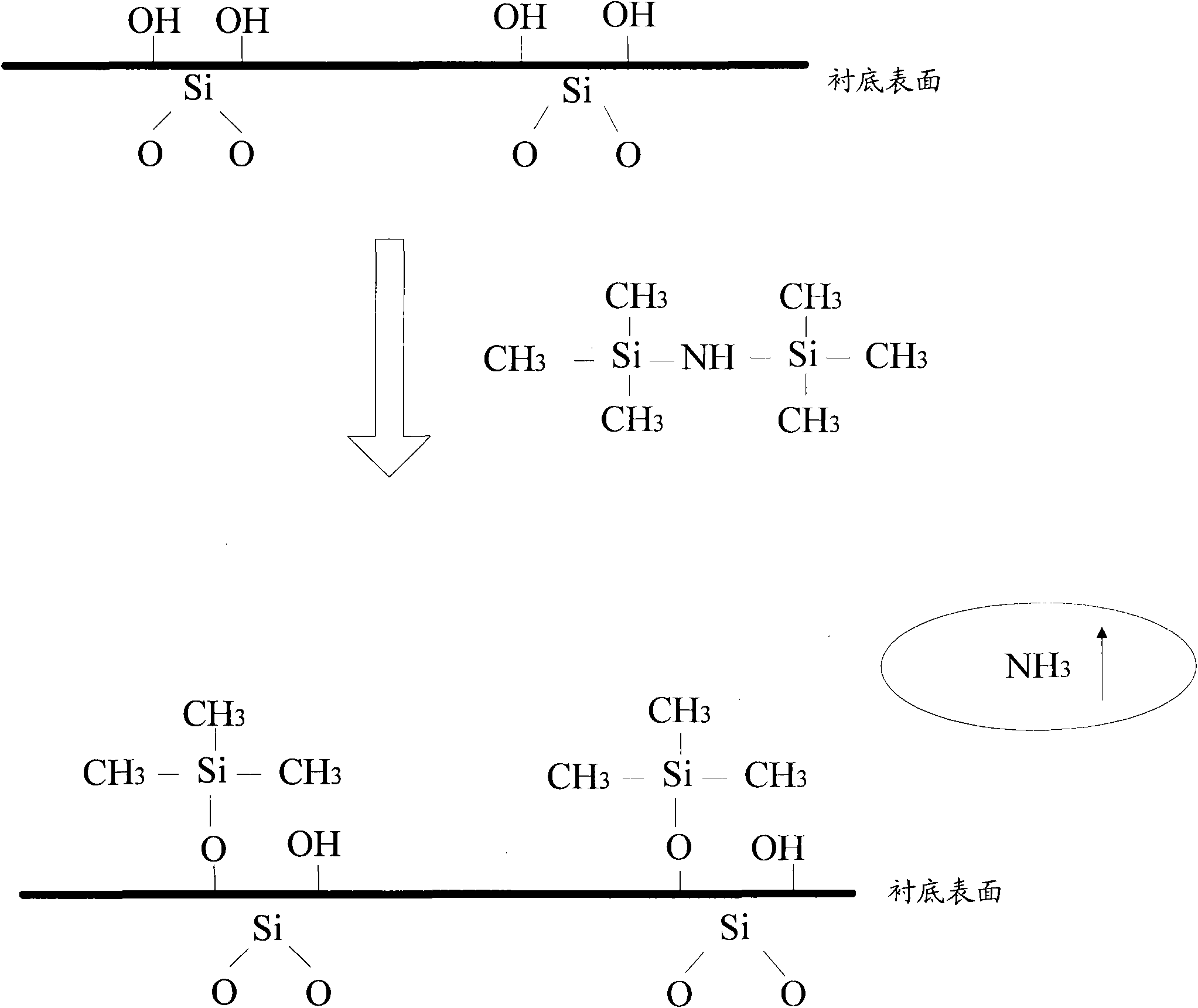

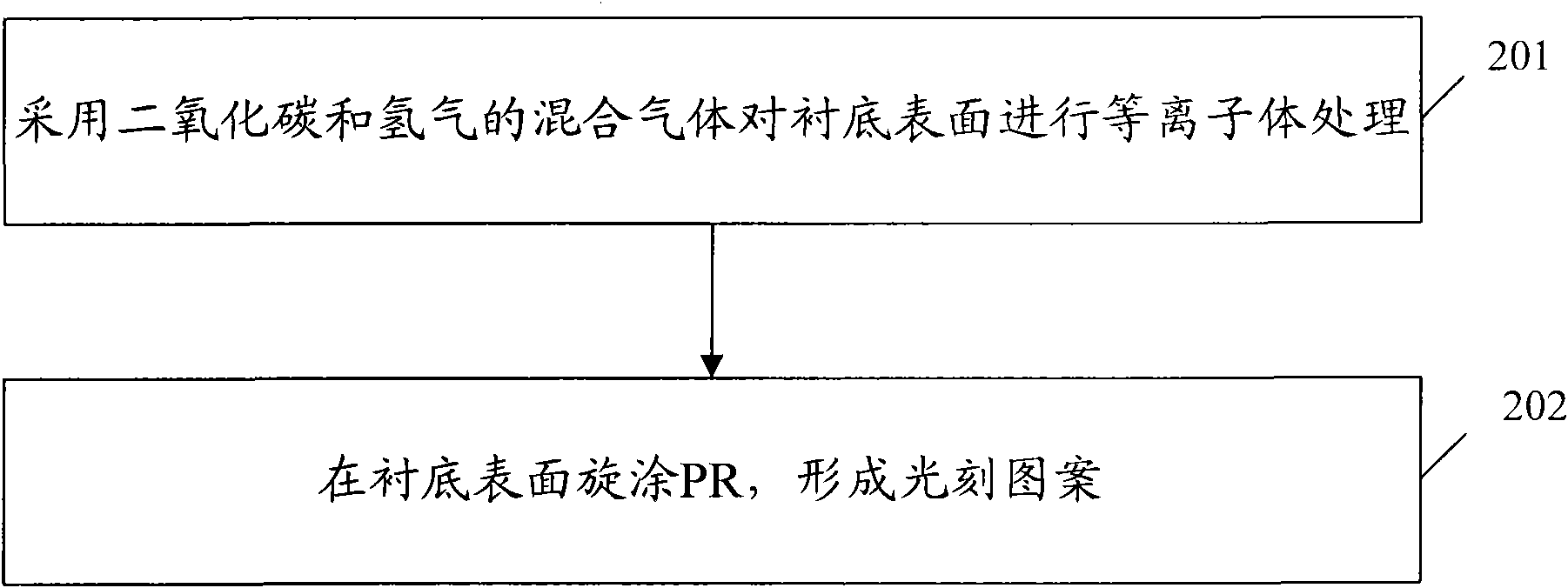

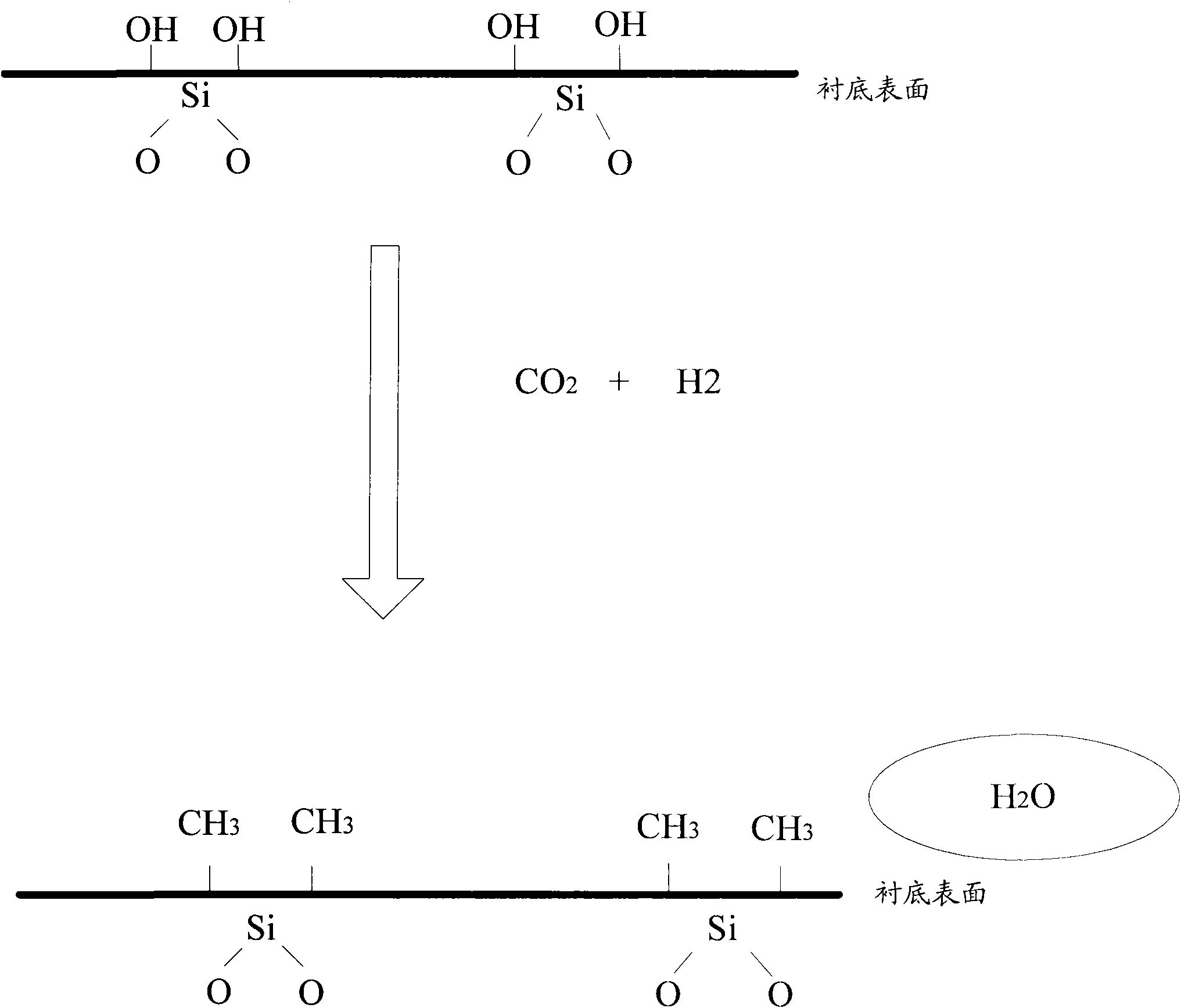

[0027] The core idea of the present invention is: adopt carbon dioxide (CO 2 ) and hydrogen (H 2 ) of the mixed gas on the substrate surface for plasma treatment, the substrate surface and CO 2 and H 2 After the chemical reaction of the mixed gas of the substrate surface, the hydroxyl group on the substrate surface is converted into a methyl group, and the volume of the methyl group is relatively small. When it replaces the hydroxyl group, if there are N hydroxyl groups on the substrate surface, it can also be spaced on the substrate The surface accommodates the substituted N methyl groups, avoiding the steric hindrance effect, and changing the surface of the substrate from hydrophilic to hydrophobic. Therefore, the PR after spin co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com