Method for improving etching repeatability of gallium nitride (GaN) high electron mobility transistor (HEMT) grid trench

A repetitive, gate-groove technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of non-repetitive gate-groove etching, affecting the gate-groove etching rate, affecting the distance between the epitaxial wafer and the upper plate of the ICP cavity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

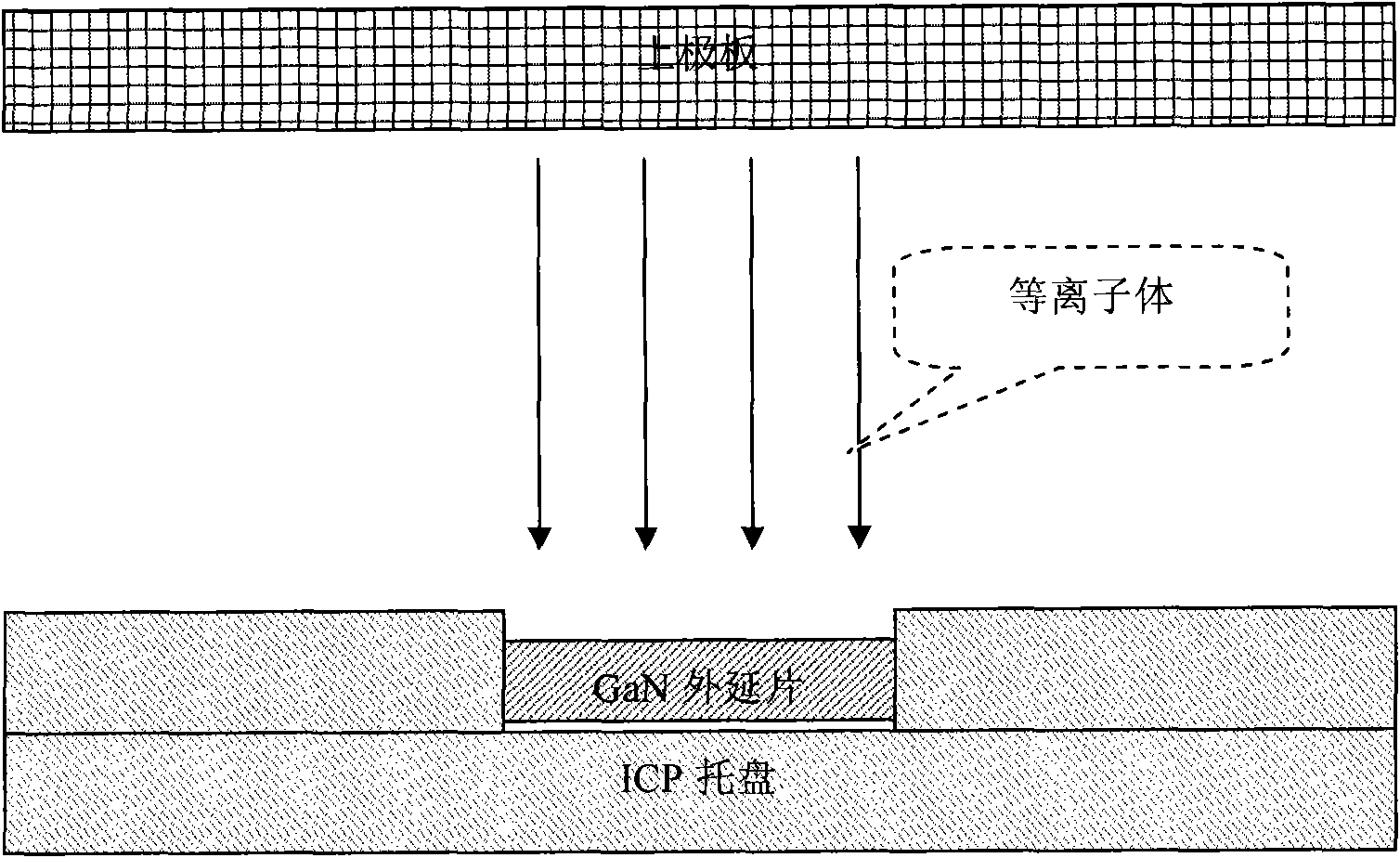

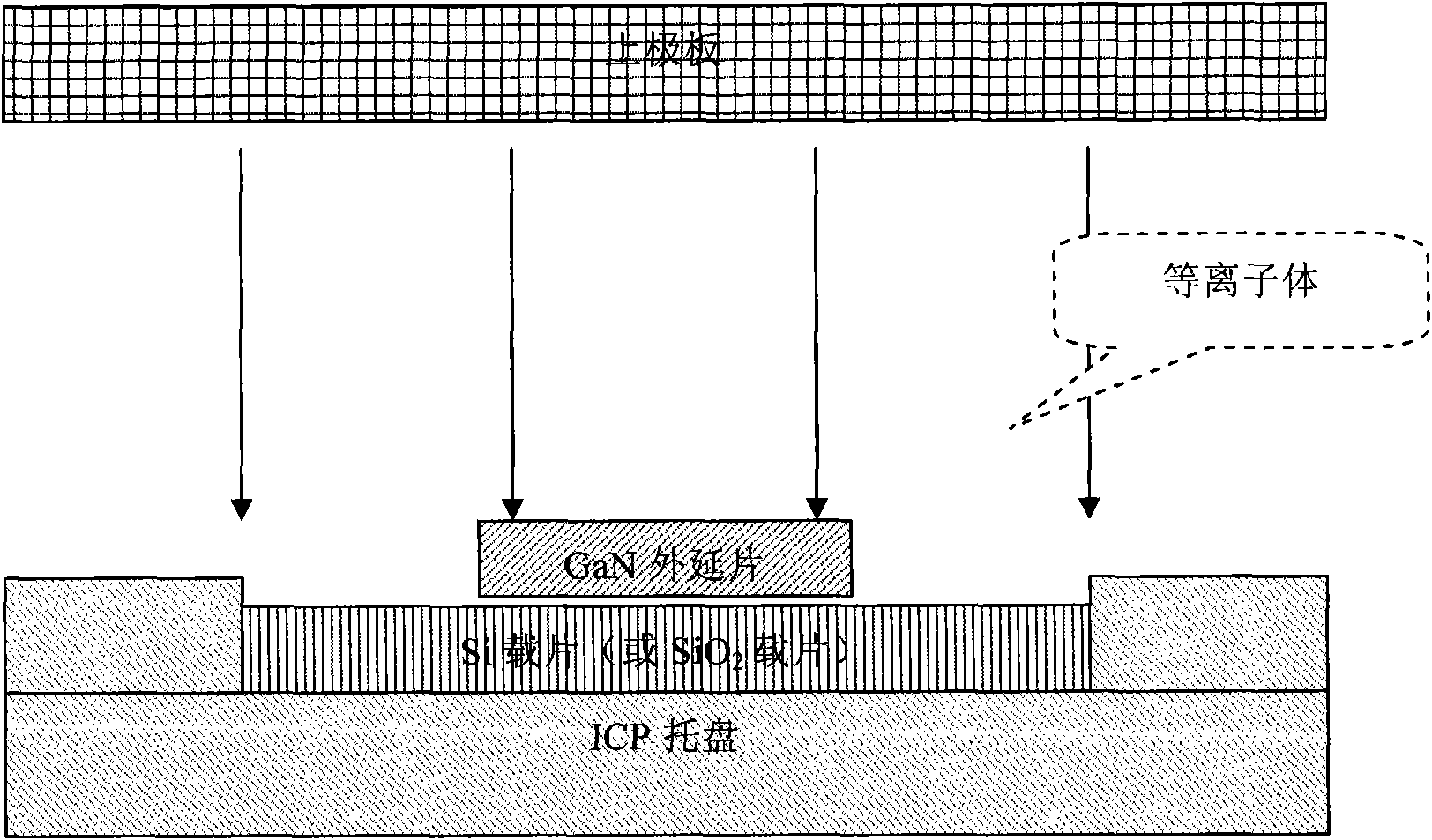

[0025] Aiming at the etching damage and non-uniform and non-repetitive conditions in the traditional GaN HEMT gate groove etching process, the invention adopts a new type of ICP tray to reduce the etching damage and improve the etching uniformity and repeatability.

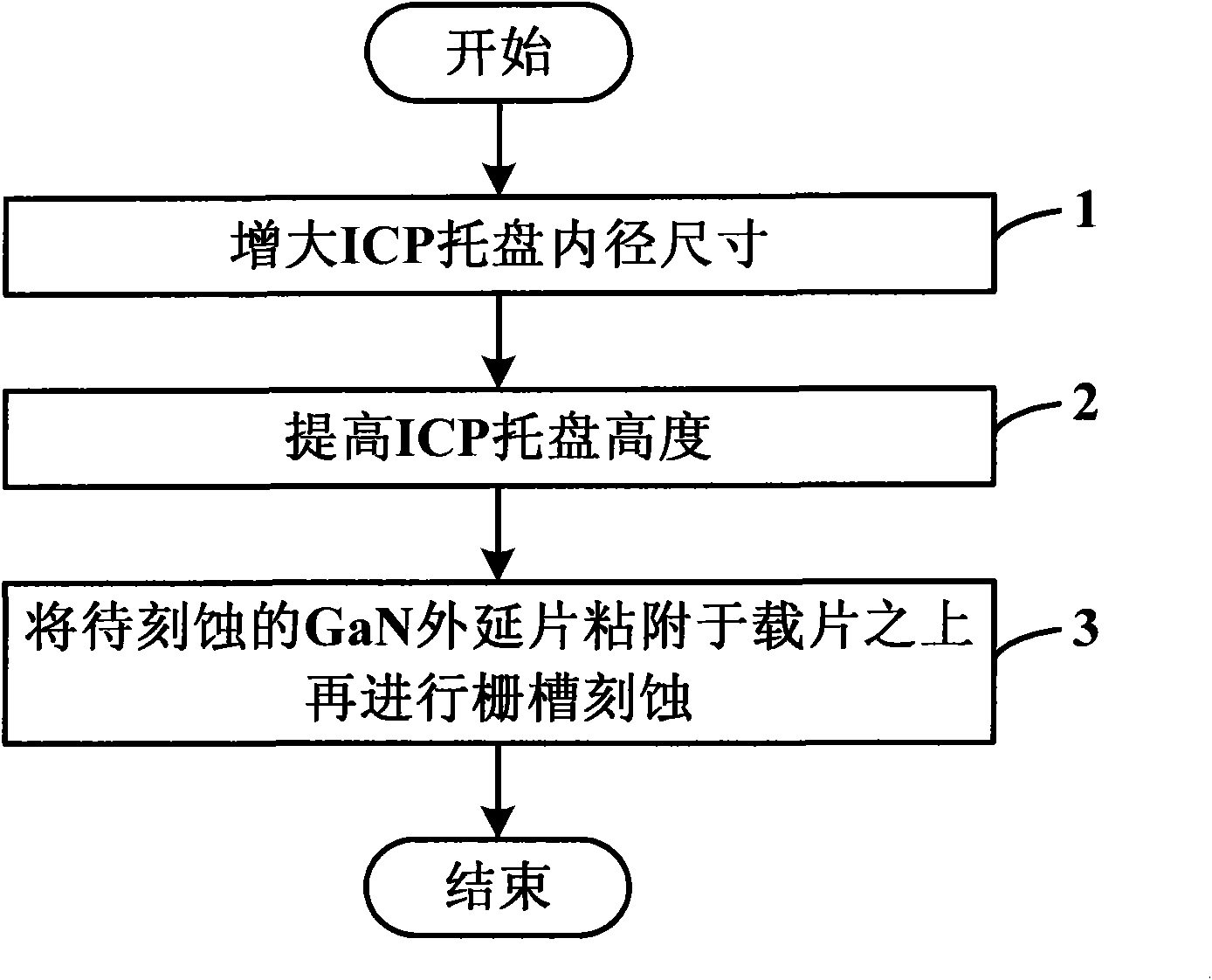

[0026] Such as figure 1 as shown, figure 1 It is a flowchart of a method for improving the repeatability of GaN HEMT gate groove etching provided by the present invention, the method includes:

[0027] Step 1: Increase the inner diameter of the ICP tray;

[0028] Step 2: Increase the height of the ICP tray;

[0029] Step 3: Adhering the GaN epitaxial wafer to be etched on the carrier and then etching the gate groove.

[0030] Among them, increasing the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com